Tungsten Heater for Evaporation Coating

- Details

- Category: Tungsten Information

- Published on Monday, 06 June 2016 10:10

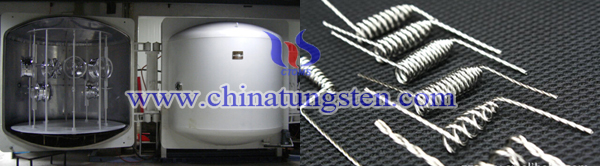

Vacuum evaporation coating has developed rapidly in recent years, glass, plastic, ceramic, metal, and other based material can be coated. Aluminum, copper, silver and their alloys can also be used as the coating material. Most vacuum aluminizing technology use tungsten wire as a heating source (tungsten heater). First of all, the plated workpiece should be clean, load it on a shelf in a sealed room. Accordance to the classification of application, coating machines have been designed into a stationary, rotating and both revolution and rotation and other types. The wolfram heater can be inserted in the position that is close to the plated object, when the degree of vacuum is higher than 5 × 10-4 Torr, the tungsten wire is energized and heated, the molten aluminum will be evaporated into an aluminum atom, and it will condense on the surface of the plated object, forming bright and non-transparent film with 3-5 microinch.

According to statistics, the amount of interpreters which need tungsten heater for vacuum coating is constantly increasing in China. And in order to save the use of silver, China continues to promote the new technology of vacuum aluminizing mirror. And vacuum evaporation coating machine in has been widely used in China. What’s more, the amount of using of tungsten heater is also increasing year by year. United States, Japan, Sweden, Germany and other countries still use wolfram heater, so exports are also on the rise.

Secondly, use value of high quality wolfram heater is twice as much as the poor quality wolfram heater, so improving the quality of wolfram heater has an important influence. In order to reduce the consumption of tungsten, it needs to improve the quality and its reasonable application. If the use of wolfram heater can be stabilized at around 18 times in a week, then the product will be able to meet customer needs.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com