Tungsten Heater for Aluminizing - Vacuum Conditions

- Details

- Category: Tungsten Information

- Published on Monday, 01 August 2016 15:58

Tungsten heater for vacuum evaporation means that evaporated material was heated to a considerably high temperature in vacuum to reach a vaporized state, then the vaporized material would deposit on the substrate surface and make a thin film, this process is called vapor deposition. In order to ensure the material can be evaporated effectively on the phosphor screen, the mean free path must be longer than the distance between evaporation source and the substrate. Therefore, the evaporation process must be carried out in a certain vapor pressure. Aluminum is malleable material, which is often made into a rod, sheet, foil, powder, ribbon and filamentous. It can form an oxidation film to prevent the metal from oxidizing in a wet environment.

Tungsten heater for vacuum evaporation means that evaporated material was heated to a considerably high temperature in vacuum to reach a vaporized state, then the vaporized material would deposit on the substrate surface and make a thin film, this process is called vapor deposition. In order to ensure the material can be evaporated effectively on the phosphor screen, the mean free path must be longer than the distance between evaporation source and the substrate. Therefore, the evaporation process must be carried out in a certain vapor pressure. Aluminum is malleable material, which is often made into a rod, sheet, foil, powder, ribbon and filamentous. It can form an oxidation film to prevent the metal from oxidizing in a wet environment.

First of all, open coating machines, vacuum vacuum degree should reach 5 × 10-5 Torr or more, and then pre-melt the evaporation material. Evaporation distance is 6.5 cm, deposition materials area diameter is 5.5 cm. Operators can add a bell and a support plate. The area of the film made by this method is small and it can only plate a fluorescent screen. Quality of aluminum film is better by this method, but efficiency is not good, a screen can only be plated for one time, and the film is uneven. Due to the distance of evaporation is short and the screen cannot withstand high temperatures, it can only evaporate quickly, then the area of the film is small.

Aluminum is evaporated directly in the vacuum of 2 × 10-1 Torr. Evaporation materials is the five aluminum, each length is 0.8 cm, and the total length of tungsten wire heater is 8.5 cm with a diameter of 0.5 mm, when a vacuum evaporation coating chamber reaches 2 × 10-1E, pre-melting the aluminum wire firstly, then add the air into chamber again, the degree of vacuum is adjusted to 2 × 10-1E. These vacuum conditions can be used to aluminizing, but the area of the film is also small.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Heater for Aluminizing – Large Area Film

- Details

- Category: Tungsten Information

- Published on Monday, 01 August 2016 15:56

Generally speaking, vacuum evaporation rate, uniformity, film thickness and vacuum evaporation are related to tungsten heater element shapes, sizes. The distance of the evaporation source and the workpiece is determined by vacuum evaporation degree and the required film thickness and other factors. When the evaporation distance is 6.5 cm, because of evaporation distance is short, the film will be uneven, and each screen can only be plated for one time, the working efficiency is not good enough, and it cannot meet the requirements of large-area screen. So the original 6.5 cm evaporation distance should be increased to 28 cm, and the diameter would be able to reach 26.5 cm, the evaporation of aluminum should be increased 6 points, the distance between each point can be controlled at 0.5 cm, each length of aluminum wire is 1.8 cm, diameter of tungsten heater is 0.7 mm with a total length of 15 cm. This can obtain large-area and uniformity film.

Generally speaking, vacuum evaporation rate, uniformity, film thickness and vacuum evaporation are related to tungsten heater element shapes, sizes. The distance of the evaporation source and the workpiece is determined by vacuum evaporation degree and the required film thickness and other factors. When the evaporation distance is 6.5 cm, because of evaporation distance is short, the film will be uneven, and each screen can only be plated for one time, the working efficiency is not good enough, and it cannot meet the requirements of large-area screen. So the original 6.5 cm evaporation distance should be increased to 28 cm, and the diameter would be able to reach 26.5 cm, the evaporation of aluminum should be increased 6 points, the distance between each point can be controlled at 0.5 cm, each length of aluminum wire is 1.8 cm, diameter of tungsten heater is 0.7 mm with a total length of 15 cm. This can obtain large-area and uniformity film.

The thickness of the film can be controlled and measured with a film thickness measuring instrument and optical thin film controller. Both instruments can be used to measure the thickness of the film, but the measurement of optical thin film controller is more accurate. According to the test of tube, it is better to use a 50% transmissivity, which does not affect the incident electron energy, and it will not affect the resolution of the phosphor screen.

In addition, the coating vacuum chamber should be kept clean, after plating, it should be cleaned by absolute ethyl alcohol. Each parts of vacuum chamber should be ready for the next time. Operators should pay attention to the degree of vacuum coating whether it is stable or not. And select the appropriate evaporation rate when degree of vacuum reaches the requirement, the rate should be quick, which can form a well-distributed film with high quality.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Hydrothermal Method to Prepare Tungsten Trioxide Nanowire

- Details

- Category: Tungsten Information

- Published on Friday, 29 July 2016 16:55

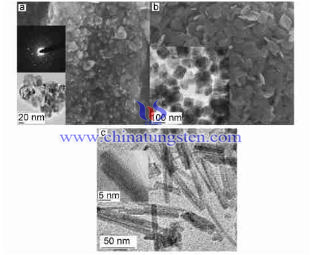

In recent years, the research of various tungsten trioxides low-dimensional structures is ongoing, like one-dimensional nanowire and nanotubes, two-dimensional nanosheet ect.. Due to their higher specific surface area, and the size at certain directions and the Debye length for the particular comparable; compared with micron or films structural, those tungsten oxide with low-dimensional nanostructures have a better performance, particularly in enhancing gas sensitivity, shortening response time and reducing reaction temperature and other properties of gas sensors, and also to improve the optical properties, such as it shows a huge advantage at the properties of thermochromic, photochromic, electrochromic, photochromic and so on.

In recent years, the research of various tungsten trioxides low-dimensional structures is ongoing, like one-dimensional nanowire and nanotubes, two-dimensional nanosheet ect.. Due to their higher specific surface area, and the size at certain directions and the Debye length for the particular comparable; compared with micron or films structural, those tungsten oxide with low-dimensional nanostructures have a better performance, particularly in enhancing gas sensitivity, shortening response time and reducing reaction temperature and other properties of gas sensors, and also to improve the optical properties, such as it shows a huge advantage at the properties of thermochromic, photochromic, electrochromic, photochromic and so on.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Based NH3 Gas Sensor

- Details

- Category: Tungsten Information

- Published on Friday, 29 July 2016 16:52

Ammonia (NH3) is a colorless gas with a strong pungent odor, which can be easily liquefied into the colorless liquid ammonia, something that can be used as a refrigerant. Ammonia gas is an important chemical product which can be used in making liquid nitrogen, aqueous ammonia, nitrate, ammonium salt, and amines ect.; it has a strong reducibility and can be used as catalytic denitration reducing agent; in addition, under the exiting of catalyst, it can be oxidized to nitric oxide. Ammonia can be directly prepared by the synthesis of nitrogen and hydrogen gas; with its strong reducibility it will burn the skin, eyes, and respiratory mucosa, when a man excessively inhaled the ammonia, lung swelling will be caused or even death.

Ammonia (NH3) is a colorless gas with a strong pungent odor, which can be easily liquefied into the colorless liquid ammonia, something that can be used as a refrigerant. Ammonia gas is an important chemical product which can be used in making liquid nitrogen, aqueous ammonia, nitrate, ammonium salt, and amines ect.; it has a strong reducibility and can be used as catalytic denitration reducing agent; in addition, under the exiting of catalyst, it can be oxidized to nitric oxide. Ammonia can be directly prepared by the synthesis of nitrogen and hydrogen gas; with its strong reducibility it will burn the skin, eyes, and respiratory mucosa, when a man excessively inhaled the ammonia, lung swelling will be caused or even death.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Cylindrical Nozzle and Fan-shaped Nozzle

- Details

- Category: Tungsten Information

- Published on Friday, 29 July 2016 14:41

Tungsten carbide cylindrical nozzle is a kind of new nozzle that based on the conventional nozzle and sprays advantages and reforms the internal structure. It can not only spray the substantial column jet, but also can form the fan-shaped covering, which plays an important role in fireproof equipment. Furthermore, in the cement cooler cooling systems often use this type of nozzle. The reasonable structural optimization and precision processing technology can reduce the atomization pressure, improve the effect and better for saving energy. In 0.3MPa can be atomized droplets having a diameter of 60-80 microns, to ensure that the droplets in the shortest possible time to fully evaporate, avoid hanging wall phenomenon. In order to clean nozzle conveniently, new type cylindrical nozzle improve the block and higher maintenance costs of conventional pressure nozzle by changing the internal structure.

Tungsten carbide fan-shaped nozzle is a kind of nozzle that the diversion is refined and processed so the spray plane form a uniform and have a high impact sector. It has larger spraying channel and relatively smooth, which greatly reduce the clogging. Due to the gravity, it will appear edge effect that when the fan-shaped spray produce cross-sectional tapering edge of the spray particles are small and uniform spray particle size plurality of nozzles are arranged in the middle, you need to have the overlapping portion of 25% to 30%, so that the entire arrange uniformly in the direction. In addition, using a variety of fan-shaped spray angle of the spray flow, droplet size medium connection using the modular units can be convenient for installing, replacing and filters can be installed for cleaning easily. At present, tungsten carbide fan-shaped nozzle has a broad application prospect in chemical cleaning of dirt, metal processing, oil stains, spray coating, cleaning, cooling and so on.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Nozzle Ceramic Nozzle Comparison

- Details

- Category: Tungsten Information

- Published on Friday, 29 July 2016 14:39

In the early days, the major material for nozzle is iron, but it has low hardness, poor performance in wear and corrosion resistance and the service life is relatively short. Except the iron, hardened steel and stainless steel are also two kinds of more common metal nozzle materials. They have simple manufacturing process, low cost, which is suitable for some cleaning work, except the large-scale operations. Until the late 1930s, with the abrasive jet technology and the rapid development of materials science and technology to the production of carbide lined nozzles was only developed.

Compared with iron nozzle, tungsten carbide nozzle has more complex manufacturing process, higher cost, but it has remarkable improvements in the hardness, the strength, the wear and corrosion resistance and the service life. Especially in erosion rate, tungsten carbide has better performance in the erosion resistance. But due to the high hardness, low toughness, brittle, difficult to be fabricated, which is not suitable for the manufacture of nozzle with complex structure. In practical, tungsten carbide usually to be machined into ring or block to mount on the parts of easily wore, so the wear and corrosion resistance of the parts can be improved. With the emergence of high-performance ceramic materials, nozzle performance has been further improved. High-performance ceramic material has better heat resistance and fracture toughness than tungsten carbide materials, which has be widely used in many engineering, such as cutting tools, bearing parts, engine components and metallurgy, coal, chemical industry, abrasion and corrosion-resistant parts. The erosion resistance and service life of the ceramic nozzle is also far superior to ordinary metal and carbide nozzles. Especially when using quartz sand, slag and metal abrasives, abrasion resistance of the ceramic nozzle several times higher than carbide, but it is typical of a brittle material, easy to crack under the impact of the materials or peel off, and therefore not suitable for high-impact occasions using.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Influencing Factors of Tungsten Electrode Arc Performance

- Details

- Category: Tungsten Information

- Published on Friday, 29 July 2016 14:18

The arc performance refers to arc ignition capacity, arc stability, arc pressure, temperature distribution characteristic and arc compressibility and directivity, namely static and dynamic characteristics of the arc. During welding, the physical and chemical properties, mechanical properties, chemical composition and structure of electrode will have some effect on the arc performance and to understand these influencing factors on the arc performance can improve electrode’s welding performance.

Chemical Composition:

Doped with rare earth oxide with different types and different contents, the arc performance of tungsten electrode is also different. Generally tungsten electrode doped with three different rare earth oxides has better arc performance than electrode which doped with two different rare earth oxides and doped with single rare earth oxide. In addition, the distribution and temperature properties of rare earth oxides will have a certain impact on the arc performance and arc stability. The electrode which is uniformly distribution and slower evaporation rate has better arc performance.

Organizational Structure:

Integrity and uniformity of the tungsten electrode structure has a direct effect on the arc performance. If there is splitting, delamination, micro-cracks, voids, inclusions or severely uneven grain structure in the electrode inner, it will affect electrode’s arc performance, so during the arc process will cause arc breaking, arc blasting, or drifting, but also will affect electrode’s thermal conductivity and electrical conductivity, so that the electrode locally overheated, melt, deformation, worsen electrode performance.

Physical and Mechanical Properties

the tungsten electrode, having high melting point, high boiling point, low vapor pressure, good thermal and electrical conductivity, high temperature strength, good creep resistance and high recrystallization temperature, has better arc performance.

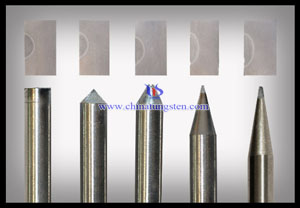

Shapes

Tungsten electrode can be made in different shapes depending on the application. The shape of the electrode, especially the shape and angle of the end portion has significant influence on the arc performance. The flat end requires higher arc voltage and current and the tip portion requires lower voltage and current. Smaller angle is good for arcing, but the deformation resistance is poor, thus determining the angle of the electrode end portion depends on the welding conditions.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode Chemical Composition Affected Arc Performance

- Details

- Category: Tungsten Information

- Published on Friday, 29 July 2016 14:15

Pure tungsten electrode has higher electron work function, which is not good for electron current emission, so that the electrode can not work under high load conditions. In order to enhance electrode’s welding performance and to increase applications fields, the manufacturers developed various types of tungsten electrodes, including thorium tungsten electrode, zirconium tungsten electrode, lanthanum tungsten electrode and yttrium tungsten electrode and so on. According to electric current density formula Je = AT2exp (-eØ / kT) (A is a constant, k is Boltzmann's constant, T is the temperature of the cathode, e is the electronic charge, Ø is work function) can know, when the temperature is the same, the smaller the value eØ, the greater the value Je. Therefore, in order to reduce eØ, manufacturers will add a small amount of rare earth oxide in the tungsten electrode material. Doped with different amount of rare earth oxides, the electrode has specific Je value, namely having specific arc performance.

In the same rare earth tungsten electrode, the electrode having high rare earth oxide content has better arc performance. In addition, uniformity distribution and diffusion and migration behavior of rare earth oxides also affect electrodes’ arc performance. The arc performance deterioration is mainly due to the rare earth oxides evaporation and decomposition causing electron emission performance degradation. Form this we can know tungsten electrode chemical composition’s type, content, distribution and temperature characteristics determines arc performance.

During the welding process, the electrode will appear Rim phenomenon, having nodules appeared in the tip of electrode and this phenomenon can well explain the impact of the chemical composition on electrode’s arc performance. Rim phenomenon occurs mainly because the rare earth oxide content of the electrode surface is higher than the central portion, thus facilitating to arc in a short time, but in the arc process will mix a small amount of O2 or welding parameters adjusted overload in the short term are likely to experience Rim phenomenon. This is the result of the tungsten electrode chemical composition changes at high temperatures. This phenomenon is in favor of arcing at the beginning, but after a long time will lead to the concentration of rare earth oxide on surface layer depleted, thereby reducing the arc performance.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

National Standard for Tungsten Heater——Life Time Test Requirements

- Details

- Category: Tungsten Information

- Published on Friday, 29 July 2016 11:06

Oxidation of tungsten heater refers to tungsten wire react with oxygen in the air, it could lead to breakage, thus shortening its life. Tungsten has a high melting point, high resistance, high strength, low vapor pressure, which is suitable for the heating element. The film material (aluminum, chromium, indium, etc.) will evaporate under vacuum plating machines, high vacuum, the heating element, so that the film becomes shiny and beautiful.

Generally speaking, the life time of the tungsten heater is more than 300 times, but if done incorrectly, wolfram heater will change color into yellow, and then the central section of the wolfram heater will produce irregular cracks which cannot be used in the normal evaporation process of aluminum. A good control of wolfram heater life time can greatly reduce the cost of producing, it also can ensure the quality of the subsequent deposition to some extent.

According to the National Standard SJT 11063-1996, life time test requirements of wolfram heater are divided into three kinds on the basis of different test equipment.

I: Test equipment: No. 379 493 vacuum equipment of ULVAC JAPAN LTD:

1. The Degree of Vacuum: 1.33 × 10-2Pa.

2. Current: 60 ~ 100A.

3. Voltage: preheat 3.5 ~ 5.0V, evaporation 5.5 ~ 8.0V.

4. Evaporation Time: preheat 18 ~ 21s, evaporate 16 ~ 25s.

5. The Inserted amount of Aluminum: 100 ~ 120mg.

6. Aluminum Wire Purity: 99.99%.

II: Test equipment: DMW-1350 type rotary vacuum coating machine:

1. The Degree of Vacuum: 1.33 × 10-2Pa.

2. Current: 90A.

3. Voltage: 8.0V.

4. Evaporation Time: 1 ~ 1.5min.

5. The Inserted amount of Aluminum: 0.4 ~ 0.7g.

6. Aluminum Wire Purity: 99.45% ~ 99.99%.

III: Test equipment: DM-670F-type vacuum coating machine:

1. The Degree of Vacuum: ≥6.65 × 10-2Pa.

2. Evaporation Time: 0.6 ~ 0.9kA.

3. Evaporated voltage: 120 ~ 170V.

4. Evaporation Time: 1min.

5. The Inserted amount of Aluminum: 0.3 ~ 0.4g.

6. Aluminum Wire Purity: 99.99%.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3-Based Hydrogen Sulfide Gas Sensor

- Details

- Category: Tungsten Information

- Published on Thursday, 28 July 2016 17:52

Hydrogen sulfide, the formula H2S, is an important chemical raw material, a flammable acidic gas under the standard condition with colorless, smelling like rotten eggs at low concentrations, has highly toxic, and its solution in the water is called the hydrogen sulfate. Hydrogen sulfide is a flammable hazardous chemicals, which can be formed to the explosive mixtures with the air; and when it meets with an open fire and high-heat, it will cause combustion and explosion. Even low concentrations of hydrogen sulfide can damage a person's sense of smell; but there is no odor at high concentrations (because the olfactory nerve will be palsied by the high concentration of hydrogen sulfide), so the way to use the nose to detect this gas is fatal. Therefore, the use of certain testing tools and instruments to detect its concentration is very necessary.

Hydrogen sulfide, the formula H2S, is an important chemical raw material, a flammable acidic gas under the standard condition with colorless, smelling like rotten eggs at low concentrations, has highly toxic, and its solution in the water is called the hydrogen sulfate. Hydrogen sulfide is a flammable hazardous chemicals, which can be formed to the explosive mixtures with the air; and when it meets with an open fire and high-heat, it will cause combustion and explosion. Even low concentrations of hydrogen sulfide can damage a person's sense of smell; but there is no odor at high concentrations (because the olfactory nerve will be palsied by the high concentration of hydrogen sulfide), so the way to use the nose to detect this gas is fatal. Therefore, the use of certain testing tools and instruments to detect its concentration is very necessary.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com