Hydrothermal Method to Prepare Tungsten Trioxide Nanowire

- Details

- Category: Tungsten Information

- Published on Friday, 29 July 2016 16:55

In recent years, the research of various tungsten trioxides low-dimensional structures is ongoing, like one-dimensional nanowire and nanotubes, two-dimensional nanosheet ect.. Due to their higher specific surface area, and the size at certain directions and the Debye length for the particular comparable; compared with micron or films structural, those tungsten oxide with low-dimensional nanostructures have a better performance, particularly in enhancing gas sensitivity, shortening response time and reducing reaction temperature and other properties of gas sensors, and also to improve the optical properties, such as it shows a huge advantage at the properties of thermochromic, photochromic, electrochromic, photochromic and so on.

In recent years, the research of various tungsten trioxides low-dimensional structures is ongoing, like one-dimensional nanowire and nanotubes, two-dimensional nanosheet ect.. Due to their higher specific surface area, and the size at certain directions and the Debye length for the particular comparable; compared with micron or films structural, those tungsten oxide with low-dimensional nanostructures have a better performance, particularly in enhancing gas sensitivity, shortening response time and reducing reaction temperature and other properties of gas sensors, and also to improve the optical properties, such as it shows a huge advantage at the properties of thermochromic, photochromic, electrochromic, photochromic and so on.

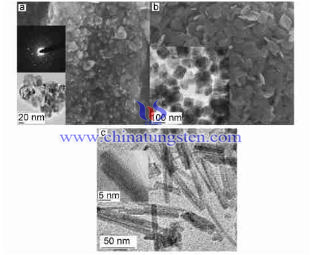

Hydrothermal method is a commonly used method for producing nano-crystalline materials, which has the significant advantage of requiring the simple experimental equipment, low cost, and generally can obtain the crystalline product without requiring high temperature heat treatment, and also can achieve mass production. In addition, the hydrothermal synthesis of confined conditions is conducive to those toxic reaction systems which are harmful to human health, and reduce environmental pollution. This paper introduces the process of hydrothermal method to prepare tungsten trioxide nanowire as following steps:

1. Dissolve an appropriate amount of sodium tungstate in an amount of deionized water to prepare the sodium tungstate solution with the weight ratio of 1.5 ~ 8. 0%, then carry out magnetic stirring in an ice water bath for one hour to form the colorless and transparent sodium tungstate;

2. Slowly drop the appropriate amount of 3M/L hydrochloric acid into the obtained sodium tungstate solution and continue stirring for 1.5 hours to form a pale yellow solution micelle, then centrifuge the micellar solution at a speed of 4000 rpm /min for 20 minute;

3. Uniformly disperse the centrifuged product in an appropriate amount of 11.5M/L of potassium sulfate solution to form a mixed solution, and take 80 ml of the mixed solution to transfer into 100ml of reactor to carry out the hydrothermal reaction at 180~270 ° C for 12~120 hours;

4. The hydrothermal products are dried at 70 °C for 2 hours in the air after they have been repeatedly washed with deionized water and absolute alcohol, then we get the hexagonal tungsten trioxide nanowire with high specific surface area and can remain stable at the temperature of less than 450°C.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com