Tungsten Powder made by Waste Tungsten Bar- Chemical Vapor Migration

- Details

- Category: Tungsten Information

- Published on Monday, 30 May 2016 10:13

With the rapid development of industry, although it has high economic benefits, but the damage of the environment is on the increase every year. Due to ecological environment worsening and water resource shortage, the human living environment will face the serious challenge. The ecological environment is fragile, and the task of ecological construction and environmental protection is still heavy. And therefore countries pay more and more attention to the recovery of metals. Japan set up a special committee for tungsten recovery in 1975, which is called WR for short. The commission estimates that 31.3 tons of tungsten can be recycled while producing 100 tons of carbide. Or we can say that is the 31.3 percent recovery, the actual recovery rate in Japan is 10% and the United States is 20%. The equipment for chlorination pulping process is relatively simple, and it has a wide adaptability of raw materials, at present, this method is considered as one of the most promising methods. In recent years, ultrafine tungsten powder extracted from the waste tungsten bar through the chemical vapor migration has aroused general concern. Chemical vapor migration is a chemical process used to produce high quality, high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films. Microfabrication processes widely use this way to deposit materials in various forms, including monocrystalline, polycrystalline, amorphous, and epitaxial.

The first is to use chloridize the cutting of both ends of the clamping head of tungsten bar while vertical sintering at environment of 950 ℃. Chloride will be supplied to reduction tubes with argon, and then being deoxidized by hydrogen. Chlorine is loaded in industrial bottle, and mixed with argon after dehydrating by concentrated sulfuric acid. Deoxidizing hydrogen with palladium asbestos at the temperature of 350 ℃, then drying it by silica gel and molecular sieve. Finally, gathering the ultrafine tungsten powder obtained by the reaction in powder collecting pipe. After purifying and absorbing hydrogen chloride, exhaust gas which contains hydrogen would be emitted and combustion. The final wolfram powder would have 0.64% oxygen, 0.075% chlorine, and 0.033% chlorinated residue.

Adopting chemical vapor migration methods can also produce the same quality of wolfram powder. Although the aluminum content is higher, all other metal impurities are mostly below or equal to the ultrafine wolfram powder. On the one hand, it can greatly reduce industrial costs. On the other hand, it helps to promote the application of wolfram powder.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Bar and Satellite

- Details

- Category: Tungsten Information

- Published on Monday, 30 May 2016 10:10

In the context of spaceflight, a satellite is an artificial object which has been intentionally placed into orbit. Such objects are sometimes called artificial satellites to distinguish them from natural secondary planets such as moon. The world's first artificial secondary planet, the Sputnik 1, was launched by the Soviet Union in 1957. In the whole solar system, except for Mercury and Venus, the other planets are all natural objects. Wolfram is a rare non-ferrous metal in the world, and its annual output is very low. In addition, it is very versatile and mainly applied in the casting material. Nowadays, the total number of natural objects is at least 160. For example, in the solar system, the sun is a fixed star, and the earth and other planets orbit around the sun, and the moon and other planets orbit around the earth, these planets are called natural secondary planet.

Not long ago, there has been a weapon called satellite powered gun, which is also known as "God's scepter." This is an extraterrestrial combat device which is still being researching and developing. Theoretically, this weapon can shoot to the ground with tungsten bar through its track, and it can cover any range of the entire planet. Tungsten metal is lustrous and silvery white in color, and does not occur naturally (it has an abundance of 1 ppm in the earth's crust). Attack that originates from space, not only has the capability to destroy large tracts of ground buildings, but also destroys hundreds of meters deep underground bunkers. Powered gun can hit the ground by gravity, and it can be accelerated to the speed of 3403 m / sec which is the same as the destruction of nuclear weapons, but it would not cause catastrophic nuclear radiation.

In the movie "GI Joe 2", it is mentioned that the "silos" can be considered as a geostationary secondary planet, tungsten bar will do elliptical motion around the earth with "silos" in the absence of thrust. However, according to the law of conservation of energy, kinetic energy of landing of this type of tungsten products does not exceed its own potential energy of the near-Earth orbit, and its potential energy in the near-Earth orbit cannot exceed kinetic energy of its rocket launching. So, in fact floor kinetic energy of tungsten bar is probably less than a quarter of the rocket fuel energy, and therefore, such weapons are currently still in the theoretical condition.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nano Tungsten Carbide — SPS Process

- Details

- Category: Tungsten Information

- Published on Friday, 27 May 2016 17:53

Spark Plasma Sintering (SPS) is a kind of new sintering technology based on electrical discharge machining. It belongs to plasma sintering technology, which uses sparks and gap discharge to sinter in pressure. While the other is in a vacuum environment, uses 5000-20000k plasma flame to heat sintering, this called thermal plasma sintering. The basic principle of SPS is that use the instantaneous high temperature produced by pulse energy, pulse discharge pressure and the Joule heat to achieve sintering process and by instantly generate a plasma discharge inside each particle is sintered to produce a homogeneous particle surface activation and self-heating. Furthermore, SPS process can be widely used in ceramics, cermet, Intermetallic compound, FGM (Functional gradient Material), thermoelectric materials, ferroelectric materials, magnetic materials, nano materials, amorphous alloys fabricating.

In brief, SPS process is to inlet pulse current directly into the powder grains for heat sintering, so it always called as plasma activated sintering or Ion-assisted sintering technology. The plasma generated by pulse current and the pressure in sintering process is beneficial for decreasing the sintering temperature of powders. Meanwhile, the low-voltage, high-current characteristics can promote the powder densification. In addition, due to the high rate of heating and cooling and short holding time can effectively avoid surface diffusion stage and hinder the particles growth. It greatly reducing the production cycle, improve the overall efficiency.

Compared with conventional vacuum sintering process, SPS process has many advantages in nano tungsten carbide machining, such as finer granularity, higher densification, more uniform structure and no apparent porosity defects. While the sample by vacuum sintering has loose structure, leaving a large number of inter-particle porosity, grain growth phenomenon is more evident. Viewed from density, Vacuum sintering to full density sintering temperature is higher than the discharge plasma sintering nearly 300 ℃, sintering time is longer than 6h. And in the process of SPS sintering, the densification of the samples will never decrease when the temperature exceeds an optimum value. This is due to the volatile Co does not appear in the SPS phase sintering process, the sample has been densified with sintering temperature increases; from the view of hardness, Rockwell hardness and micro hardness of sample after the sintering SPS are significantly higher than traditional vacuum sintering samples. It is for this reason that the heat source of vacuum sintering is outside of the sample and the thermal conduction process is outside-in. The surface reaches the sintering temperature in advance, but the internal heat can not be effectively conducted, so there is still some porosity and it is difficult to achieve full densification. In the process of SPS sintering, the presence of spark plasma sintered body such that each particle inside their own uniform heating, surface atomic particles are in an activated state. And the whole densification is synchronous, there is no sequence of densification.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

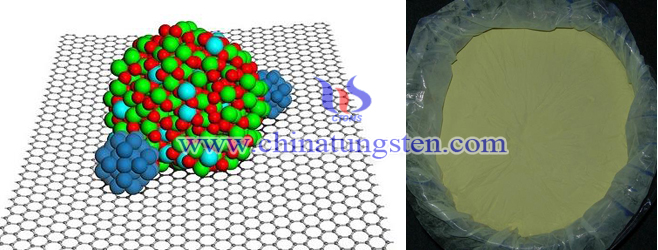

Nano Tungsten Copper Composite Material

- Details

- Category: Tungsten Information

- Published on Friday, 27 May 2016 17:51

Nano tungsten copper composite material is also known as ultra-fine tungsten copper composite material, which compared with common grain tungsten copper, has better mechanical and chemical properties, such as high density, high hardness, high strength, excellent wear and corrosion resistance and perfect thermal and electrical conductivity, etc. Its granularity usually between 1nm -100nm and the nano grain has several characteristics is given as follow:

1. Small size effect: When the coherence length or penetration depth dimension and the wavelength of light particles, de Broglie wavelength and other physical characteristics of the superconducting state of a considerable size or less, crystal periodic boundary conditions will be destroyed, the density of atoms near the surface of the particle layer of amorphous nano-particles reduced, resulting in characteristic sound, light, electricity, magnetic, thermal, mechanical and other changes in the new physical properties;

2. Surface effect: With the decreasing grain size, the ratio of surface atoms and total atoms of nano tungsten copper grains is dramatically increasing and the binding energy of grain is correspondly increasing, which changes the properties of nano grains;

3. Quantum size effect: When copper tungsten particle size down to a certain size, the electron energy levels near the Fermi level from continuous to discrete energy and transformation. During the existence of discrete energy level occupied molecular orbital, at the same time there are also contrary to occupy the lowest molecular orbital, and the spacing between the high and low rail level with the smaller diameter of the nano particles increased;

4. Macroscopic quantum tunneling effect: Electrons have wave-particle duality and the ability to penetrate the barrier, known as the tunnel effect. Macroscopic quantum tunneling effect will be the basis for future microelectronics, optoelectronics, or it further establishes the limits of miniaturization existing microelectronic device;

5. Coulomb blockade and quantum tunneling: In nano scale dimensions, the charging and discharging process is not continuous, filled with an electron energy required is called the Coulomb energy blockage. In such a small system of single-electron transport behavior is known as Coulomb blockage effect, if the two quantum dots connected by a junction, a single quantum dot electrons through the energy barrier to another quantum dot is the quantum tunneling.

Nano tungsten copper composite material has better performance in thermal properties, magnetic properties, optical properties, the super-conducting properties, catalytic properties and so on. From the thermal properties, at extremely low temperatures, the thermal resistance of tungsten copper nano particle is almost zero; from magnetic properties, nano grain will enter super-paramagnetic state when it exceeds a certain threshold and shows high coercivity; from optical properties, nano particle quantum size effect is more significant, in the optical performance of the wideband receiver, the dispersion obtain some special optical properties; and the super-conducting transition temperature of nano tungsten copper grain increases as the decreasing granularity. In addition, from catalysis nature, as the particle size decreases the reactivity significantly increased under appropriate conditions capable of catalyzing the breakage H-H, C-H, C-C, C-O chemical bond and so on.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Shielding And Radiation Protection

- Details

- Category: Tungsten Information

- Published on Friday, 27 May 2016 17:50

With the extensive application of radiation technology in our life, the word "radiation protection" also gradually attracted people's attention. Radiation protection is a comprehensive edge discipline that is defined as "the protection of people from harmful effects of exposure to ionizing radiation, and the means for achieving this". Its main research contents include radiation protection technique, radiation protection standards, radiation dosimetry, radiation protection evaluation and management. Protecting the environment and the health and safety of personnels engaged in radiation related work, public and their future generations, and to promote the development of atomic energy are the basic tasks of radiation protection. The three essential elements of radiation protection are distance, time and shielding, in other words, the main methods of radiation protection are distance protection, time protection and shielding protection. Wherein the shielding protection means setting a radiation shielding material which can effectively absorb the radiation between the radiation source and the human body, in order to decrease the strength of the radiation, and thus to protect the body from radiation damage. Tungsten alloy shielding can effectively shield the radiation, so it is widely used as a shielding material for radiation protection.

With the extensive application of radiation technology in our life, the word "radiation protection" also gradually attracted people's attention. Radiation protection is a comprehensive edge discipline that is defined as "the protection of people from harmful effects of exposure to ionizing radiation, and the means for achieving this". Its main research contents include radiation protection technique, radiation protection standards, radiation dosimetry, radiation protection evaluation and management. Protecting the environment and the health and safety of personnels engaged in radiation related work, public and their future generations, and to promote the development of atomic energy are the basic tasks of radiation protection. The three essential elements of radiation protection are distance, time and shielding, in other words, the main methods of radiation protection are distance protection, time protection and shielding protection. Wherein the shielding protection means setting a radiation shielding material which can effectively absorb the radiation between the radiation source and the human body, in order to decrease the strength of the radiation, and thus to protect the body from radiation damage. Tungsten alloy shielding can effectively shield the radiation, so it is widely used as a shielding material for radiation protection.

The radiation can be divided into ionizing radiation and non-ionizing radiation depending upon its energy level and ability to ionize substances. The term of radiation generally refers to ionizing radiation. Ionizing radiation is widely used in industry and medicine, and can present a significant health hazard. When it is irradiated to the human body, it can cause radiation sickness, and lead to the lesions occur in almost all the body organs and systems, of which the most obvious is the nervous system, digestive system and blood-forming organs. Long-term irradiation by the radiation can also make the body discomfort, resulting in a variety of diseases, such as leukemia, cancer, premature aging, retinopathy, reproductive system diseases. The injury caused by ionizing radiation on the human body can be divided into acute radiation injury and chronic radiation injury. Acute radiation injury means the injury arise from receiving a certain dose of radiation in a short time, which is commonly seen in nuclear accidents and patients undergoing radiation therapy; while chronic radiation injury refers to the injury arise from dispersedly receiving the radiation for a long time, including neutropenia, hematopoietic disorders, skin damage, impaired fertility and so on.

According to the research, the radiation shielding performance of a metal material increases with its density. Due to tungsten alloy shielding has a high density, it has great radiation shielding performance. Placing a tungsten alloy shielding between the radiation source and the body can effectively absorb radiation, reducing the intensity of the radiation, and thus protecting human body from radiation damage. In addition, compared with other traditional materials (such as lead), tungsten alloy shielding is non-toxic, will not endanger human health or pollute the environment, is extremely environmentally friendly shielding material.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Energy Storage Type Tungsten Trioxide Photocatalyst

- Details

- Category: Tungsten Information

- Published on Friday, 27 May 2016 17:33

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nano Pt Supported Tungsten Trioxide Photocatalyst

- Details

- Category: Tungsten Information

- Published on Friday, 27 May 2016 17:31

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

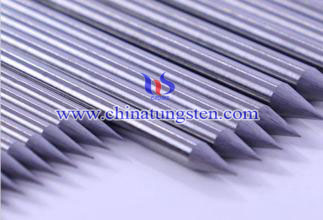

Tungsten Bar and Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Friday, 27 May 2016 10:06

At present, tungsten filament is mainly used as electric light source of electric incandescent lamp, halogen tungsten lamps and others. When using as a luminous body of the filament lamp, a small amount of potassium, silicon and aluminum oxides should be added during the smelting process. This kind of wolfram filament is also known as doped tungsten wire and 218 wolfram wire or anti-drooped tungsten filament. Uniformity condition of density of tungsten bar plays an important role in the quality of tungsten product. The number, size and distributing condition of holes of wolfram bar not only have a greater impact on its high-temperature performance, but also affect the mechanical properties.

Processing tungsten round bars and square bars made from the same batch of tungsten powder raw material. After stretching them to 500W finished wire, using Japan or West Germany crack flaw detectors to detect 50000m wolfram filament respectively. By the force of contrast, it can be found that, the total length of the crack of tungsten wire prepared by round tungsten bar is about 0.98% to 1.20% of. On the other hand, for the same specification of tungsten square bar, crack accounts for 4.21% ~ 58.82% of the entire length of wolfram filament. Obviously, the crack of tungsten filament made by tungsten round bar is much smaller than square bar. Tungsten is widely used as refractory metals. In wire form, wolfram wire is essential for the production of lighting products and other goods where its high temperature properties are of use. Its properties are a melting point of 3410° C, a low coefficient of thermal expansion and low vapor pressure at elevated temperatures along with good electrical and thermal conductivity.

From the perspective of wire-wound performance, under the same conditions, the wire-wound performance of wolfram filament prepared by round bar is better than the square one. According to the spiral resilience, we can see that the helical filament of the tungsten round wire would not crack in the stretching process, and the distance of the pitch is relatively equal. Under the same situation, square spiral filaments have the flerry phenomenon.

All in all, any non-uniformity processing of wolfram bar will cause the deformation of tungsten material, leading to its internal organization become non-uniformity, causing breakage of the inner wall of wire, especially at the junction of uneven tissue, which is more easily to have a crack.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Waste Tungsten Bar and Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Friday, 27 May 2016 10:04

Tungsten powder is in the form of powder of tungsten metal, which is the raw material of manufacturing process of wolfram, tungsten alloy and tungsten products. Pure tungsten powder can be processed into wire, rod, tube, plate and any other shapes. If wolfram powder mixes with other metal powders, it can be made into a variety of tungsten alloys, such as tungsten-molybdenum alloy, tungsten-rhenium alloy, tungsten-copper alloy and high density tungsten alloy. Another important application of tungsten powder is to make tungsten carbide powder, and then the produce cemented carbide tools, such as lathe tool, hobbing, drilling bit and die. Pure tungsten bar includes tungsten rod, tungsten steel bar, tungsten rod, tungsten sintered bars and more, which is mainly used to found ingredient of material, cutter and heads, tungsten wire for lights instruments, electric contact points and conductor of heat, crankshaft and cylinder barrel of advanced automobile, ingredient of kinds of heat-resistant steel.

People are used to abstract the metal from the ore, however, recycling and reproduce discarded metal can not only save energy, reduce costs, but also help to improve the ecological environment. Therefore, this method has attracted serious concern in the world. Especially in Japan, the country takes the project as the development of "second mining", which contains tungsten steel scrap, tungsten metal and its alloy scrap, cemented carbide scrap, grinding debris, dust and other secondary raw materials. Many countries have begun to set up a special department in charge of recycling the waste tungsten. From example, the Soviet Union has established a research institute in charge of the recovery of non-ferrous metal scrap. Through a series of industrial tests, a tungsten-containing waste treatment process developed by the institute is considered as the most promising step. In recent years, many countries are researching and developing how to deal with the waste tungsten bar. The ways to handle waste wolfram bar and reproduce wolfram include electrolytic process, zinc process, high temperature oxidation, chemical dissolution and chlorination pulping process.

It is proved that waste end block of wolfram powder can be used as a raw material instead of industrial wolfram powder, and it can produce the same quality of ultrafine particles. This can greatly reduce the industry costs. What’s more, the most important is the reasonable reuse of resources that can improve evils caused by the rapid development of industry.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rare Earth Affected Tungsten Electrode Sintering Process

- Details

- Category: Tungsten Information

- Published on Thursday, 26 May 2016 19:51

The content of rare earth in tungsten powder at sintering process will affect tungsten electrode sintering temperature and density. And the main reason is due to the dispersal of rare earth in sintering process. As we know, with increasing of rare earth content, the influence of rare earth on tungsten grain is increase. On the one hand, rare earths under heat effect will have diffusion migration occur, and resulting in the distribution of rare earth on tungsten powder is uneven. On the other hand, there is hindered effect of rare earth on tungsten grains growing. So containing large rare earth area sintering is more inadequate. On the contrary, the area where has small rare earth content can completely be sintered. And this is the reason that tungsten grain size has large difference. And part of pores is blocked, resulting in density to reduce. Causing by heat effect the rare earth unevenness will be more severe, and the sensitivity of the process is also more obvious.

One of performance of process sensitivity is forming clear stratification. The core grain of tungsten blank bar has grown significantly, while the blank edges structure is finer. Observing by SEM image, you can see the internal organization is thick and has high degree crystallinity. But the edge organizations of tungsten blank are showing particle characteristics and organization is small. What’s more the crystallinity has low degree.

To employ electron probe microanalysis on the fracture surface of tungsten blank bar which is after ground and polished and t has obvious delamination phenomenon. Form the edge to the line of the core of tungsten blank bar, we can see, there are the tungsten blank which has delamination phenomenon the ingredients may also different. At the junction of the two layers, the higher rare earth content, the structure is coarser. On the other hand, fine structure has low rare earth content. And the reason may be because sintering process operates at flowing hydrogen atmosphere. The hydrogen will take the heat for the surface of tungsten blank bar away, so that the surface temperature of the blank is lower, and the center temperature is higher, so there is a temperature gradient in a radial direction of tungsten blanks. Rare earth at this temperature gradient effect diffusion and migration is faster, especially when high temperatures are very high, and migration of rare earth is quickly. While at higher temperatures, the sintered degree of tungsten electrode also increased. The area has large rare earth content will hinder the tungsten grain growth and the effect is large. Low rare earth content area the effect is smaller. For the central area, the lower rare earth content, but has high temperatures, then in this region tungsten powder will preferentially to form coarse crystal grains. For the edge region, there has lower rare earth content, and the temperature is low, so only sintered to a higher temperature this part can be fully sintered. The junction of these two regions has high rare earth content, so there are large hinder effect on grain growth, and the temperature range is between these two area, so that the combined effect making the grains in this area is relatively small, which is similar to edge are. In view of this conclusion is the premise of tungsten is good conductor of heat and has fast heat conduction.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com