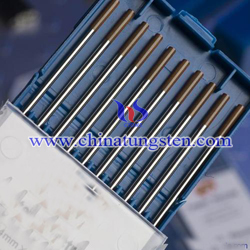

Tungsten Electrodes For Tungsten Inert Gas Welding(TIG)

- Details

- Category: Tungsten Information

- Published on Monday, 31 October 2016 17:57

Tungsten electrode commonly used in tungsten inert gas welding (TIG) includes thorium tungsten electrode, cerium tungsten electrode, lanthanum tungsten electrode, zirconium tungsten electrode, yttrium tungsten electrode, composite tungsten electrode and pure tungsten electrode. Different tungsten electrode has different characteristics, the user can choose according to the requirements. The commonelectrode diameter and length is generally φ0.5-50mm, length: 150mm, 175mm and 178mm. The following will introduce the main features of TIG used tungsten electrode series.

Cerium tungsten electrode: Cerium tungsten electrode is kind of green product, whichdoes not have radioactive contamination. In the case of very small current it can arceasily and the arc current is also less than other tungsten electrode. In the low-current DC conditions, cerium tungsten electrode is more suitable than other tungsten electrodes, which can be used for small pipes and small parts of the welding.

Thorium tungsten electrode: Thorium tungsten electrode is the most widely used electrode among tungsten electrode series, due to its excellent overall performance,which can withstand the overload current. However, currently thorium tungsten electrode is subject to certain restrictions, because it has a slight radioactive contamination, so the user commonly used cerium tungsten electrode and lanthanum tungsten electrode instead of thorium tungsten electrode.

Lanthanum tungsten electrode: lanthanum tungsten electrode has good welding performance and its conductive property is closest to 2% thorium tungsten electrode,which does not have radioactive contamination. In the welding process, the user does not need to change any welding procedure can be quickly and easily to replacethorium tungsten electrode, so the lanthanum tungsten electrode is the best product toreplace thorium tungsten electrode. It is mainly used for DC welding, but can also be used in AC welding, and performed well.

Zirconium tungsten electrode: Zirconium tungsten electrode in the AC has stableperformance. In the welding process, the welding point can be maintained spherical, and the arc is stable. In the high load conditions, the arc is also stable, which is better than other types of tungsten electrodes. In addition, it also has good corrosion resistance property, so it is suitable for magnesium and its alloys AC welding.

Pure tungsten electrode: Pure tungsten electrode is cheap, suitable for alternating current, for magnesium, aluminum and its alloys.

Yttrium tungsten electrode: Yttrium tungsten electrode during welding the arc isslender, large degree of compression, and especially in the large current has maximumpenetration, mainly for military and aerospace industries.

Composite electrode: In the tungsten substrate added two or more rare earth oxides, the additives complement each other, so it has better overall performance and welding performance is better than thorium tungsten electrode.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com