Tungsten Electrodes For Tungsten Inert Gas Welding(TIG)

- Details

- Category: Tungsten Information

- Published on Monday, 31 October 2016 17:57

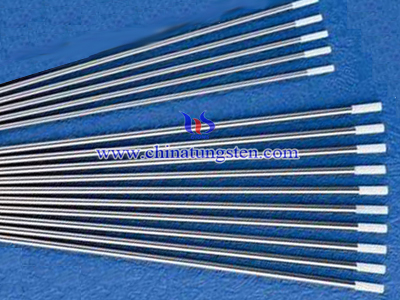

Tungsten electrode commonly used in tungsten inert gas welding (TIG) includes thorium tungsten electrode, cerium tungsten electrode, lanthanum tungsten electrode, zirconium tungsten electrode, yttrium tungsten electrode, composite tungsten electrode and pure tungsten electrode. Different tungsten electrode has different characteristics, the user can choose according to the requirements. The commonelectrode diameter and length is generally φ0.5-50mm, length: 150mm, 175mm and 178mm. The following will introduce the main features of TIG used tungsten electrode series.

Cerium tungsten electrode: Cerium tungsten electrode is kind of green product, whichdoes not have radioactive contamination. In the case of very small current it can arceasily and the arc current is also less than other tungsten electrode. In the low-current DC conditions, cerium tungsten electrode is more suitable than other tungsten electrodes, which can be used for small pipes and small parts of the welding.

Thorium tungsten electrode: Thorium tungsten electrode is the most widely used electrode among tungsten electrode series, due to its excellent overall performance,which can withstand the overload current. However, currently thorium tungsten electrode is subject to certain restrictions, because it has a slight radioactive contamination, so the user commonly used cerium tungsten electrode and lanthanum tungsten electrode instead of thorium tungsten electrode.

Lanthanum tungsten electrode: lanthanum tungsten electrode has good welding performance and its conductive property is closest to 2% thorium tungsten electrode,which does not have radioactive contamination. In the welding process, the user does not need to change any welding procedure can be quickly and easily to replacethorium tungsten electrode, so the lanthanum tungsten electrode is the best product toreplace thorium tungsten electrode. It is mainly used for DC welding, but can also be used in AC welding, and performed well.

Zirconium tungsten electrode: Zirconium tungsten electrode in the AC has stableperformance. In the welding process, the welding point can be maintained spherical, and the arc is stable. In the high load conditions, the arc is also stable, which is better than other types of tungsten electrodes. In addition, it also has good corrosion resistance property, so it is suitable for magnesium and its alloys AC welding.

Pure tungsten electrode: Pure tungsten electrode is cheap, suitable for alternating current, for magnesium, aluminum and its alloys.

Yttrium tungsten electrode: Yttrium tungsten electrode during welding the arc isslender, large degree of compression, and especially in the large current has maximumpenetration, mainly for military and aerospace industries.

Composite electrode: In the tungsten substrate added two or more rare earth oxides, the additives complement each other, so it has better overall performance and welding performance is better than thorium tungsten electrode.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Granule

- Details

- Category: Tungsten Information

- Published on Monday, 31 October 2016 17:53

Tungsten granule, also known as tungsten flux, the color is bright gray and the appearance is polyhedral particles. Besides, the particle size is about 20-40 mesh, high purity, which can up to 99.95% or more, so it is also known as pure tungsten flux. It is made of metal tungsten processed to the small particles, because it has a good flux effect and in the analyzer the measured results are very stable, which is widely used. The main purpose is as flux used in infrared carbon and sulfur analyzers. Tungsten granule used for the infrared carbon and sulfur oxides analysis, which helps to reduce the melting point of combustion products and promote the release of carbon and sulfur. The principle is as follows: tungsten is easily oxidized, to pass oxygen at 650 ℃ the tungsten will be oxidized and can release a lot of heat, with a high heat value, fast response characteristics. Oxygenated product tungsten trioxide is an acidic oxide with loose volume, so it is conducive to release CO2 and SO2 and will not cover on the sample. Tungsten trioxide above 900 ℃will significantly sublimation. Due to the escape of tungsten trioxide, to increase the diffusion rate of carbon and sulfur, the sample can fully oxidize. In addition, the volatilized tungsten trioxide after leaving the molten pool, at 700 ~ 800 ℃ turns into a solid phase, covered on Fe2O3 where in the pipeline to prevent sulfur adsorption of pipeline. And tungsten baseline value is very low, can be used for low carbon and low sulfur determination.

Tungsten billet and tungsten powder can both as raw materials for tungsten flux production. Tungsten billets are mainly uses tungsten (broken) head. Tungsten billet is generally used for the production of tungsten wire, mixed with trace elements aluminum, silicon, potassium, volatile high. In addition, can also directly used FW-1 tungsten powder for tungsten flux manufacturing, and the flux performance is than tungsten billet produced flux. Besides, carbon and sulfur baseline value is low, less volatile, but the high cost of raw materials.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Silver Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Monday, 31 October 2016 17:31

Silver tungsten electrode, also known as silver tungsten rod and silver tungsten bar, that is tungsten and silver alloy. Silver tungsten alloy combines the advantages of silver and tungsten, high melting point, high specific gravity, easy cutting, high conductivity, wear resistance, anti-welding, anti-oxidation and so on. It is high smoothness electrode which general processing equipment and tool is difficult to process. In addition, the silver tungsten electrode than the ordinary electrode has a higher finish, can be processed into high-precision products.

Silver tungsten electrode is manufactured by powder metallurgy, and tungsten alloy content is more than 60% usually used soaking method for production. Silver tungsten electrode with high hardness, high arc corrosion resistance, high melting resistance welding properties, often as electrode materials and welding materials. Silver and tungsten alloy after sintered the product has higher conductivity than tungsten copper. Therefore, it is mainly used as a resistance welding electrode used in high oxidation resistance requirements working environment. As the EDM electrode its finish degree is better than copper electrode, so that the mould has very high accuracy. In addition, it is often made into high temperature materials, microelectronic materials, through high current switching applied in the aerospace and aviation, metallurgy, machinery, sports equipment and other fields.

Common silver tungsten electrode product specifications are as follows: AgW30 AgW40 AgW50 AgW55 AgW60 AgW65 AgW70 AgW75 AgW80 AgW85.

Silver tungsten alloy performance indicators:

|

Grade |

Content(wt%) |

proportion(g/cm3) |

conductivity(%IACS) |

Hardness(HB) |

|

AgW60 |

Tungsten:60% |

14.00 |

51 |

125 |

|

AgW65 |

Tungsten:65% |

14.50 |

48 |

135 |

|

AgW70 |

Tungsten:70% |

14.90 |

45 |

150 |

|

AgW75 |

Tungsten:75% |

15.40 |

41 |

165 |

|

AgW80 |

Tungsten:80% |

16.10 |

37 |

180 |

Silver tungsten rod specifications: (unit,mm)

|

D2x200 |

D3x200 |

D4x200 |

D5x200 |

|

D6x200 |

D7x200 |

D8x200 |

D9x200 |

|

D10x200 |

D12x200 |

D14x200 |

D16x200 |

Silver tungsten plate specifications: (unit, mm)

|

Thickness |

Width |

Length |

|

2-50 |

100 |

100 |

|

Customized specification is available |

100 |

200 |

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

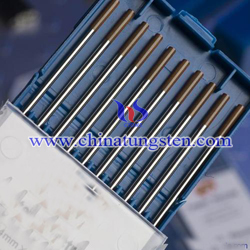

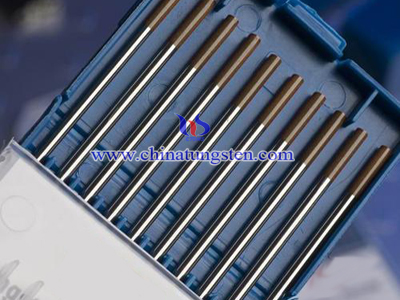

Tungsten Electrode Images

- Details

- Category: Tungsten Information

- Published on Monday, 31 October 2016 16:50

Tungsten electrode images are showing popular used electrodes for welding, esp. TIG.

Pure tungsten electrode is with green tip.

Thorium tungsten electrode is with red tip.

Lanthanum tungsten electrode WL10 is with black tip.

Lanthanum tungsten electrode WL15 is with gold tip.

Lanthanum tungsten electrode WL20 is with blue tip.

Zirconium tungsten electrode WZ3 is with brown tip.

Zirconium tungsten electrode WZ8 is with white tip.

Cerium tungsten electrode WC20 is with grey tip.

Yttrium tungsten electrode is with blue tip.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

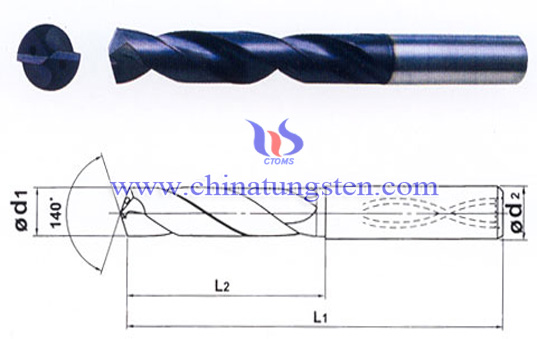

Tungsten Carbide Coolant Feed Drill

- Details

- Category: Tungsten Information

- Published on Thursday, 27 October 2016 18:34

Tungsten carbide coolant feed drill has 1 or 2 through-hole or double spiral hole and uses compressed air and cutting fluid to cool tool and take chips away. It is particularly suitable for the deep-hole drilling with great cutting heat. The structure of tungsten carbide coolant feed drill:Tungsten carbide coolant feed drill mainly consists of drill tip, chip groove, spiral groove, run-out groove, handle and cooling hole.

Drill tip: In drilling process, it endures the most part of thrust and torque, which directly affects the quality and the service life of drill;

Run-out groove: It is transitional surface of the spiral groove surface and the outer surface of the drill bit, which mainly used for chipping and can remarkably improve the surface quality and the efficiency.

Maintenance

1. When drilling steel, please ensure that a sufficient amount of cooling and the use of metal cutting fluid;

2. Good rigidity of drill pipe and guide clearance can effectively improve the drilling accuracy and extend the service life;

3. Ensure the flatness and the cleanness between magnetic base and the workpiece;

4. Strengthening the workpiece when drilling sheet or drilling large workpiece;

5. Use compressed air to contribute chipping instead of using coolant when drilling powder materials, such as cast iron, cast copper, etc;

6. Timely remove the chips on the drill to keep the charging smooth.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

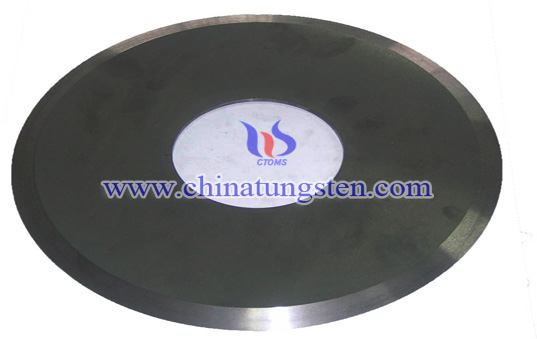

Tungsten Carbide Disc Cutter

- Details

- Category: Tungsten Information

- Published on Thursday, 27 October 2016 18:30

Tungsten carbide disc cutter is fabricated by pressing and sintering process, which has good toughness, abrasion resistance, anti-oxidation and crater wear resistance. So it can be widely used in paper cutting, printing, packaging and some electronic fields.Take metal sheet longitudinal cutting as example, it generally uses a pair of upper and lower disk cutter for rolling-shearing process. In the cutting process, the upper and lower disk cutter to maintain the level in the axial gap and radial transfer volume, driven by the rotation of the sheet metal disc cutter is equal to the circumferential velocity cutting discs and gradually into the upper and lower circular knife the edge effect zone, sheet metal cutting edge is cutting discs continue to cut and shear deformation until completely separated. By circular knives and down when pressed into the sheet metal cutting discs elastically deformed by the active region, the shear force suffered from scratch increases, when the sheet is in elastic deformation stage; with the rotary disc cutter, cutting edge up and down cutting discs gradually close the sheet by shearing force continues to increase and the elastic limit of the material reached and shear plastic deformation material into shear deformation stage; thereafter, the shear continues to increase until it reaches the ultimate strength of the material, the material into the crack propagation stage.

Although the working temperature of disc cutter is not so high, it still has large contact pressure to the metal plate. So its wear forms mainly include Co-loss wear, fatigue wear, abrasive wear and adhesive wear.

Co-loss wear: The binder phase Co loss partially, so the bonding strength of WC is weakened and isolated, even drops, which causes the strength, toughness and wear resistance decreasing;

Fatigue wear: due to stress concentration, crushing, shearing and friction prone to fatigue alternating stress micro-cracks in the edge region, and extend toward the center of the knife along the side of the disc;

Adhesive wear: disc cutter and the side sheet metal sub-section is greater pressure contact state, the cutting knife in cold welding material portion side disc. The adhesive layer in the process of continuous cycle cutting off, which wear process aggravated.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Three-flute Drill

- Details

- Category: Tungsten Information

- Published on Thursday, 27 October 2016 18:24

Tungsten carbide three-flute drill is also called core drill, which has three symmetrical flutes and mainly used in gray cast iron, ductile iron, malleable iron, aluminum, magnesium alloys and other short-chipping materials core drilling. It has many advantages, such as:

1. The drill bit has better self-centering capability, do not need additional positional hole;

2. It’s suitable for drilling solid workpiece and obtaining high dimensional accuracy and surface quality;

3. It has open groove, compact design and high process reliability;

4. It has high feeding rate and longer service life, which is suitable for harsh working conditions, such as oblique cuts and intermittent drilling.

Compared single-blade, double-edged drill, it has many advantages:

1. High feeding rate: Although is has small chip flutes, it can be good at breaking chips and discharging smoothly in the processing steel after optimization, which has 1.5-2 times higher than double-edged drill in feeding rate;

2. High accuracy: Three-flute drill with 120 ° aliquots edge design to achieve a stable process, during drilling effectively inhibited the aperture change by the vibration generated from the initial processing to the limit during the life of the tool ensures stable aperture;

3. Reduce the hardening process: The amount of feed per rotating and work hardening and work hardening layer is proportional to the depth. When the same amount of feed per revolution, compared with the traditional two-edged drill bit, three-flute drill bit less feed per edge, hardening reduced.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Facing Cutter

- Details

- Category: Tungsten Information

- Published on Thursday, 27 October 2016 18:11

Tungsten carbide facing cutter generally mounted by throw-away carbide tipped blade. The cutter mounted on the machine spindle and the carbide blade pressed against the cutter by the wedge block. It has high cutting efficiency and cutting accuracy, so it plays an important role in mechanical process.

Common face cutter consists of blade seat, support ring, plate cutter, cutter, cutter body, the outer ring, pin, inner hexagon fastening screws. The blade can be coupled with the seat by bolts, and also processed into a whole, which depends on the cutting force of face cutter. There are many grooves around the cutter, and each of them has an inner and outer groove. And it has threaded hole on the groove accordingly for screw installing and clamping the blade. According to the turning direction of engaged gear and cutter, the teeth arranged in accordance with certain rules.

Main Parameter

|

Number |

Parameters |

Sign |

|

1 |

Number of teeth group |

Z0 |

|

2 |

Cutter radius |

R0 |

|

3 |

Normal max. and min. modulus |

Mnmax、Mnmin |

|

4 |

Cross-section length and width |

H、B |

|

5 |

Max. profile angle |

αmax |

|

6 |

Base radius |

Rb |

|

7 |

Cutter point width |

Wb |

|

8 |

Cutter point height |

Wh |

|

9 |

Cutter edge radius |

Re |

|

10 |

Cutter point radius |

Rok |

|

11 |

Tilt angle, rake angle, clearance angle, lateral angle |

ηb、λ、τ、τ’ |

|

12 |

Main and assistant tooth profile angle |

αok、α’ ok |

|

13 |

Tip and bottom height |

WH |

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Ball-end Cutter

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 October 2016 18:33

Tungsten carbide ball-end cutter is also called R-shaped cutter, usually mounted on miller for milling die steel, cast iron, carbon steel, alloy steel, tool steel, general iron and other materials. It has perfect cutting performance at high temperature. There are some advantages of tungsten carbide ball-end cutter:

1. Stable processing and high surface fineness. When using ball-end mill for processing, the cutting angle is changing continuously, almost no sudden changes;

2. Less consumption, high machining precision, it is the ideal tool for curve surface semi-finishing and finishing (The space of semi-finishing is generally twice longer than the finishing space);

3. Reduce the cutting radius, cutting linear velocity and improve the torque, which is beneficial for spindle motor running smoothly.

However, we should notice that when we are using tungsten carbide ball-end cutter:

1. Avoid using the nose of tool to fabricate the workpiece: Because the linear velocity of the nose of ball-end is zero. In other words, there is milling instead of cutting in this area, which coolant can not add into the cutting area and the cutting heat can not be effectively dispersed;

2. The beat way to machine the straight wall is contour shape processing, it should be noticed that avoid the ball-end process along the straight wall down;

3. Pay attention to the deep groove processing: The tool is easy to sink completely, due to the relatively small chip flutes ball head in the process to increase the viscosity of the material (such as copper), it will be broken easily at high feed speed.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Gear

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 October 2016 18:21

Tungsten carbide gear has better performance in hardness, toughness and wears resistance than other gear materials, so it can effectively ensure the working stability and extend the service life. Generally, tungsten carbide gear is composed of teeth, groove, normal plane, addendum circle, tooth root circle, the base circle and pitch circle.

Teeth: For engaging the convex portion, the raised portions generally radially aligned mating contact of teeth on each gear, the gear can operate in constant engagement;

Groove: The space between two teeth, the end surface is cylindrical or cylindrical worm gear, or a plane perpendicular to the axis of the worm gear;

End surface: The surface two ends of the gear;

Normal plane: Perpendicular to the plane of the tooth line;

Addendum circle: The circle top of the teeth;

Tooth root circle: The circle of the bottom;

The base circle: The circle forming involute, rolling only;

Pitch circle: The base circle of the end face of the gear geometry calculation.

In addition, tungsten carbide gear can be divided by the shape, the profile, the surface and the manufacturing process.

The profile: It includes tooth outline, pressure angle, tooth height. Involute gear relatively easy to manufacture, so the involute gear is absolute majority in the use of modern gear, and less cycloid gear and circular gear applications (straight, helical, herringbone, curved);

The shape: Cylindrical gear, bevel gear, non circular gear, worms;

The surface: The internal gear and the external gear;

The manufacturing process: Casting gear, cutting gear, rolling gear and sintering gear.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com