Influencing Factors of Tungsten Electrode Arc Performance

- Details

- Category: Tungsten Information

- Published on Friday, 29 July 2016 14:18

The arc performance refers to arc ignition capacity, arc stability, arc pressure, temperature distribution characteristic and arc compressibility and directivity, namely static and dynamic characteristics of the arc. During welding, the physical and chemical properties, mechanical properties, chemical composition and structure of electrode will have some effect on the arc performance and to understand these influencing factors on the arc performance can improve electrode’s welding performance.

Chemical Composition:

Doped with rare earth oxide with different types and different contents, the arc performance of tungsten electrode is also different. Generally tungsten electrode doped with three different rare earth oxides has better arc performance than electrode which doped with two different rare earth oxides and doped with single rare earth oxide. In addition, the distribution and temperature properties of rare earth oxides will have a certain impact on the arc performance and arc stability. The electrode which is uniformly distribution and slower evaporation rate has better arc performance.

Organizational Structure:

Integrity and uniformity of the tungsten electrode structure has a direct effect on the arc performance. If there is splitting, delamination, micro-cracks, voids, inclusions or severely uneven grain structure in the electrode inner, it will affect electrode’s arc performance, so during the arc process will cause arc breaking, arc blasting, or drifting, but also will affect electrode’s thermal conductivity and electrical conductivity, so that the electrode locally overheated, melt, deformation, worsen electrode performance.

Physical and Mechanical Properties

the tungsten electrode, having high melting point, high boiling point, low vapor pressure, good thermal and electrical conductivity, high temperature strength, good creep resistance and high recrystallization temperature, has better arc performance.

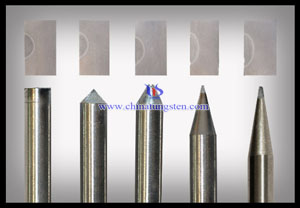

Shapes

Tungsten electrode can be made in different shapes depending on the application. The shape of the electrode, especially the shape and angle of the end portion has significant influence on the arc performance. The flat end requires higher arc voltage and current and the tip portion requires lower voltage and current. Smaller angle is good for arcing, but the deformation resistance is poor, thus determining the angle of the electrode end portion depends on the welding conditions.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com