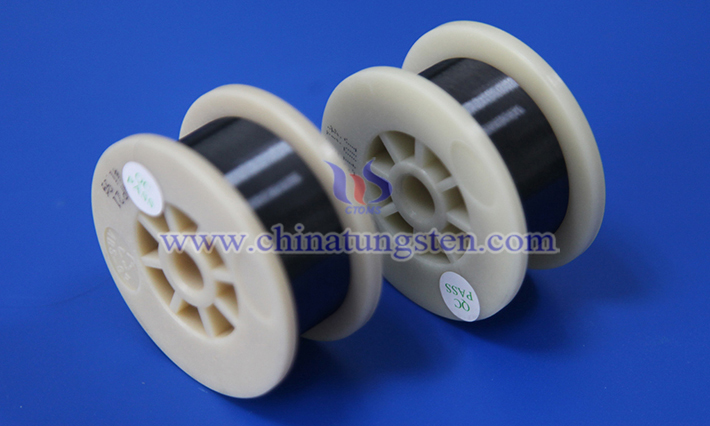

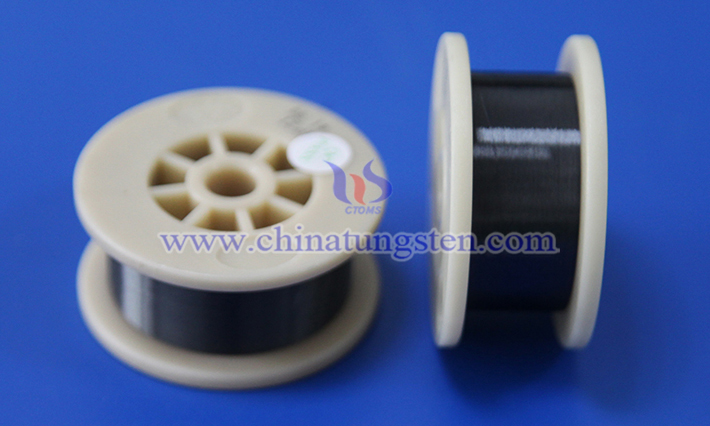

Performance of Tungsten Wire in Glass Heat Treatment

- Details

- Category: Tungsten Information

- Published on Tuesday, 01 July 2025 17:30

The performance of tungsten wire in glass heat treatment is mainly related to its unique physical and chemical properties. The following is an analysis of its performance:

1. High Temperature Stability

Excellent High Temperature Performance: Tungsten has an extremely high melting point (about 3422°C), the highest of all metals, so in the high temperature environment of glass heat treatment (usually between 600°C and 2000°C, depending on the type of glass), tungsten wire can maintain structural stability and mechanical strength, and is not easy to melt or deform.

Resistance to Thermal Fatigue: Tungsten wire shows good resistance to thermal fatigue in repeated heating and cooling cycles, and can withstand frequent temperature changes during glass heat treatment.

2. Chemical Stability

Weak Oxidation Resistance: Tungsten easily reacts with oxygen at high temperatures to form tungsten oxide (WO₃), which may cause corrosion on the surface of tungsten wire or degradation of performance. Therefore, in glass heat treatment, it is usually necessary to use it in a vacuum or inert gas (such as nitrogen, argon) protection environment to prevent oxidation.

Chemical Compatibility with Glass: Tungsten wire has low chemical reactivity with most glass materials at high temperatures, and is not easy to react chemically with components in glass (such as silicates), which ensures the purity of the glass during processing.

3. Electrothermal Performance

Efficient Electrothermal Conversion: Tungsten wire has high resistivity and good conductivity, and is often used as a heating element (such as in glass melting or annealing furnaces). It can heat up quickly and provide a uniform thermal field, which helps to accurately control the heat treatment of glass.

Thermal Radiation Efficiency: Tungsten wire can effectively radiate infrared rays at high temperatures and is suitable for glass heat treatment processes that require radiation heating, such as glass forming or annealing.

4. Mechanical Properties

High Strength and Toughness: Tungsten wire can still maintain high mechanical strength at high temperatures and is suitable for use as a support or heating element, especially in glass heat treatment equipment that needs to withstand certain mechanical stresses.

Creep Resistance: Tungsten wire has excellent creep resistance at high temperatures, is not easily deformed after long-term use, and is suitable for long-term heat treatment processes.

5. Performance in Practical Applications

Glass Melting: In glass melting furnaces, tungsten wire is often used as electrodes or heating elements, which can provide a stable high-temperature environment to ensure uniform melting of glass.

Annealing and forming: Tungsten wire can be used to accurately control the temperature gradient of the annealing furnace, help eliminate internal stress of the glass or achieve specific shape forming.

Special Glass Processing: In the production of high-performance glass (such as quartz glass or borosilicate glass), tungsten wire is widely used due to its high temperature resistance and chemical stability.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com