Tungsten Carbide Button Used for DTH Drill

- Details

- Category: Tungsten Information

- Published on Monday, 04 July 2016 15:38

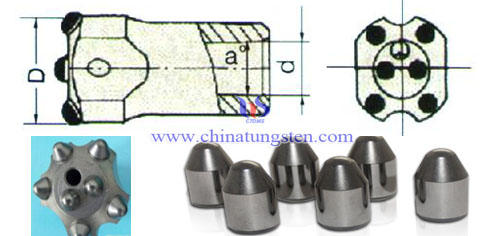

DTH drill uses compressed air as a power source to drive DTH hammer piston, and high frequency impact DTH drill by large impact energy. At the same time, the axial pressure and rotary torque effect from drilling bars rotate and break the rocks. The debris they produce high-pressure air is carried back to the earth surface. This kind of DTH drill has many advantages, such as high drilling efficiency, high quality of drilling, long service life of drill bits, not easily to be blocked and low cost, which as a kind of efficient drilling process and has been widely used in Mine blast, geological exploration, hydrology well drilling and other drilling purposes, especially effective in medium hard and hard formation. However, tungsten carbide buttons used for DTH drill directly affects DTH drill performance. Since in the process of drilling, the button under the action of high-speed impact of high frequency impact energy to hit the rocks, resulting in a larger volume breaking, DTH drill has higher efficiency. In addition, tungsten carbide buttons crush rock is a dynamic, non-linear failure process, which can be divided into 3 steps:

1. The moment of button and rock contacting, the load is small and rock has elastically deformed, and it appears a hemispherical elastic region under the button;

2. The buttons move down continuously, the load and the elastic region increases, the stress wave uses the point of button and rock contact as the center of the sphere, concentric spherical shape continuously to spread inside the rock. Meanwhile, it appears a high-stress area under the contact point of button and rocks. When the stress reached the limits of zone status, rocks were fractured;

3. The buttons intrude the rocks further, pressure on the surrounding rock to the side and gradually increased, eventually collapse from the surrounding rocks, forms a large volume of crushing, crushing cavity is formed.

In general, DTH drill uses 9 buttons, the bottom surface 3 by a clockwise spiral arrangement, other 6 edge evenly distributed. The bottom sets 3 buttons to ensure that each button can endure the largest impact energy, and the closest to the center uses inlay welding process, which is beneficial for coring. The other 6 edge buttons play a role in holding aperture and breaking the rocks surrounded.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Cobalt Alloy Production Using Tungsten Powder Coating

- Details

- Category: Tungsten Information

- Published on Friday, 01 July 2016 18:25

During production of tungsten cobalt alloy, to prevent sticking, aluminum oxide with ethanol is brushed to the boat. However, aluminum oxide will penetrate into alloy under high temperature will results in the uneven of bottom to enlarge the finish machining cost. At the same time, the service life of vacuum pump is shorter with absorption of aluminum oxide particle. This article introduces a tungsten cobalt alloy production using tungsten powder preparing method, it will realize the completely separation of tungsten cobalt alloy and graphite boat and will not affect quality of alloy.

Tungsten cobalt alloy production using tungsten powder coating manufacturing method:

A.Submicron tungsten powder preparation:

1.Disolve tungstic acid in distilled water, adding ammonium solution and heating, ammonium tungstate solution is obtained.

2. Quick freeze ammonium tungstate solution under 45~-50°C.

3. Transit ammonium tungstate into ultra freezing drying machine. After freezing out its appearance is like white cellular piece.

4. Smash the piece obtained from step 3.

5. Tungsten powder is obtained under 250~500°C by hydrogen reduction for 4~6 hours.

B. Preparing materials below:

PEG6000 10~20 parts.

Tween 80 5~10 parts.

Graphite glue 10~20 parts.

Anti-brasive carbon black 10~20 parts.

Submicron tungsten powder from step A 5~10 parts.

Water 30~50 parts.

C. Mixing tungsten powder and PEG6000.

D. Dissolve material in step C with distilled water.

E. Adding the rest material into solution of step D and stirring it evenly.

Advantages: This kind of tungsten cobalt alloy production using tungsten powder coating manufacturing method, use freezing tungsten powder to replace metal oxide powder, it has high purity, small grain size. Besides that, submicron tungsten powder produced by vacuum freezing drying method can absorbing other components when blended with coating due to its porosity inside.

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

High Temperature Resistance Inorganic Tungsten Powder Coating

- Details

- Category: Tungsten Information

- Published on Friday, 01 July 2016 18:23

High performance propellant increase the temperature of solid rocket engine fuel gas, this requires the materials of high melting point and anti-impact. When temperature reaches 3000°C by 2000°C /s, there are huge temperature gradient and thermal press. Common metal material can hardly bear high power burning and physical crush of solid particle results from burning and explosion of rocket propellant. If erosion is severe, it will affect thrust and efficiency of generator.

Using coating technology will do benefits for the high temperature protection of metal parts. The common used coatings are refractory metal and alloy, refractory ceramic material、carbon material, boride and C/C composite material. But it has apparent shortcomings which are complex preparation processes, it is difficult for large and complicated structured accessories.

The components of environmental friendly high temperature resistance inorganic tungsten powder coating introduced in this article are: 20~60% liquid silicate, 3~20% phosphate aluminum powder, yttrium stable zirconium oxide powder 5~50%, tungsten powder 5~50%, titanium carbide powder 5~30%, zinc powder 5~25%. Among which, liquid silicate is the mixing solution of potassium silicate and sodium silicate. Silicate in solution takes part of 30~40%. Using distilled water to adjust viscosity of coating, the weight rate of the above material and water is 1: (4〜10).

Producing method:

1. Mixing phosphate aluminum powder, YSZ powder, tungsten powder, titanium carbide powder and zinc powder.

2. Adding the blended material into liquid silicate and stirring fully.

3. Adding distilled water. Stirring them by 1500〜2500rpm for 30 minutes in the stirring machine, the coating is obtained by going through 200 mesh.

Advantages: Using silicate as film forming matter, tungsten powder and titanium carbide powder can show high temperature resistance property of coating. Zirconium oxide has high temperature resistance property as well as low thermal conductivity to lower the temperature, its big expansitivity makes an improvement on low expansitivity of silicate coating to adjust the thermal expand of metal and avoid falling off.

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

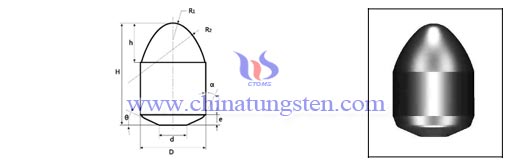

Tungsten Powder and Ferromagnetic Bullet

- Details

- Category: Tungsten Information

- Published on Friday, 01 July 2016 18:06

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Heater for Aluminum Film of Car Light - Aluminizing Method

- Details

- Category: Tungsten Information

- Published on Friday, 01 July 2016 16:25

Thickness of aluminum film of automotive light is generally 0.4 ~ 1.2μm, its surface is smooth and clean, and has a high gloss. Method of tungsten heater for vacuum aluminizing of automotive light can be divided into no bottom plating and bottom plating. Users can select the appropriate aluminizing method in according with the different properties of the substrate.

Polyesters belong to polar polymers, free energy of its surface is high, and its tension is 40dyn / cm or more, which can adhere with the aluminum layer well, so it can be used as bottom plating. That means that the protective film can be directly coated on the substrate again. Aluminum protective film can improve mechanical strength, and prevent the aluminum film from harmful gases or substances, which make the coating has a bright metallic luster, excellent gas and light barrier properties, good moisture property, heat resistance, puncture resistance. In addition, in transport and storage of goods, it can maintain smooth and glossy without any pollution and corrosion. Since the PC (Polycarbonate ) main chain contains an esterfunction, in a humidified environment of room temperature, water absorption of based material is high. It is better to aluminizing the products within 2 hours after depanning, if it is stored for a long time, substrate would absorb water and there exist mist after the aluminizing.

PE (Polyethylene ), PP (Polypropylene) and other polyolefin materials and ABS (Acrylonitrile Butadiene Styrene ) belong to non-polar polymer. The free energy and tension of their surfaces are small and rough, so the binding force between the aluminum layers is poor, which would finally affect the quality of coating. Therefore, these materials are generally used for aluminizing after pre-primed in order to improve the binding force between the coating and the substrate. Plastic parts of automotive light mostly made after pre-primed aluminum and then coated with a protective film.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Heater for Aluminum Film of Automotive Light - Aluminizing Substrate

- Details

- Category: Tungsten Information

- Published on Friday, 01 July 2016 16:23

The lighting system of a motor vehicle consists of lighting and signalling devices mounted or integrated to the front, rear, sides, and in some cases the top of a motor vehicle. This lights the roadway for the driver and increases the conspicuity of the vehicle, allowing other drivers and pedestrians to see a vehicle's presence, position, size, direction of travel, and the driver's intentions regarding direction and speed of travel. Emergency vehicles usually carry distinctive lighting equipment to warn drivers and indicate priority of movement in traffic. Automotive light are divided into the headlight lamps, fog lights, tail lights and other decorative lights. Fog lights will be opened as a warning for other vehicles in rain, fog, snow and other low-visibility weather conditions. Its aluminizing component is reflector. Taillights include turn signals, brake lights, rear fog lamps, reversing lights, etc., its aluminizing parts is lamp body.

The substrates of aluminizing part of the lights are based on polycarbonate, acrylonitrile - butadiene - styrene, polypropylene, PBT (polybutylene terephthalate). Lamps require thermal temperature of polycarbonate material should above 185℃. Taillights can endure temperature below 80℃in average, which is lower than headlight, what’s more, its lamp structure is relatively simpler.

Heat resistance of substrate for vacuum aluminizing should be better, and the content of volatile substance should be lower. In the tungsten heater for aluminizing process, the substrate would affect by radiant heat of evaporator source and heat of evaporation evaporant, if the heat resistance of the substrate is poor, during the heating time it will have thermal deformation, and finally result in wrinkles and shrinkage of coatings. In addition, small molecules volatiles inside the substrate are easy to evaporate, which has an impact on the quality of aluminum layer. Therefore, content of the small molecules volatiles inside the substrate should be very low.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sintering Process Effect on Tungsten Copper Electrode Properties

- Details

- Category: Tungsten Information

- Published on Friday, 01 July 2016 15:01

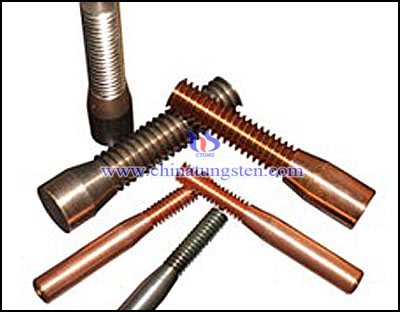

Except the effect of tungsten copper powder itself granularity and distribution and the impurities on tungsten copper electrode properties, the parameters of sintering process control will affects the performance, which mainly from two aspects: one is effects of molding pressure, the other is the influence of sintering atmosphere. In the process of molding, the sample usually has three changing steps: 1. sliding stage, the compacts density increased rapidly at this time; 2. on the basis of the first stage and pressing, the porosity decreased, the compacts density almost not change; 3. when the pressure exceeds a certain value continues to increase, as the pressure continues to rise, the relative green density continues to increase. On the one hand it is due to increase in pressure increases the degree of densification material in the press of the third stage, i.e. when the pressure exceeds a certain value continues to increase, if the pressure continues to increase, the powder is subjected to the pressing force and the friction of its elastic stress, plastic deformation of the particles to produce a powder filling the gap, to further increase its density; on the other hand, since nano grain has high free energy, if the compaction pressure further increases, the particles will pass plastically deformed and the surface free energy is further increased, the melting point is further reduced. This makes it at lower temperatures can be effectively infiltrate W particles.

In the tungsten-copper composite milling process, with the milling time goes by, there would inevitably bring in impurity metal elements, vacuum sintering can effectively exclude impurity element or an oxide, played the role of purification; and vacuum sintering is also beneficial for removing the absorbed gas, which promote the shrinkage effect at the end of sintering. In addition, to a certain temperature sintering furnace charge time should be protected by inert gas. However, the timing of inert gas is a critical issue. If charging too early, Cu grain on the surface not completely melted and closed, Ar will enter through the gap between the particles of material filling the body had been evacuated holes increases when liquid copper tungsten particles were infiltrated and filling the gap resistance, after the copper melting and closing the material surface to form pores; if charging too late, material surface appeared cracks, and then filled with an inert gas also missed the best time.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Electrode Internal Influence Factors

- Details

- Category: Tungsten Information

- Published on Friday, 01 July 2016 14:59

Tungsten copper materials not only has high hardness, high strength, high melting point, high density, low coefficient of thermal expansion and excellent wear and corrosion resistance of W, but also has perfect plasticity and excellent thermal and electrical conductivity of Cu, so it has been widely used in electrical contact materials and electrode materials. But since there is a big difference in melting point and physical properties of them and completely immiscible, usually choose PM (Powder Metallurgy) as the manufacturing process, which also limit the range of applications of tungsten copper. At present, the major way for the preparation of tungsten copper composite material is W-Cu composite powder high energy ball milling, pressing, sintering, by analyzing the influence of grain size and composition of the powder itself and impurities brought sintering properties, in order to better control each key parameters to achieve high-performance tungsten copper electrode products.

In general, in the process of tungsten copper electrode manufacturing, in order to improve the compacts molding effect, we need to add some chemical agents, such as ethanol, stearic acid and so on. These additives may be directly volatilize or decompose in the subsequent sintering step and form pores between the particles. When the sintering temperature is rising, liquid Cu fluidity becomes poor and the gas can not escape completely and formed closed pores, which has a great effect on the density of tungsten copper electrode. In addition, these additives also likely to break down the formation of some C, H, O and other impurities, the smaller its diameter, has a strong expansion of capacity in the alloy. Thus it more likely to occur at a position higher energy grain boundary phase boundary segregation, etc., and even generate crisp phase, bringing the number of alloy intergranular fracture during fracturing along the increase, decrease overall performance. For the powder granularity, When the powder grain size small to some extent, powder sintering temperature decreased, surface area increased, sintering activity enhanced, which is beneficial for powder alloying. When the powder particle size to the nanometer range, the diffusion of powder has been greatly improved, densification process has been accelerated, and the final density of tungsten copper electrode has been improved at the same time.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Powder Applied in Manufacturing Bullet and Cartridge Case

- Details

- Category: Tungsten Information

- Published on Thursday, 30 June 2016 17:58

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rare Earth Affected Tungsten Electrode Arc Static Characteristic

- Details

- Category: Tungsten Information

- Published on Thursday, 30 June 2016 16:09

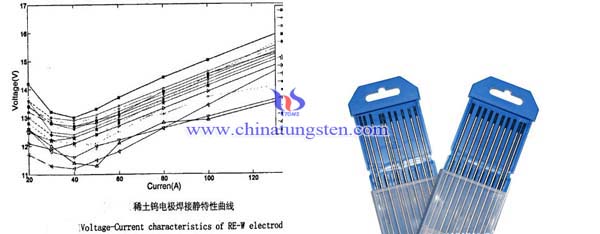

To learn tungsten electrode criticality arcing can understand the difficulty of arcing of electrode, which is one of the important property of the electrodes. However, currently, manufacturers usually using high-frequency for arcing, in general, as long as electrodes arc performance is similar to thorium tungsten electrode that arcing can be quite successful, but it hard to reflect rare earth tungsten electrode’s arcing advantage. Burning performance refers to the burned value of electrode under certain conditions, but it also differ greatly from the actual application operation, so only learned arc starting property and anti-burning property is not enough for complete testing electrode welding property. The welding arcing IU curve also known as arc static characteristic curve which can be more comprehensive performance tungsten electrodes’ welding property.

During experiment, the cathode is water-cooled brass, argon gas flow rate 6L / min, welding load voltage 70V, the arc length 3mm, and the electrode extraction air guide nozzle length is 6mm. After arcing quickly adjusted loop current to 40A, to respectively record the steady-state voltage value, when the current is at 40A, 60A, 80A, 100A, 120A, 140A, 160A, 180A and 200A and the arcing is stable, to obtain static characteristic curve.

From the arc static characteristic curve can be found rare earth tungsten electrode and thorium tungsten electrode has three distinct curves characters including droop characteristic area, flat characteristic area and rising characteristic area. Compared to the thorium tungsten electrode, all rare earth tungsten electrodes exhibit good static characteristics, showing excellent electron emission ability, and they can achieve particular arc current at a lower voltage. Tungsten electrode doped with small amount of rare earth oxide can significantly reduce the work function of the electrode surface and increase electron emission rate, so it has excellent welding property, mainly excited stable static characteristics, superior arc starting and anti-burning property. Doped with La2O3, CeO2 can improve electrode welding performance at small or medium current density. Doped with Y2O3 can improve electrode welding performance at high current density. Doped with a variety of rare earth oxides composite rare earth tungsten electrode has better welding performance than rare earth element tungsten electrodes doped with single rare earth oxide.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com