Explanation of Tungsten Heater for Vacuum Plating——Evaporating Coating

- Details

- Category: Tungsten Information

- Published on Thursday, 21 July 2016 11:53

Chemical coating was first used in the preparation of the optical element surface protective film. Subsequently, in 1817, Fraunhofe in Germany used concentrated sulfuric acid or nitric acid to corrode glass, occasionally got the first antireflection film. Before 1835, there was someone used wet chemical deposition method to make silver mirror film which was the oldest optical thin-film prepared in the world film. Later, people used chemical solution and steam to plat various optical films. In 1950s, except large windowpane antireflection coating applications, the chemical plating solution was gradually replaced by vacuum coating. Physical vacuum coating process vacuum evaporation and sputtering are by far the two main processes for coating industry. In 1935, it was developed a vacuum vapor deposition of a single layer antireflection coating. Its first application was plating in the spectacle lens after 1945.

Chemical coating was first used in the preparation of the optical element surface protective film. Subsequently, in 1817, Fraunhofe in Germany used concentrated sulfuric acid or nitric acid to corrode glass, occasionally got the first antireflection film. Before 1835, there was someone used wet chemical deposition method to make silver mirror film which was the oldest optical thin-film prepared in the world film. Later, people used chemical solution and steam to plat various optical films. In 1950s, except large windowpane antireflection coating applications, the chemical plating solution was gradually replaced by vacuum coating. Physical vacuum coating process vacuum evaporation and sputtering are by far the two main processes for coating industry. In 1935, it was developed a vacuum vapor deposition of a single layer antireflection coating. Its first application was plating in the spectacle lens after 1945.

Tungsten heater for vacuum plating in evaporation coating process requires following points:

1. Aluminum should be wrapped on tungsten. If previously molten aluminum in plating coated became spherical and covered tungsten, and then it cannot be used, it needs to be replaced a new tungsten wire.

2. The injection mold parts should be pushed into the vacuum chamber buy car, keeping close contact with the electrodes, jaw clucth should be able to rotate.

3. Use a mechanical pump, Roots pump and diffusion pump to exhaust, when the degree of vacuum pointer reaches 5 × 10-4TORR, deposition can be started.

4. The vapor deposition process: the tungsten wire is heated to 650℃, the aluminum would be molten in tungsten, continue to rise to near 1000℃, the molten aluminum atoms is vaporized to its surface, plated products on a vacuum chamber constantly to be rotating with cage which makes plated surface coated with a uniform layer.

5. The average production cycle of coating is about 30 minutes.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Enhances Pt-Based Catalyst Performance

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 July 2016 17:45

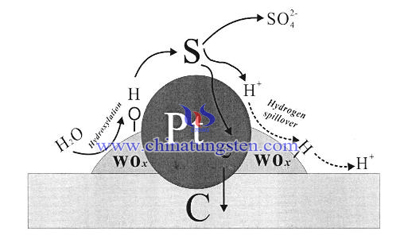

The fuel cell belongs to a green energy technology, while the key material is the important factor which restricts its widely application, which is the catalyst using a large amount of precious metal, with not high activity, and the stability can not meet the application requirements, all these factors restrict its development in terms of cost. Proton exchange membrane fuel cell is concerned a lot due to its high efficiency, safety and environmental and other advantages. Tungsten trioxide and tungsten carbide is relatively stable in a fuel cell environment, also it has synergistic effect with the metal catalyst, and make it the ideal alternative carrier of carbon.

The fuel cell belongs to a green energy technology, while the key material is the important factor which restricts its widely application, which is the catalyst using a large amount of precious metal, with not high activity, and the stability can not meet the application requirements, all these factors restrict its development in terms of cost. Proton exchange membrane fuel cell is concerned a lot due to its high efficiency, safety and environmental and other advantages. Tungsten trioxide and tungsten carbide is relatively stable in a fuel cell environment, also it has synergistic effect with the metal catalyst, and make it the ideal alternative carrier of carbon.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Different WO3 Doping Amount Affects Methanol Oxidation

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 July 2016 17:41

Direct Methanol Fuel Cell (DMFC) belongs to the proton exchange membrane fuel cell (PEMFC), which directly use aqueous or steam methanol as fuel supply source, without the reforming of methanol, gasoline and natural gas for hydrogen generation. Direct methanol fuel cell with the properties of quickly starting at low temperature, clean and environmental protection and sample battery structural ect., have been studied extensively.

Direct Methanol Fuel Cell (DMFC) belongs to the proton exchange membrane fuel cell (PEMFC), which directly use aqueous or steam methanol as fuel supply source, without the reforming of methanol, gasoline and natural gas for hydrogen generation. Direct methanol fuel cell with the properties of quickly starting at low temperature, clean and environmental protection and sample battery structural ect., have been studied extensively.WO3+xPt-H→HxWO3+xPt

HxWO3→xH++xe-+WO3

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Inhibitor Effect on Tungsten Carbide Button

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 July 2016 15:14

Theoretically, the smaller granularity, the hardness is higher; and the fracture strength of materials with the increasing hardness. In order to improve the hardness and the strength of tungsten carbide buttons, we have to optimize the sintering process and add grain growth inhibitor properly to inhibit the growth of grains. The common used inhibitor in the sintering process of tungsten carbide powder include TaC, MoC, Cr3C2, VC, NbC and so on, which can be as a single additive can also be a certain percentage of the composition of compound inhibitor. In addition, some researchers add refractory metal carbides into the Co-rich matrix and the resulting solid solution as the inhibitor. It can remarkably decrease the melting point of the base, Co formed in the liquid phase in a stable metal / non-metallic atomic group, and the presence of the radicals will hinder W, C atoms from one grain to another grain adjacent liquid migration, thereby further reducing the WC grain growth rate.

Rare earth elements can also be used as grain growth inhibitors which also inhibit grain growth and improve the performance of tungsten carbide buttons during sintering. There are many rare earth elements such as Y, La, Nd, Pr, Ce, may also be added in the form of rare earth metal oxides and mixed rare earth. The main role of the rare earth element is:

1. Lively nature, a strong affinity to O, S, N, C and other elements, so tungsten carbide button in these impurity elements form a rare earth compound particle and distributed at the grain boundaries. This also effectively prevents the diffusion of dissolved in liquid Co and WC phases of grain boundary migration suppressed uneven WC grain growth;

2. Purify the grain boundaries and remove the impurities, rare earth elements and impurity elements combine to form a spherical compound of the binder phase dispersion strengthening. In the both mechanisms above, the hardness, the bending strength of tungsten carbide button has been significantly strengthened. At the same time, rare earth elements can effectively reduce the sintering temperature of tungsten carbide button, and better solve the contradiction between controlling grain growth and densification.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Copper / Tungsten Copper Welding Contacts

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 July 2016 16:19

Due to excellent thermal and electrical conductivity, copper / tungsten copper has been widely used in electric motor and electronics fields. Since the electrical contacts manufactured by single pure copper has lower hardness and in the case of heated prone to softening (melting point of copper is low), especially in some high-voltage, high-load switch contacts can not ensure the operation stable. So in order to ensure the electrical contact reliability and durability, the relevant researchers found that copper electrode coated with a layer of tungsten copper can effectively improve the overall properties, such as the density, the hardness, the anti-ablation, the thermal shock resistance, heat dissipation and the service life.

At present, there are many processes to connect copper and copper alloy, such as vacuum brazing, vacuum diffusion welding, vacuum electron beam welding, resistance welding, inert gas welding and friction welding and so on. Here we mainly introduce vacuum brazing and vacuum diffusion welding. In general, vacuum brazing in air and vacuum furnace, the solder and flux sequentially sandwiched between copper and tungsten copper, heated to 780 ℃, held 20min, and cooled; it should be noticed that the controlling the degree of vacuum, pressure welding, soldering temperature and holding time. Viewed from micro structure, vacuum diffusion welding contacts, copper and tungsten-copper-binding capacity is good, the interface is relatively smooth transition. And by brazing process, filler metal substrate with good bond, and the role of the liquid solder and copper tungsten alloy between the copper is not so intense. In terms of resistivity, vacuum brazing contact resistivity lowest close resistivity tungsten copper base material, when brazing in air contacts prone to oxidation, impurities and porosity and other weld defects, uniformity of can not be effectively guaranteed, and so the electrical resistivity is higher.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Tube Hole Processing Problems

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 July 2016 16:17

Tungsten copper tube takes advantage of W powder with high purity, high hardness, high strength and excellent wear resistance and Cu powder with high purity and excellent thermal and electrical conductivity, after isostatic pressing, sintering and high temperature copper infiltration process to obtain high-performance composite materials. It has many advantages, such as good performance in arc breaking, thermal conductivity, electrical conductivity, do not soften at high temperature, high metal removal rate, higher surface finish of processing mold, longer service life, which has been widely used in high-voltage discharging tube and high-temperature components. However, it also due to good wear resistance and heat resistance, which is difficult to process and the wall thickness is generally thinner, strength and stiffness are weak, prone to be broken.

Conventional hole processing is to fine bore the inner hole to meet the requirements of the surface roughness; then fed with standard reamer (six teeth). But after processing by this method, the dimensions, shape and precision of the workpiece are difficult to meet the requirements of the drawing. Even some workpieces has been split, the rate of rejects reach 50%-60%, which because of:

1. In the process of inner hole turning, the turning tool is thinner and has bad performance in rigidity, which is vibrating easily and difficult to achieve the required size reaming process;

2. Reaming performed in semi-enclosed space, the chip is more difficult to discharge, prone to accumulation and the bore surface scratches, some minor chips glued to the edge of the hole wall friction will increase the surface roughness; chips even larger particles surface ablation process seriously;

3. Chip jamming in the slot knife cutting force and cutting temperature increases also accelerated tool wear;

4. Reaming margin greater accumulation of excessive force or reaming chips reaming force likely to cause mutation, when it exceeds the ultimate strength of the material of the bursting of the workpiece occurs.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Explanation of Tungsten Heater for Vacuum Plating——Injection Mold Parts

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 July 2016 10:11

Injection molding machine is called as die cutting machine in injection molding industry. An Injection molding machine, also known as an injection press, is a machine for manufacturing plastic products by the injection process. It consists of two main parts, an injection unit and a clamping unit. Injection molding machines can fasten the molds in either a horizontal or vertical position. The majority of machines are horizontally oriented, but vertical machines are used in some niche applications such as insert molding, allowing the machine to take advantage of gravity. Injection molding machine can form complex shape dense plastic products with the precise size, which is widely used in national defense, electronics, automotive, transportation, building materials, packaging, agriculture, education and health. With the rapid development of the plastics industry today, whether in the number or species, the injection molding machine occupies an important position, and its production accounts for 20%~30% of the total number of plastic molding equipment, thus becoming one of the fastest growing plastic machinery.

Injection molding machine is called as die cutting machine in injection molding industry. An Injection molding machine, also known as an injection press, is a machine for manufacturing plastic products by the injection process. It consists of two main parts, an injection unit and a clamping unit. Injection molding machines can fasten the molds in either a horizontal or vertical position. The majority of machines are horizontally oriented, but vertical machines are used in some niche applications such as insert molding, allowing the machine to take advantage of gravity. Injection molding machine can form complex shape dense plastic products with the precise size, which is widely used in national defense, electronics, automotive, transportation, building materials, packaging, agriculture, education and health. With the rapid development of the plastics industry today, whether in the number or species, the injection molding machine occupies an important position, and its production accounts for 20%~30% of the total number of plastic molding equipment, thus becoming one of the fastest growing plastic machinery.

Tungsten heater for vacuum plating has a high requirement for injection mold parts :

1. Injection mold parts surface must be kept clean and smooth without any oil stain and besmirch.

2. The surface roughness of injection mold parts should be low To the greatest extent.

3. The internal stress of injection mold parts should maximize minimized, and both inside and outside corners should be rounded corner. Use lower injection pressure and the higher mold temperature, and injection speed should be slow.

4. The shape of injection mold parts is conductive to obtain a uniform coating, such as slightly protruding in the middle of a large flat-screen.

5. The wall thickness of injection mold parts should be appropriate, too thin can cause deform and reduce coating adhesion, but too thick will likely shrink, affecting the appearance. In general, thin-walled cannot be less than 0.9mm, thick wall cannot exceed 3.8mm.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Explanation of Tungsten Heater for Vacuum Plating——Carrier Oil

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 July 2016 10:09

Two processes carrier oil and drying and curing of tungsten heater for vacuum plating require the following notices. At first, in the respect of structure, part of the vacuum coating layer is composed of a layer (carrier oil), plating (coating) and surface (surface oil) three parts. Carrier oil are used to mask or make up for possible small defects on the surface of products, such as pinholes, pitting, scratches, etc., to provide a flat, smooth base surface for vacuum plating. On the other hand, it can improve the adhesion of the film, which play an important role for weak crystallinity, and poor adhesion of plastic film, such as polyethylene plastic and polypropylene plastic. In addition, the carrier oil can reduce or inhibit outgassing amount of volatile matter on a plastic surface, thus ensuring the quality of deposition.

Two processes carrier oil and drying and curing of tungsten heater for vacuum plating require the following notices. At first, in the respect of structure, part of the vacuum coating layer is composed of a layer (carrier oil), plating (coating) and surface (surface oil) three parts. Carrier oil are used to mask or make up for possible small defects on the surface of products, such as pinholes, pitting, scratches, etc., to provide a flat, smooth base surface for vacuum plating. On the other hand, it can improve the adhesion of the film, which play an important role for weak crystallinity, and poor adhesion of plastic film, such as polyethylene plastic and polypropylene plastic. In addition, the carrier oil can reduce or inhibit outgassing amount of volatile matter on a plastic surface, thus ensuring the quality of deposition.

This requires that the adhesion of carrier oil and plastics should be good, which cannot react chemically with the coating film, and have similar softening temperature to plastic parts. Carrier oil is actually lacquer type organic coating, usually use modified polyester-modified polyurethane varnish or paint as a base material. In process of the carrier oil, operators should maintain the cleanliness of injection mold parts, the oil should be uniform, do not gather the oil to avoid scratch. Workshop environment should keep dry, dust and moisture. When arrange the oil, it should be in strict accordance with the requirements of the process.

Vacuum plating process also includes derosination. Derosination is to clear dirt and greasy oil on the surface of the injection mold parts in order to ensure adequate coating adhesion. General degreasing agent uses an organic solvent degreasing, selection principle of the organic solvent is not to prejudice the plastic surface, and it should evaporate quickly. In fact, in addition to the method of degreasing organic solvent, there are acidic degreasing, alkaline degreasing and others.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Fuel Cell Cathode Composite Catalyst -- Pyrochlore Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Monday, 18 July 2016 21:40

The study found that adding the transition metal oxide into the precious metals will help improve the electrocatalytic activity. Tungsten oxide can form the synergistic catalytic effect with the noble metal platinum, and perform quite stable in an acidic environment, the composite catalyst uses tungsten trioxide as the carrier has been extensively studied. Pyrochlore tungsten trioxide has a layered structure of multi-dimensional channel, also has a three-dimensional channel, and this structure is conducive to rapid migration and ion exchange to improve the ionic conductivity; at the same time, it enhances its adsorption property, certain amount of ions embedded in the layered structure to form intercalation compound catalytic material.

The study found that adding the transition metal oxide into the precious metals will help improve the electrocatalytic activity. Tungsten oxide can form the synergistic catalytic effect with the noble metal platinum, and perform quite stable in an acidic environment, the composite catalyst uses tungsten trioxide as the carrier has been extensively studied. Pyrochlore tungsten trioxide has a layered structure of multi-dimensional channel, also has a three-dimensional channel, and this structure is conducive to rapid migration and ion exchange to improve the ionic conductivity; at the same time, it enhances its adsorption property, certain amount of ions embedded in the layered structure to form intercalation compound catalytic material.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Anti-Sulfur Poisoning of Fuel Cell Catalyst WO3-Pt/C

- Details

- Category: Tungsten Information

- Published on Monday, 18 July 2016 21:37

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com