Tungsten Carbide Die Status Quo

- Details

- Category: Tungsten Information

- Published on Thursday, 16 June 2016 16:00

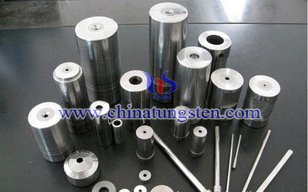

Currently, tungsten carbide material has become an indispensable role in the mold manufacturing. With the increasing complexity of the products and the higher requirement of the performance, the relevant researchers develop new carbide materials research as one of the directions. Several years ago, new carbide material mainly used Fe, Ni to replace Co, which usually used for cold heading die and cold extrusion die with high demand of toughness (such as YG15, YG20, YG25). Recent years, the hotpot turns to ultrafine grained and nano-crystalline carbide and gradient structure of cemented carbide. Fine-grained and ultrafine grain cemented carbide has been available, as YG8 fine grain carbide drawing dies in less than 1mm wire control, efficiency is three times the normal drawing die. Gradient cemented carbide is also divided into content gradient and structure gradient, they often fabricated by metal solution penetrated treatment. In addition, cast tungsten carbide heat die has a better performance in tube and wire rolling.

Based on the mechanism of tensile deformation of the metal mold uneven wear, Researchers have proposed the maximum and minimum drawing angle theory. They found that the gap between domestic and foreign mold die life lies in the angle of the design. Foreign mold at the bottom of the mold core and the mold housing bore center of the bottom-contact parts adopt double convex design, it is possible to force the center of the largest snug fit around the pore and for an interference fit. So some domestic manufactures have also been inspired, and correspondly make some improvements in the structure. Especially the improvements on the design of hexagonal carbide die, which changed into six casement combination so that it can save the consumption of tungsten carbide and convenient for assembling and changing. In terms of machining and assembling technologies, tungsten carbide usually uses hot or cold casement and vacuum brazing.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com