Tungsten Oxychlorides

- Details

- Category: Tungsten Information

- Published on Friday, 24 June 2016 16:46

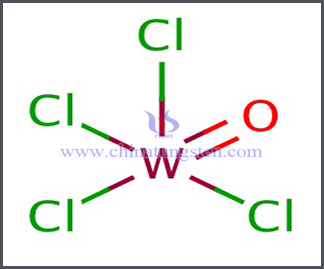

Two oxychlorides of tungsten, respectively WO2Cl2 and WOCl4, are known.

Grades: 98%, 99.9%

Formula: WOCl4

CAS No: 13520-78-0

Form: orange / red crystalline powder

Tungsten dioxydichloride (tungstyl chloride), WO2Cl2, was originally considered to be a chloride of tungsten, and was obtained, although mixed with a certain amount of the oxytetrachloride, by interaction of chlorine with tungsten dioxide. In attempting to prepare tungsten hexa-chloride by the action of sulphur chloride upon tungsten trioxide, Bourion found that the product of the reaction was a mixture of the two oxychlorides only. Further, it is produced by heating tungsten hexachloride with oxalic acid.

This oxychloride forms stable yellow crystals which readily sublime, but which also melt at 259° C; at much higher temperatures the substance largely dissociates into tungstic anhydride and the oxytetrachloride. Partial decomposition is also effected by warming with water. Tungsten oxytetrachloride, WOCl4, is obtained by heating tungsten pentachloride or hexachloride in oxygen, by heating the penta-chloride with oxalic acid, by interaction of phosphorus pentachloride with tungsten trioxide; together with the oxychloride, WO2Cl2, by heating tungsten trioxide in a current of sulphur chloride vapour, by heating the trioxide or oxychloride, WO2Cl2, in the vapour of the hexachloride alone or mixed with chlorine, or by passing dry chlorine over a heated mixture of tungsten trioxide and carbon, the main product being then the oxytetrachloride, which may be obtained in a moderately pure state by taking advantage of its greater volatility than that of the dioxydichloride. It is also formed, together with small quantities of the hexachloride and probably of the pentachloride, when carbonyl chloride is passed over heated tungsten powder.

Tungsten oxytetrachloride forms splendid transparent, ruby-red, needle-shaped crystals which melt at 210° C. and boil at 227.5° C, giving a red vapour of normal density. By water it is decomposed, giving first the yellow oxychloride, and further, hydrochloric and tungstic acids. A certain amount of the yellow oxychloride is also formed from it by loss of chlorine on sublimation in air or oxygen.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trisulphide

- Details

- Category: Tungsten Information

- Published on Friday, 24 June 2016 16:43

Tungsten trisulphide is a brown powder which becomes black when dried. When heated in absence of air it gives up sulphur and forms the disulphide WS2. It may be reduced to the metal by heating with lime in an electric furnace. When heated in the air it yields tungsten trioxide. It is slightly soluble in cold water, more readily in hot, forming a colloidal solution (see below). It is easily soluble in alkali hydroxides, carbonates, and sulphides, forming dark brown solutions which contain thiotungstates and colloidal tungsten trisulphide.

Colloidal Tungsten Trisulphide

It was observed by Berzelius that when the freshly precipitated trisulphide is washed with water, it dissolves to a slight extent, forming a yellow solution. If the precipitate is boiled with pure water it dissolves in considerable quantity, yielding a brownish-yellow solution. Winssinger obtained a dark brown solution of tungsten trisulphide by adding to a solution of sodium thiosulphate a little more dilute hydrochloric acid than was necessary to saturate the alkali. The solution could be passed through filter paper. On boiling, or on the addition of electrolytes, the tri-sulphide is precipitated.

A sulphochloride of tungsten, 3WS3.WCl6, has been obtained by heating the hexachloride with liquid hydrogen sulphide in a sealed tube for thirty-six hours at 60° to 65° C. It is a brown powder, insoluble in carbon disulphide, alcohol, or benzene; it is decomposed by water. If heated to redness in the air, it takes fire. It is readily oxidised by nitric acid or fused potash.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Heater and Kinescope

- Details

- Category: Tungsten Information

- Published on Friday, 24 June 2016 16:36

The metal is heated in vacuum to evaporate on the surface of the object which is going to be deposited, and then form a thin film, that is vacuum coating process, which is now widely used in electronics, glass, ornaments and other production areas. Now most users at home and abroad choose tungsten heater that stranded by tungsten wire as a heating element for vacuum coating. What’s more, the kinescope deposition process is mainly used wolfram heater as a heating element.

Kinescope, shortened to kine, also known as tape-recording in Britain, is a recording of a television program on motion picture film, directly through a lens focused on the screen of a video monitor. Typically, the term can refer to the process itself, the equipment used for the procedure (a 16 mm or 35 mm movie camera mounted in front of a video monitor, and synchronized to the monitor's scanning rate), or a film made using the process. Kinescopes were intended to be used for immediate rebroadcast, or for an occasional repeat of a pre recorded program. In order to reproduce high-quality images, it requires that the screen size of electron ray tube should be large, higher-resolution images and the screen has sufficient emission brightness.

The fluorescent screen of this beam tube composes of screen glass, a phosphor layer and an aluminum film. On the surface of the glass inside CRT screen, which is deposited phosphor with a thickness of 10μm. An aluminum film with a thickness of 1μm is deposited on the outside of the phosphor layer. This film layers are connected to the graphite, it can accelerate the electron beam, and it can also protect the phosphor, so that it will not be damaged because of an ion spot formed by ions, which shows the importance of the aluminum layer. This aluminum layer is formed by tungsten heater as a heating element in evaporation.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Life Time of Tungsten Heater for Kinescope Evaporation

- Details

- Category: Tungsten Information

- Published on Friday, 24 June 2016 16:34

Generally, tungsten heater, also known as wolfram twisted spiral, which is used as a heating element for kinescope evaporation. Heating the metal in vacuum, and the metal would be evaporated by tungsten heater to the sub-surface of the workpiece which is going to be evaporated, and finally form a thin film, this process is evaporation coating. This process requires heating elements should have a good thermostability and corrosion resistance. Currently, users as home and abroad commonly choose spiral coil which is twisted by tungsten wire into various shapes as tungsten heater.

But in the deposition process, the life time of tungsten heater cannot be sustained for a long time, it is unable to meet the requirements for a stable life time, which would severely reduce automation efficiency of kinescope evaporation. The main reasons of their life time are recrystallized structure of tungsten, and the amount of insertion of aluminum.

The test showed that the more the grain boundary on surface of wire, in other words, the smaller grains, the easier diffusion of aluminum, which will lead to tungsten twisted spiral begin to deform even break and eventually end of its life time. Another primary reason is the amount of insertion of aluminum and its fluidity. During kinescope deposition process, in general, manufacturers would like to inset more aluminum than theory insertion of evaporation, which will produce residual aluminum and these residues will continue to react with the tungsten after each evaporation, and the it would finally generate W-Al compounds that can contaminate the tungsten wire, and it would significantly shorten the life time of the heater element. Practice has proved that, compared to the situation of aluminum residues, the evaporation which have no aluminum residue will increase the life time of heater element. In short, with the increase of the amount of insertion of aluminum, the life time of tungsten element will be shortened.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Powder and W-Cu Composite Powder

- Details

- Category: Tungsten Information

- Published on Thursday, 23 June 2016 17:59

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rare Earth Affected Tungsten Electrode Workability

- Details

- Category: Tungsten Information

- Published on Thursday, 23 June 2016 17:40

Adding different content of rare earth elements into tungsten electrode may have different effects on the workability of the electrode. Rare earth particles can hinder tungsten grain deformation. Adding rare earth elements into tungsten electrode, the deformation resistance of the electrode will increase which need to reduce the amount of processing pass in processing. Further, the crystallization temperature of rare earth tungsten electrode is higher than pure tungsten electrode, so during processing need to appropriate increase processing temperature.

In rare earth tungsten electrode, rare earth phase particle size is about 1 ~ 2um and tungsten particle size is about 10 ~ 20um. During processing, tungsten particle will first to deformation showing flat structure. With the in-depth processing, tungsten particle continue flattening showing fibrous structure. With deeper processing, rare earth particle started to deformation and the structure extends along the direction of deformation. At this time larger rare earth particles break into small particles distributed parallel to the deformation direction. At the drawing stage, rare earth particles break into 1um small particles. The rare earth particle became finer making the structure of rare earth tungsten electrode more uniform, so during processing, electrodes can compatible deformation and can withstand greater deformation.

To understand the impact of rare earth on tungsten electrodes hardness the manufacturers use nano-hardness tester for testing. Putting the pressure head in tungsten substrate the hardness curve peak value is about 6.4GPa, and then to decrease. With the increase of the amount of pressure, the curve is decline, indicating that the mechanical characteristic of rare earth particles proportion is growing. When the penetration depth is 900um, showing rare earth hardness value is about 5.4GPa. From this we can see that the hardness of rare earth particle is less than the tungsten particles’. Therefore, under the same conditions, the rare earth particles more easily to deform. Compared to the tungsten particles, with further processing, rare earth particles more easily break into small particles, which is good for subsequent processing.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode Application

- Details

- Category: Tungsten Information

- Published on Thursday, 23 June 2016 17:38

Tungsten electrode widely used in welding industry. In plasma arc, cutting and non-consumable welding and other welding manufacturers usually use thorium tungsten electrode, but because thorium tungsten electrode has a radioactivity having some impact on the environment and human health. The radioactivity of thorium tungsten electrodes is about 13.22 x1015Bq / kg. With further research and innovative technology, manufacturers developed different rare earth tungsten electrodes which have different properties to the place of high-performance thorium tungsten electrode, and the cerium tungsten electrode and lanthanum tungsten electrode used more widely. To produce cerium tungsten electrode by doped with 2% ~ 4% cerium oxides, and cerium tungsten electrodes commonly used in DC, because it is not only easy arcing and has low electrode burning rate, but also the welding current density is greater than thorium tungsten electrode. However, using in AC welding, the burning rate will be higher than thorium tungsten electrode and the allowable range welding current is less than the thorium tungsten electrode.

Tungsten electrode can also be used in the field of electric light source. Rare earth tungsten electrode has a low work function, high melting point and low vapor pressure, so it is often used as discharge electrode material in lamp. Tungsten electrode has corrosion resistance, high temperature performance and other excellent performance which can reduce the load temperature, reduce the electrodes burning rate and corrosion, thereby extending lamp life. Thorium has low soluble degree in tungsten, so thorium tungsten electrode used in lamp not only can maintain the low work function, but also can generate stable electrode arc. In order to expand the tungsten electrode range of application in electric light source fields, the researchers through the liquid - solid method to produce low-power metal halide lamp electrodes and to assemble into a 70W metal halide lamp, compared to the application performance of different rare earth tungsten electrodes in the lamps found splash performance dysprosium tungsten electrode and dysprosium yttrium electrode has good splash-proof performance and corrosion resistance performance which has the similar performance with thorium tungsten electrode.

Tungsten electrode is also used in the plasma generator. Arc plasma with high temperature heat source, energy concentration and high efficiency heating and other good performance, are widely used in cutting, thermal spray field, welding, melting, new materials synthesis, ultra-fine powders manufacturing and other field. The cathode in the plasma generator should withstand the heat radiation and high-energy ion bombardment and erosion, and tungsten electrode has high strength, corrosion resistance and high temperature resistance and other properties, it is considered the best cathode material in the plasma generator.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Heater and Tungsten Stranded Wire

- Details

- Category: Tungsten Information

- Published on Thursday, 23 June 2016 17:33

Tungsten stranded wire is a kind of strip tungsten products made of a certain specification of diameter of a number of tungsten wire, which is mainly used to produce tungsten heater. In the vacuum coating, tungsten wire cutter is a consumable material. Now it is widely used in kinescope, mirror, mobile phones and all kinds of plastic, metal and organic substrates and various accessories and other surface spraying industry.

As the main raw material of tungsten heater, the quality of tungsten stranded wire will directly affect the quality of tungsten heater which will have a greater impact on the coating effect. Therefore, surface of stranded tungsten coil should be glossy silver color without any visible contamination, no and there are no obvious cracks and oxidation glitches on the surface. Each twisted tungsten wires cannot have any breakage, and the spiral coil should have flexibility to a certain extent. The deviation of size of a tungsten wire should be consistent with the secondary deviation of GB4181. The life of this tungsten product should be longer than 12 times during the deposition of aluminum.

Each package must be marked with a memo or a certificate of products, and indicates that the manufacturer's name, trademark, material’s name, batch number, specification, weight, date of manufacture, inspection department stamp. The wrapped Stranded tungsten wire should be placed in the room whose relative humidity is below 65%, and there is no acid and alkali gas. It is marked with the words "Handle with Care", "anti-moisture" and others while transport. And the cases should avoid the erosion of acid gases and snow damage.

Wolfram heater generally use grades HW41, HW42 tungsten wire as raw materials. The wolfram heater made by the professional equipment would have a high melting point, good corrosion resistance, long life time of deposition and other excellent characteristics.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Used for Vacuum High-voltage Switch

- Details

- Category: Tungsten Information

- Published on Thursday, 23 June 2016 15:51

Tungsten copper composite materials have widely used in electrical contacts, high voltage switches and breakers, especially in high voltage SF6, air / oil medium, large current circuit breaker. Recent years, with the rapid development of vacuum high-voltage switch, the contact materials have some innovation correspondly. Compared with other contacts, vacuum contact materials have higher requirements. Except the normal properties of switches, due to the surface of contact is particular clean, which will be easier welded in the air. So based on high resistance to weld, it also needs higher welding resistance, higher anti-electric erosion, low cut-off current and low content of gas. And tungsten copper excellent properties can perfectly meet the needs of high-voltage switch contacts.

From compression molding, for tungsten copper sheet contacts, CIP (Cold Isostatic Pressing) has good forming performance, but it has higher equipment investment and lower material utilization. The mechanical molding should be noted that the gap of molding tools and tungsten powder granularity. The smaller gap will cause the difficulties in stripping; the larger gap will make tungsten powder scratch the mold and produce the cracks on the surface of compact. From sintering process, porous tungsten skeleton sintered is the key process of tungsten copper manufacturing. High-temperature sintering is easy to remove impurities and ensure the electrical conductivity and the gas content meet the requirements. In addition, during the sintering process also need to consider the tungsten powder particle size, size distribution and pressing density. Too low temperature will increase the porosity and reduce the density and hardness of products; too high temperature will reduce the content of Cu and the electrical conductivity decrease. Overall, choose pure tungsten powder as raw material, mechanical molding, sintering furnace hydrogen reduction, hydrogen protection copper infiltration process to produce high-pressure vacuum switch tungsten copper material, it has high strength of porous W skeleton, low gas content, Cu has network-like distribution, tungsten copper matrix bonded tightly.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Acid Solution for W and Cu Separation from Tungsten Copper Scrap

- Details

- Category: Tungsten Information

- Published on Thursday, 23 June 2016 15:48

Tungsten (W) has high hardness, high strength, high toughness and many advantages, which in the state of pure metals and alloys are widely used in modern manufacturing, such as tungsten carbide, tungsten heavy alloy, heat resisting alloy, wear-resistant alloy, electrical alloy, vacuum components, contact switches and so on. And it has been gradually become the indispensable materials for chemical industry, metallurgical industry, machinery industry, petroleum industry, aerospace industry, nuclear industry and the defense industry. Tungsten as an important strategic resource, our country has rich mineral resources of tungsten and the total output and export is the first place around world. However, according to the speculation of the experts and scholars, tungsten resources in mining 50 years will face severe shortages of various countries are also concerned about the recycling of tungsten, especially the recovery of waste alloy.

According to related statistics, the country has dozens of tons of waste each year nearly tungsten copper alloy no suitable recovery method to separate and use, resulting in great losses and waste. Currently the more common methods include saltpeter melting, chemical substitution, electrolysis, high temperature oxidation, phosphoric acid extraction method, zinc melting evaporation method, etc., but these processes are relatively complex and lengthy process, and the relatively high cost, poor stability, which can not be suitable for industrialization widely used. So we introduce a acid solution to effectively separate W and Cu from tungsten copper scrap. It is based on the principle that copper reacts with the acid, and tungsten does not react with the acid. Common tungsten copper alloy scrap, such as contacts, electrical switches, copper tungsten alloy electrode, vacuum components, ion bombardment heating used tungsten copper alloy. Waste tungsten copper alloy of copper content is generally 10-40% tungsten content is generally 60% -90%. Since Cu by means of capillary infiltrated into the porous W skeleton sintered or impregnated with copper liquid, which provides a good condition for acid solution to separate tungsten copper alloy.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com