Tungsten Trioxide Nanowire Gas Sensor

- Details

- Category: Tungsten Information

- Published on Thursday, 28 July 2016 17:48

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Nozzle Types

- Details

- Category: Tungsten Information

- Published on Thursday, 28 July 2016 16:37

Tungsten carbide nozzle is a kind of device that composed of the hard phase WC and the binder phase Co, and through a closed cavity or conduit, and out of controlled substances or special direction of gas flow and accelerate. Its hardness can reach 90HRA, tensile strength can reach 2300N/mm and it has the highest competitive price among the nozzle materials due to its good performance in wear and corrosion resistance. At present, tungsten carbide nozzle has been widely used in blasting and shot peening equipment, which can effectively ensure the related products can be used in best atmosphere and abrasives for a long time.

Tungsten carbide nozzle has many types, according to the shape of the nozzle hole (airflow pattern), it can be divided into straight hole, mound hole and restricted hole. The common straight hole has internal air flow in a stream, live or work to form a sealed-type airflow pattern, is often used in some of the more simple, small cleaning work, such as cleaning and welding molded parts, cleaning the house, handrails, stairs, stone carving and so on. Besides, tungsten carbide straight hole nozzle also includes hollow cone nozzles, solid cone nozzles, nozzle square, rectangular nozzles, oval nozzle, fan nozzle, column flow (DC) nozzles, two-fluid nozzle, multi-fluid nozzle and so on. Mounted nozzle can form a relative full flow mode for a given polishing rate of pressure increase up to 100%, compared to the long mound-like nozzle straight bore nozzle in the case of 40% less abrasive consumption may increase 40% in productivity. Venturi nozzle is the best choice for large airflow surface to improve the efficiency. Nozzle with wide throat is also called as wide-angle nozzle, which can be specifically divided into large droplets and small droplets nozzle. It has a large export and a big difference out of the hole when the hose matches the same size, its productivity can be improved by nearly 15% smaller than conventional nozzle throat. In addition, according to different classification methods, tungsten carbide nozzle also has many types, such as petrochemical nozzles, nozzle agriculture, textile nozzle, paper nozzles, nozzle printing, environmental protection (desulfurization, denitrification, denitrification, dust, etc.) nozzle, spray nozzle, steel nozzle metallurgy, electronics nozzles and so on by the applications.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Button — Rockwell Hardness Testing

- Details

- Category: Tungsten Information

- Published on Thursday, 28 July 2016 16:27

At present, there are several indentation hardness tests widely used, such as Rockwell hardness, Brinell hardness (HB), Vickers hardness (HV), Vickers hardness and so on. The biggest difference between Brinell hardness (HB) and Rockwell hardness is the material of indenter ball that Brinell hardness uses steel ball, Rockwell hardness uses diamond. So HB test standards are generally used in the steel before the material is relatively soft, such as when non-ferrous metals, heat treatment or after annealing; Vickers hardness is suitable for the test of large workpiece, deeper surface layer and thin plate; Rockwell hardness has been widely used in tungsten carbide button hardness testing.

Rockwell has no unit, which is a non-mechanical property of dimensionless pointers, the most common hardness scales have A, B, C three kinds, usually referred to as HRA, HRB, HRC. The hardness testing method of tungsten carbide button uses Rockwell hardness of HRA. Its initial pressure used was 98.07N (co 10kgf), using an apex angle of 120 ° diamond cone diamond indenter or ball diameter ball 1.59, 3.18mm then pressurized to 588.4N (co 60kgf), according to the final pressure mark depth to calculate hardness value. HRA measurement range is 20-88 HRA, in terms of the relationship between them is: 27HRA≈30HRB, 60HRA≈100HRB≈20HRC, 85.6HRA≈68HRC.

During the measurement, usually do not take the first value, but after taking the average of the three tests. The position of each measurement point distance should be more than 5mm, the error generally within 0.3HRA, the range expressed in the form beyond 0.3HRA. With the refinement of the raw material and the optimization of the manufacturing process, some carbide materials have reached 93-94 HRA, 20-88HRA beyond the measuring range, the project exceeded the highest HRA measurement range has become a norm. In addition, HRA ruler can be used for distinguishing the soft steel and hard steel, if the value is less than 60 HRB hardness can use HRB scale, when the hardness value is higher than 60HRA can use HRC ruler.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

National Standard for Tungsten Heater——Packing and Transportation

- Details

- Category: Tungsten Information

- Published on Thursday, 28 July 2016 11:22

In order to make products more standardized, National Standard GB11063-1996 of China has made the following clearly defined for tungsten heater labeling, packaging, storage, transportation and quality certificates.

1. The packing of the products should comply with 100 ~ 500pcs or 1 ~ 2kg in a packing box. The box should be sturdy, sealed, moisture, along with product certification. And the certificate should be indicated: name of the product name and trademark, batch number, type and size, quantity and weight, date of manufacture, inspectors mark, national standards number and the name of manufacturer. Product certification or product qualification is the process of certifying that a certain product has passed performance tests and quality assurancetests, and meets qualification criteria stipulated in contracts, regulations, or specifications (typically called "certification schemes" in the product certification industry). Most product certification bodies (or product certifiers) are accredited to ISO/IEC Guide 65:1996, an international standard for ensuring competence in those organizations performing product certifications.

2. Each batch of goods should be accompanied by a certificate of quality. Product quality certificate (document) is used commonly abroad. It not only indicates the product type, size, batch number and inspection personal, it also generally indicates raw material specifications, performance parameters. And furthermore, this certificate provides on key performance indicators test reports or test results and other information. Sometimes it also has the major calculation methods and steps. Therefore, the quality certificate is more credible.

3. The external packaging of wolfram heater must be sturdy or moisture-proof cartons or wooden box, containing a certificate of quality inside.

4. After a packing, products should be stored in a dry (relative humidity is lower than 65%) indoors without any acid and alkaline atmosphere.

5. Outer packing box should be marked "DON’T THROW," "KEEP DRY" and other warnings, and during the transport, the products should be avoided corroded by rain and snow.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

National Standard for Tungsten Heater——Detection Rules

- Details

- Category: Tungsten Information

- Published on Thursday, 28 July 2016 11:17

Before shipping and sale, tungsten heater and other products need to be passed rigorous testing, so that it can guarantee the quality level of trading market in China.

Before shipping and sale, tungsten heater and other products need to be passed rigorous testing, so that it can guarantee the quality level of trading market in China.

According to the National Standard SJT 11063-1996 of tungsten heater, the detection rules include the following five details.

1. The product needs to be examined by quality inspection department of the supplier to ensure that products meet national standards, and fill in the relevant quality certificate. The product quality inspection contains the testing of raw materials, product performance, and product life time as well as product destructive performance.

2. The buyer should check and accept the products in accordance with National Standards within three months of the day that they receive the goods. If the results of acceptance test cannot meet national standards, and the products still unqualified again after the testing by the buyer and the supplier, then this batch is unqualified.

3. According to the first article of technical requirements of the National Standard, operators need to pick one sample at random for chemical analysis. If it is failure unqualified, operators should make a double sampling inspection, if it still unqualified, then it is unqualified.

4. The trademark, type and size of each batch of wolfram heater should be the same. Sampling is to randomly select some quantities (samples) from a batch of products for inspection.

5. According to the technical requirements of the National Standard SJT 11063-1996, operators should pick 50 from 500 ~ 1000 wolfram heater at a random to test their life time, size and surface quality, if there are five which are unqualified, operators should repeat sampling, if there are still five unqualified, then it is determined unqualified.

In order to make tungsten market order better, buyers and sellers should be strict compliance with National Standards of production.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3-Based Ozone Gas Sensor

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 July 2016 17:13

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide DTH Drill Debris Removal System

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 July 2016 15:01

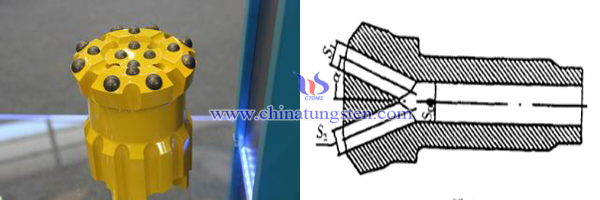

Tungsten carbide DTH drill is composed of steel base, shank and participation nylon tube, tungsten carbide buttons and debris removing system. In the high-frequency impact and continuous scrap of tungsten carbide buttons, it will produce some small debris. If the debris piles up, the wear of buttons will be aggravated and has a bad effect on the service life and the drilling efficiency. So the debris removal system of tungsten carbide DTH drill is significant, which consists of tail hole of drill, top blow hole and the debris removal groove. The top blow hole and the tail hole have staggered structure, design on the top side of the hole location, number and size of the diameter of a hair spray angle holes, need to consider the size of the drill diameter, working pressure, oxygen consumption and tail hole diameter and other factors, the top surface of the hole and the various elements of the hair there is a certain relationship of matches. This structure is equivalent to drill fitted with a tail gas unit, help to make up for the energy and high-pressure air pressure loss in the pipe during operation, the high pressure high speed airflow blown from the hole, which will help drain slag debris.

The injection angle of the blow hole is the included angle of the axis of the injection hole and the center axis, which increases with the increasing pressure. The experiment shows that the higher working pressure, high-pressure air and high-pressure air is blown rock debris or cuttings cutting surface moving ever closer to the rock, rock dust or debris promptly blow hole bottom, spray angle values are generally larger. If high pressure, spray angle is small, the dust were blowing at high pressure gas flow through the bottom of the hole reflected the majority of dust affixed to the surface of the steel drill bit head run, badly worn, bare and likely to cause the intermediate button fracture, drill early failure, reduce the service life of the drill. In addition, the depth of the debris groove chooses according to the working pressure, the rock hardness, higher working pressure or higher the hardness of rock powder discharge groove depth can be relatively reduced.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide DTH Drill Structure

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 July 2016 15:00

With the development of blasting and mining technology, tungsten carbide DTH has high hardness, high strength and excellent wear and corrosion resistance, which has been widely used in the related fields. But the conditions has become more and more complex and there are many uncontrollability and unpredictability, tungsten carbide DTH drill easily appears different kinds of damages and greatly has an effect on the service life of the drill. Through long-term experiments and practice, the researchers found that factors affecting performance and service life of the drill bit working environment, mode of operation, the pressure and the geological structure are loaded in one of the important factors as well as their own material and carbide button drill performance, structure of the drill is also the important factor.

In order to get a more scientific and reasonable design of DTH drilling, we need to know the rock breaking mechanism of carbide DTH drilling. It mainly uses the stress shock wave produced by the impactor to high-frequency impact the rock surface continuously. Under the impact, it will produce radial cracks and resulting in the rotation of the drill pipe squeeze under the crushing action directly to the rock removed. Drilling is the result of the drilling bit high impact and continuous scraping. At the same time, under the action of high-pressure air, the cuttings are crushed continually blow hole outside, so as to achieve the purpose of drilling. Tungsten carbide DTH drill is composed of steel base, shank and participation nylon tube, tungsten carbide buttons and debris removing system. Steel base plays an important role in delivering stress shock wave and torque, maintaining and fixing the buttons. While tungsten carbide buttons are charged with the high frequency stress waves from the impactor and passed directly to the rock face for cutting process. In addition, it should be noticed that the relationship among the various elements during the process, especially the clearance fit.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

National Standard for Tungsten Heater——E, M Type

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 July 2016 11:31

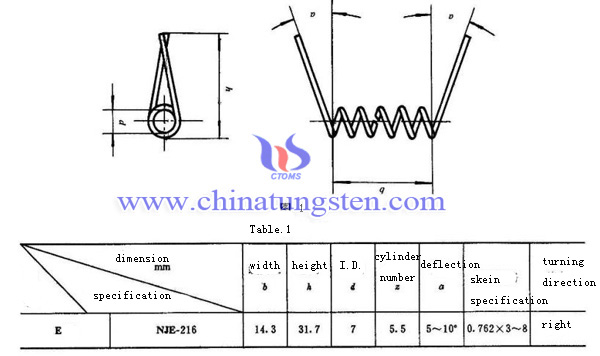

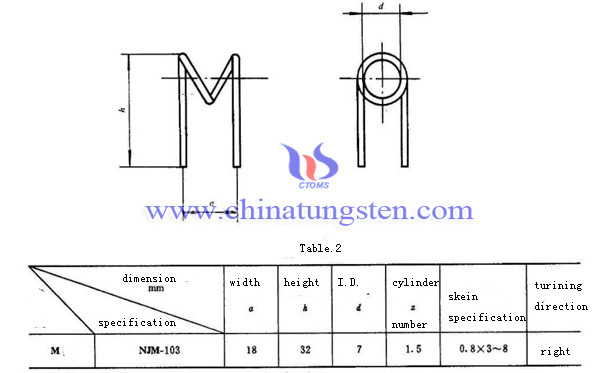

Tungsten heater made of tungsten wire, features high melting point and high corrosion resistance, mainly applied for vacuum metalizing, such as aluminizing scope, chrome scope, mirrors, plastics and heater elements for decoration articles. According to the national standard for tungsten heater, except A, B, C, V, D1 and D2 six types, the types of the wolfram heater also including E type and M type.

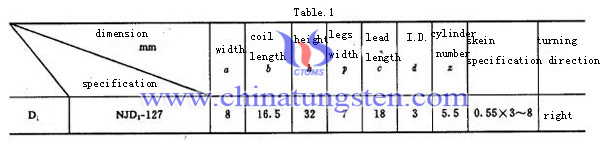

It can be seen from Figure 1 and Table 1, E-type tungsten heater’s legs are longer, and splay outward.

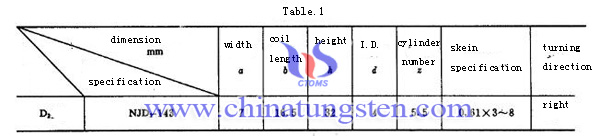

From Figure 2 and Table 2, profile of M type tungsten heater is in the shape of the capital letter "M", and rotation is right.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

National Standard for Tungsten Heater——V, D1, D2 Type

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 July 2016 11:28

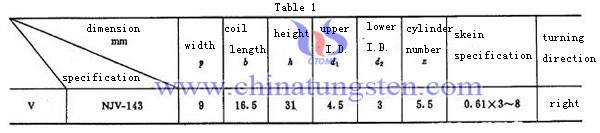

Tungsten heater, also known as tungsten coil, which can be stranded into single or multi wires according to the samples or drawings of customers. Pure wire and doped wire are both available. After the special heat treating, it has the strong corrosion resistance and elevated temperature property with a long life time,which is widely used in thin film technology.

According to the national standard for tungsten heater, except A, B, C three types, the types of the wolfram heater also including V type, D1 type and D2 type.

The shape of V type, D1 type and D2 type are similar to each other, their rotation direction are right,the main difference is the width between the legs. Their shapes are similar with the english lowercase letter "n". From the following three picture, people can see clear distinctions among 3 types.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com