Tungsten Copper Electrode for Arrester

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 November 2016 17:35

Tungsten copper electrode for arrester is also called as surge protector electrode, which protects the devices by conducting and absorbing the energy of thunder. There are some types of arrester:

1. Tube arrester: The principle is that the arc gap set in the arc tube and the gap separate the tube and the grid. It has a large impact flowing capacity, can be used in lightning current amplitude. But it has higher discharging voltage and dispersion and the action will produce cutting wave, so it mainly used in protecting substation, power plant and line insulation;

2. SiC arrester: Stacked in the sealed porcelain sleeve spark gap and silicon carbide valves (high voltage arrester products with multiple porcelain sets). According to the different structure can be divided into two types of ordinary valve and magnetic blow valve, widely used in AC and DC systems to protect power generation, substation equipment, insulation;;

3. Metal oxide arrester: It has better performance than SiC arrester and takes place of it in AC, DC systems, protection of power generation, substation equipment, insulation. Especially is suitable for neutral point effectively grounded 110 kV and above power grid.

There are some essential parameters:

1. Nominal voltage Un: Equipment normal withstand voltage, AC or DC voltage RMS;

2. Maximum continuous operating voltage Uc: Can be permanently applied to the designated end of the protector without causing the protector characteristic change and activating the maximum voltage effective value of the protective element;

3. Nominal discharge current In: also known as the rated discharge current Isn, the protector to the application of the waveform for the 8 / 20μs standard lightning impact 10 times, the protector to withstand the maximum impact current peak;

4. Maximum discharge current Imax: Protector applied to the waveform for the 8 / 20μs standard lightning wave impact 1, the protector to withstand the maximum impact current peak;

5. Response time Ta: The main reaction in the protector of the special protective components of the action sensitivity, breakdown time, in a certain period of time depends on the change du / dt or di / dt slope.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Guide for Electromagnetic Gun

- Details

- Category: Tungsten Information

- Published on Monday, 28 November 2016 17:30

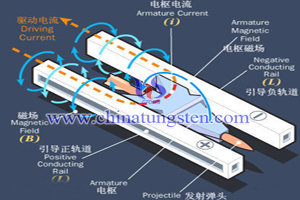

The guide of electromagnetic gun is made by tungsten copper, which uses the magnetic field by strong current and Lorentz force to accelerate the metal missile. Compared with traditional gunpowder propelled artillery, electromagnetic gun has higher speed and wider range.

It has many types, such as:

1. Coilgun: also known as AC coaxial coil gun. It is the earliest form of guns, the projectile acceleration coil and coil. According to the principles of interaction in the magnetic field of the coil is energized and work;

2. Rail guns: it consists of two parallel long straight rail (copper tungsten), with a mass smaller place between the rail slider as the projectile. When the two-track access to power, a strong current from flowing into the rail, the rail slide back into another time from the strong magnetic field generated between the two guide planes through current slide under the action of Ampere force, the projectile will with great speed (the speed of light is theoretically possible to sub-velocity of light) injection, which is the principle launching rail guns, guns rail gun is the most common pattern;

3. Electric guns: the principle is different from the coil gun and rail gun, which uses a general barrel, the inner tube is provided with plasma to the electrode on the burner, the burner is installed at the end after the gun breech. When the plasma burner between the two poles plus high pressure, it will produce an arc, so that the plasma generating material placed between the poles (such as polyethylene) and evaporated. After evaporation material becomes superheated high-pressure plasma, so that the projectile acceleration;

4. Reconnection gun: a multi-stage acceleration of non-contact electromagnetic launchers, not the barrel, but requires projectile gun before entering the reconnection should be a certain initial velocity and it is the latest development in the form of guns.

In addition, it has many advantages:

1. Gun uses electromagnetic force work done as a transmission of energy; it does not produce a strong shock wave and diffuse the smoke, which has a good concealment;

2. It can adjust the range according to the distance of target and proper energy;

3. The projectile has small size and light weight so that it has small air resistance, perfect emission stability, high initial speed and long range;

4. All guns emission process is controlled by computer and equipped with a laser-guided warheads, or other guidance device, it has a high shooting accuracy.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Military Shell

- Details

- Category: Tungsten Information

- Published on Monday, 28 November 2016 17:17

Tungsten copper military shell is also called as electrical packaging shell, which is encapsulation of semiconductor chip, integrates and provides mechanical support and protects electrical, thermal path. Besides, it can directly have an effect on electrical, thermal, optical and mechanical properties of the device.

Tungsten copper military shell material mainly includes ceramic shell, metal shell and ceramic-metal shell. Ceramic shell: Small and medium-scale integrated circuit package (ceramic dual in-line housing, ceramic flat shell, ceramic pin grid array), large and ultra-large scale integrated circuit package (leadless chip carrier, leaded chip carrier, a ceramic flat sides of the lead shell, ceramics ball grid array housing, hermetic encapsulation shell shaped), discrete components package (surface mount type, cartridge type), hybrid circuit package (surface mount type, cartridge type), MEMS device package, a multilayer ceramic substrate ( MCM-C multilayer ceramic substrate, micro-assembly of the substrate);

Metal shell: Optoelectronic device packages (with light window type, with lens type with fiber type), discrete package (A, B type, C type), hybrid circuit package (flat type, cavity line type, flat type), special element package (matrix type, multi-layer multi-cavity type, non-magnetic material type);

Ceramic-metal shell: Discrete package (coaxial, strip line, surface mount type), microwave MMIC package device (carrier, ceramic, metal), hybrid circuit packages, optoelectronic device package (butterfly-shaped, dedicated structure).

With the tendency to multi-functional, high-performance, small size of military electronic equipment, tungsten copper military shell also improved to meet high-power requirement. In order to meet the development needs of microwave and millimeter wave devices and components, the development of low-temperature co-fired ceramic shell technology; In order to meet the development needs of high-power devices and circuits, the development of high thermal conductivity aluminum nitride ceramic packaging technology and high thermal conductivity aluminum shell silicon carbide metal encapsulation shell technology; In order to meet the high-density circuits and components development, the development of fine pitch leaded four sides flat pack housing, high-density ball grid array package shell technology and 3D packaging technology; In order to meet the development needs of high integrated circuit and small modules, developed multi-core package system package and so on.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Rod for Discharge Tube

- Details

- Category: Tungsten Information

- Published on Monday, 28 November 2016 17:10

Discharge tube is a kind component that used in input for preventing from the high voltage. When it is higher than the voltage over its protection standard value, it will be an internal short circuit, and absorbed input high pressure. Tungsten copper rod for discharge tube uses high purity W and Cu powder by isostatic pressing, high-temperature sintering, infiltration, which has excellent conductivity and arc erosion resistance. Tungsten copper rod used as the electrode of high voltage discharge, the temperature of contact material will increase to thousands degrees Celsius in a very short time, which provides the essentials for discharge tube working steady. In addition, tungsten copper material can guarantee the hermeticity between shell sealed and discharge gap, which is suitable for various gas and changing pressure.

According to the content, discharge tube can be divided into gas discharge tube and semiconductor discharge tube.

Gas discharge tube: it main consists of inert gas sealed and sintered by metal wire. The working principle is: when voltage is applied to both ends of the gas discharge tube voltage reaches the gas is ionized, the gas discharge tube of a non-self-sustained discharge transition to self-sustaining discharge, the discharge was low resistance conducting state, you can instantly by a large current, the gas discharge tube after breakdown low voltage can be maintained to less than 30V;

Semiconductor discharge tube: it is composed by solid four-layer SCR (Silicon Controlled Rectifier) structure. Discharge starts operation when the surge voltage exceeds the break-over voltage semiconductor discharge VBO, when the discharge tube operates in the fold-back device, the role of the voltage across the discharge tube is maintained at a very low (approximately 20V or less) can maintain its low resistance state, absorb surge and protect the devices.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Resistance Welding Rod

- Details

- Category: Tungsten Information

- Published on Friday, 25 November 2016 14:33

Tungsten copper resistance welding rod has excellent thermal and electrical conductivity, which uses the resistance heat current run through the contact area and near to turn into melting or plastic state and combine the metals. It plays an important role in pushing the welded component with high pressure, providing a large amount of welding current on the part of welding and promoting the cooling process on the welded component.

According to the methods of welding, tungsten copper resistance welding rod can be specifically divided into spot welding rod, seam welding rod, projection welding rod, butt welding rod.

1. Spot welding rod: The weldment assembled into lap joint, and pressed between two cylindrical electrodes, the use of hot-melt resistance of the base metal to form a solder joint resistance welding method used for welding sheet metal;

2. Seam welding rod: It is similar to spot welding process, except that uses disc-shaped roller electrode instead of cylindrical electrode. The weldment assembly into a lap or butt joints, and placed between two electrode rollers, roller pressing and weldment rotation, continuous or intermittent power transmission, forming a continuous weld seam, which is mainly used for more regular and sealing high performance requirements of the structure;

3. Butt welding rod: The weldment welded along the entire contact surface;

4. Projection welding rod: A variant form of spot welding; on a workpiece has preformed bumps, when the projection welding, one can form one or more of the nugget at the joint.

In addition, tungsten copper resistance welding rod has many advantages compared with other materials, such as:

1. Nugget formed, is always surrounded by a plastic ring, molten metal and air separation, metallurgy process is simple;

2. Heating time is short, heat concentration, it is a small heat-affected zone, deformation and stress is also small, usually do not have to arrange correction after welding and heat treatment process;

3. It does not need welding wire, rod and other metal stuff or oxygen, acetylene, hydrogen, so the welding costs if relatively low;

4. High efficiency, no pollution and is suitable for mass production.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper EDM Rod

- Details

- Category: Tungsten Information

- Published on Friday, 25 November 2016 14:28

Tungsten copper EDM rod has excellent thermal and electrical conductivity, arc erosion resistance and high material removal rate. Especially for tungsten carbide, high-temperature hard alloy mold manufacturing has remarkable performance.Tungsten copper materials used for electrode accounts for a quarter of total consumption of tungsten copper, so it not only required high conductivity, material removal rate, low electrode consumption, easy for processing, but also has requirements as follow:

1. Based on high thermal and electrical conductivity, it also obtains better performance in arc erosion resistance;

2. It is difficult to meet the requirements of the contact by normal process, tungsten copper electrode should has uniformity and high density;

3. It is the most out standing problem that the mold or other products with diverse shape or structure needs different kinds of tungsten copper electrode, but the quantity demanded is relatively low.

Electric discharge machining (EDM) is a non-traditional type of precision processing using an electrical spark-erosion process between the electrode and the working piece of electrically conductive immersed in a dielectric fluid. Since it has more special gains, the EDM has been widely applied in modern metal industry for producing complex cavities in moulds and dies, which are difficult to manufacture by conventional machining. The use of EDM in the production of forming tools to produce plastics moldings, die castings, forging dies etc., has been firmly established in recent years. The EDM is a well-established machining choice for manufacturing geometrically complex or hard material parts that are extremely difficult to machine by conventional machining process. Its unique feature of using thermal energy to machine electrically conductive parts regardless of hardness has been its distinctive advantage for manufacturing of mold, die, automotive, aerospace and surgical components. Thus, titanium and titanium alloy, which is difficult-to-cut material, can be machined effectively by EDM.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Throat Insert

- Details

- Category: Tungsten Information

- Published on Friday, 25 November 2016 13:50

Tungsten copper throat insert is lining material of solid rocket motor nozzle, and its high temperature performance and ablation resistance directly affects the thrust and efficiency of the engine. Solid rocket motor nozzle by controlling the expansion of the combustion chamber exhaust gas generated energy is efficiently converted to kinetic energy, so as to provide the required power for the aircraft. The throat insert is located in the nozzle throat, and its main role is to limit the throat area due to erosion produced by increasing phenomenon, caused by the thrust decreases. When the engine is working, throat insert often require direct heating from room temperature to greater than 2000 ℃, resulting in significant temperature gradient and thermal stress, which is the main reason for failure of the crack and working throat lining material appears. In addition, for this type of high-performance rocket engines commonly used metal powders (such as Al) as propellants combustion at high temperature of about 3000 ℃ high burning rate entrained flow of solid particles or liquid droplets Al2O3 severe erosion. If lining severe erosion is difficult to ensure a stable aerodynamic shape even fragmentation occurs, it will directly affect the thrust and efficiency of the engine.

Generally speaking, throat lining material for the solid rocket motor comprising refractory metal, graphite, carbon and carbon-based composite materials, reinforced plastics, ceramic matrix composite materials. Throat heat transfer can be divided into three stages: 1. engine ignition instant impact heating; 2. ablation steady when working; 3. flameout cooling. Tungsten copper material not only has high hardness, high density, high strength, high melting point, low thermal expansion coefficient and excellent wear and corrosion resistance, also has good ductility and electrical and thermal conductivity. And since the large difference of two kinds of metals, at higher than the melting point of copper, copper is evaporated away to leave most of the heat of the hard phase tungsten throat insert to ensure the stability of working.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Military Nozzle

- Details

- Category: Tungsten Information

- Published on Friday, 25 November 2016 11:06

Tungsten copper military nozzle is kind of device accelerating air by changing the shape of inner wall, which has high hardness, high strength, high softening temperature, low coefficient of thermal expansion and excellent arc breaking performance. So it plays an important role in military high temperature and spiral accelerated pipeline.

Tungsten copper military nozzle has many types, according to the specific performance of aircraft and engine, it can be specifically divided into fixed or adjustable convergent nozzle, convergent-diffused nozzle, eject nozzle and adjustable nozzle, etc.

Convergent nozzle: sectional area of the flow direction gradually reducing, in large mach flying, incomplete expansion will cause great loss of thrust;

Convergent-diffused nozzle: also known as Laval nozzle, is a kind of nozzle cross-sectional area diffuses after convergent, mainly used in supersonic fighter, the critical area and exit area are required to fly with the state regulation;

Eject nozzle: consists of adjustable convergent main nozzle and a fixed or adjustable ejector. It is light and has simple structure, can maintain good performance over a wide range of flight, it has been widely used in many high performance aircraft;

Adjustable nozzle: mainly used for high-speed flight afterburning turbojet aircraft or military afterburning turbofan engine. Easy to adjust nozzle area ratio, may vary with flight conditions, and often in a fully expanded state. Structure type balanced rod, folding, folding petal sleeve cone and so on.

Tungsten copper military nozzle expansion accelerated as the airflow at a high speed jet and counter productive outward thrust. Most high-speed fighter uses adjustable nozzle and adjustable convergence-diffusion nozzle or ejector nozzle; common fixed convergent rocket engine-diffusion nozzle; vertical or short takeoff and landing aircraft using commutation nozzle. In addition, In the ASRM (Advanced Solid Rocket Motor) the front nozzle is also used tungsten copper material.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nano Tungsten Probe Needle Production Methods

- Details

- Category: Tungsten Information

- Published on Friday, 04 November 2016 16:57

Tungsten wire is used for nano tungsten probe needle production and there are many production methods, such as: mechanical shearing method, mechanical grinding method, field evaporation method, ion bombardment method, electric spark machining method, electrochemical etching method and so on. The most commonly used production method is electrochemical etching method. This method is simple in production principle and production equipment, easy to realize, good in controllability and low in cost, so it is widely used. Electrochemical etching method can be divided into: AC-DC sharing method, magnetic field enhancement method, liquid film method, reverse electrochemical method, the lower end etching method and pulse electrochemical machining method. The above methods control the shape and aspect ratio of the tungsten probe needle by changing the concentration of the solution, the depth of immersion, the corrosion voltage and the duty cycle of the pulse voltage. However, during the etching process, the tungsten filament is stationary, so the shape of needle is exponential type and the adjustable range of aspect ratio is small.

New nano probe needle production method is to use single clip microcomputer stepper motor shaft lifting up tungsten wire with uniform velocity and to control the parameters of the electrochemical corrosion, so it can produce different aspect ratio nano tungsten probe needle and the tip radius of curvature can up to 30nm, which can meet different application requirement. Nana tungsten probe needle production processes are as follows:

1. Firstly, use electro corrosion for removing tungsten wire surface oxide layer, and then to clean it. That is tungsten wire as the anode, copper rod as the cathode, placed in NaOH aqueous solution (2mol / L), 2.5mm-9mm immersion depth of the anode and 40mm of cathode, passed IOV AC, for 30-100S corrosion, so it can remove the tungsten wire surface oxide layer, and then can use deionized water for cleaning.

2. Secondly, cleaned tungsten wire as anode and copper rod as cathode, placed in corrosion solution (2mol / L sodium hydroxide solution), turns on the power to start corrosion, while uses single clip microcomputer stepper motor shaft to lift up tungsten wire with uniform velocity and the part of the tungsten wire is kept in the solution at all times. After finished lift up we should stop the wire in the solution till the tip of the tungsten wire to fall off to obtain the nano tungsten probe needle.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode Diameter Selection and Tungsten Electrode Packaging

- Details

- Category: Tungsten Information

- Published on Monday, 31 October 2016 18:24

The tungsten electrode is divided into different types according to different raw materials and doping elements, including pure tungsten electrode, thorium tungsten electrode, lanthanum tungsten electrode, zirconium tungsten electrode, yttrium tungsten electrode, cerium tungsten electrode and composite electrode. Due to their different materials and doping elements, different tungsten electrode has different characteristics and its applications are also different. In the tungsten electrode series, pure tungsten electrode is the cheapest, usually used in aluminum, magnesium alloy welding. Yttrium tungsten electrode in the welding process has slim arc, high compressive strength and high penetration in welding, which is mainly used in military and aviation industry. Thorium tungsten electrode overall performance is good and it has good performance in the overload, generally used for carbon electrode and stainless steel, nickel alloy and titanium electrode welding in the negative or positive electrode of direct current. Lanthanum tungsten electrode conductivity is generally good for welding carbon, stainless steel, nickel alloy and titanium. Cerium tungsten electrode can arc easily and also can stable maintain the arc, usually used for TIG welding, plasma welding, plasma cutting, plasma spray coating, plasma smelting and gas discharge light source. Composite tungsten electrodes added with two or more rare earth oxides has good welding performance which is better than thorium tungsten electrodes.

Tungsten electrodes common diameters are 0.5 ~ 50 mm and lengths are 150 mm, 175 mm and 178 mm. In the welding process, in different welding current tungsten electrode diameter is different, so tungsten electrode diameter selection depends on current.

|

Diameter |

DC(A) |

AC(A) |

|||

|

in |

mm |

Cathode(-) |

Anode(+) |

Asymmetric waveform |

Symmetric waveform |

|

0.04’’ |

1.0 |

15-80 |

|

10-80 |

20-60 |

|

1/16 |

1.6 |

60-150 |

10-18 |

50-120 |

40-100 |

|

0.079 |

2.0 |

100-200 |

12-20 |

70-160 |

60-130 |

|

3/32 |

2.4 |

150-250 |

15-25 |

80-200 |

80-150 |

|

1/8’’ |

3.2 |

220-350 |

20-35 |

150-270 |

120-200 |

|

5/32’’ |

4.0 |

350-500 |

35-50 |

220-350 |

170-260 |

|

3/16’’ |

4.8 |

420-650 |

45-65 |

240-420 |

220-340 |

|

1/4’’ |

6.4 |

600-900 |

65-100 |

360-560 |

250-450 |

Tungsten Electrode Packaging: Tungsten electrode packaging depends on the size of the product. Conventional electrodes of 150 and 175 mm length are available in plastic boxes with 5 / box and 10 / box. When the electrode length is longer, such as 200mm, 300mm, 400mm, 450mm, etc. can be bundled through the plastic film and packed with plastic box. This method can also be used in electrodes with a shorter length, which can save a fraction of the shipping cost.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com