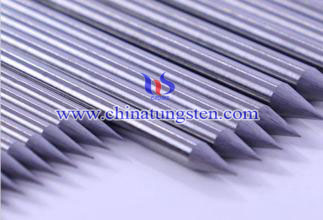

Rare Earth Affected Tungsten Electrode Sintering Process

- Details

- Category: Tungsten Information

- Published on Thursday, 26 May 2016 19:51

The content of rare earth in tungsten powder at sintering process will affect tungsten electrode sintering temperature and density. And the main reason is due to the dispersal of rare earth in sintering process. As we know, with increasing of rare earth content, the influence of rare earth on tungsten grain is increase. On the one hand, rare earths under heat effect will have diffusion migration occur, and resulting in the distribution of rare earth on tungsten powder is uneven. On the other hand, there is hindered effect of rare earth on tungsten grains growing. So containing large rare earth area sintering is more inadequate. On the contrary, the area where has small rare earth content can completely be sintered. And this is the reason that tungsten grain size has large difference. And part of pores is blocked, resulting in density to reduce. Causing by heat effect the rare earth unevenness will be more severe, and the sensitivity of the process is also more obvious.

One of performance of process sensitivity is forming clear stratification. The core grain of tungsten blank bar has grown significantly, while the blank edges structure is finer. Observing by SEM image, you can see the internal organization is thick and has high degree crystallinity. But the edge organizations of tungsten blank are showing particle characteristics and organization is small. What’s more the crystallinity has low degree.

To employ electron probe microanalysis on the fracture surface of tungsten blank bar which is after ground and polished and t has obvious delamination phenomenon. Form the edge to the line of the core of tungsten blank bar, we can see, there are the tungsten blank which has delamination phenomenon the ingredients may also different. At the junction of the two layers, the higher rare earth content, the structure is coarser. On the other hand, fine structure has low rare earth content. And the reason may be because sintering process operates at flowing hydrogen atmosphere. The hydrogen will take the heat for the surface of tungsten blank bar away, so that the surface temperature of the blank is lower, and the center temperature is higher, so there is a temperature gradient in a radial direction of tungsten blanks. Rare earth at this temperature gradient effect diffusion and migration is faster, especially when high temperatures are very high, and migration of rare earth is quickly. While at higher temperatures, the sintered degree of tungsten electrode also increased. The area has large rare earth content will hinder the tungsten grain growth and the effect is large. Low rare earth content area the effect is smaller. For the central area, the lower rare earth content, but has high temperatures, then in this region tungsten powder will preferentially to form coarse crystal grains. For the edge region, there has lower rare earth content, and the temperature is low, so only sintered to a higher temperature this part can be fully sintered. The junction of these two regions has high rare earth content, so there are large hinder effect on grain growth, and the temperature range is between these two area, so that the combined effect making the grains in this area is relatively small, which is similar to edge are. In view of this conclusion is the premise of tungsten is good conductor of heat and has fast heat conduction.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com