Effect of Scandia on Tungsten Oxide Powder Reduction Process(a)

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 17:18

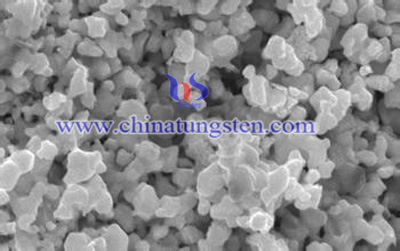

Scandia doped tungsten powders were prepared by spray drying combined with two-step hydrogen reduction. The particle size of doped tungsten powder, powder morphology and doped tungsten matrix were characterized by scanning electron microscope, X-ray diffraction and laser diffraction particle size analyzer, respectively. The reduction behavior of Sc2O3 doped tungsten oxide and the effect of Sc2O3 onthe property of tungsten powder were studied by the temperature programmed reduction. The experimental results showed that the precursor powders prepared by spray drying had spherical shape. The addition of Sc2O3 could decrease the reduction temperature of tungsten oxide. The scandia doped tungsten powder had sub-micrometer size in the range of 0.1 to1 μm and scandium distributed evenly in thepowder. By using this kind powder, sub-microstructure cathode matrices with semispherical grains and homogenous distribution of scandium were obtained.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Nanorods

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 17:14

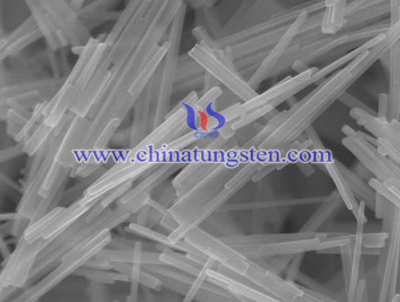

Tungsten oxides nanostructures have exhibited application perspectives in such fields as electrochromic (EC) device, photocatalysis, gas sensing, adsorption of organic dyes, etc. So far, in most high-temperature-reaction fabrications of the tungsten oxide nanostructures, the reactant sources and the substrates are separated. Occasionally, tungsten oxide nanostructures are grown directly from the metallic tungsten, which serves as both the reactant source and the substrate. Liu et al. obtained tungsten trioxide (WO3) nanowires by heating a thin W filament in vacuum with some air leakage. Quan et al. developed a single-step route for the direct growth of monoclinic WO3 nanobelt arrays by heating a W sheet without additional catalysts or reactants. The advantages of this direct heating method include short fabrication time, convenient manipulation, less expensive instrumentation and easy accession to high reaction temperatures. Most importantly, tungsten oxide nanostructures can grow directly from, instead of depositing on, the substrates. Therefore, a number of desired properties, such as good adhesion and low contact interface resistance, can be expected.

As previously reported, in this laboratory a fast heating chemical vapor deposition (CVD) system was developed, in which the temperature of the carbon substrate could be raised to 1800°C in 15 seconds with the passage of large electric current. Combined structures of conical carbon fiber and carbon nanotube (CCF/CNT), which had large length, good straightness and perfect crystallinity, were fabricated using this system. Recently, tungsten oxide nanostructures were also attained with similar instrumentation. This paper describes the fabrication process, characterization and field emission properties of these tungsten oxide nanostructures. In terms of heating uniformity, a Wfilament is apparently more controllable than a W foil when used as the directly heated substrate. However, since some applications, e.g., field emission and dye adsorption, require relatively large-area arrays of tungsten oxide nanostructures, W foils were deliberately used in this work.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Composition Effect on Ultrafine Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 17:10

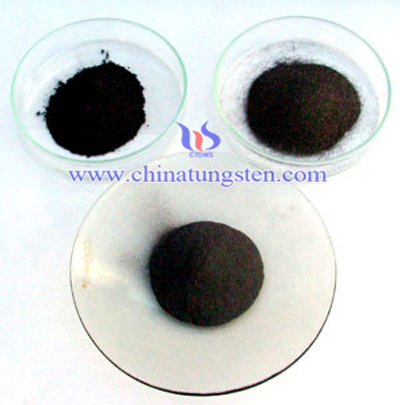

Tungsten oxide, WO3, is a chemical compound containing oxygen and the transition metal tungsten. It is obtained as an intermediate in the recovery of tungsten from its minerals.Tungsten ores are treated with alkalis to produce WO3. Further reaction with carbon or hydrogen gas reduces tungsten trioxide to the pure metal.

The effect of phase composition o f tungsten oxide on the homogeneity of ultrafine tungsten powder has been studied using a conventional hydrogen reduction technique. The results show that ultrafine and homogeneous tungsten powder can be produced from sing le-phase tungsten oxide. The tungsten powder made by multi-phase oxides may be fine , but not homogenous due to differences between the reduction rates ( or reduction paths) of various oxides.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Trioxide Hydtates

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 17:06

Tungsten oxide, also known as tungsten trioxide or tungstic anhydride, WO3, is a chemical compound containing oxygen and the transition metal tungsten. It is obtained as an intermediate in the recovery of tungsten from its minerals.Tungsten ores are treated with alkalis to produce WO3. Further reaction with carbon or hydrogen gas reduces tungsten trioxide to the pure metal.

Tungten trioxides and tungsten trioxide hydrate were synthesized via mixing tungsten with H2O2 in a water bath. Samples were characterized by X-ray diffraction, X-ray photoelectron spectroscopy, cyclic voltammetry. The UV-visible photo activity was ebaluated through the photo degradation of methyl orange in aqueous solution. The effects of photoreaction conditions on the photo activity of the obtained samples introduce in detail. Cyclic voltammetry measurements showed that WO3·0.33H2O, WO3·H2O and WO3 have different oxidation-reduction potential, that lead to a higher conductive band of WO3·0.33H2O than H/H2. The experimental indicanted that photoactivity of WO3·0.33H2O was deeply related with the crystal structure and energy band structure.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Microstructure and Electrochromic Properties of Tungsten Oxide Thin Films

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 17:00

Tungsten oxide thin films were produced by reactive sputter deposition which is an advantageous method because of the opportunity to influence the properties of the films by several parameters. This work focuses on the influence of the oxygen content during the sputtering process and on mixed tungsten and molybdenum oxide films. The oxygen content has a great influence on the film growth velocity and leads to significant differences in crystal symmetry as a function of oxygen partial pressure. Additionally an influence of oxygen content on the gasochromic behaviour was observed. The mixed tungsten molybdenum oxide thin films show no change in the velocity of the gasochromic colouration but the fact that the coloured films show high absorption all over the visible region of the optical spectrum is a significant advantage.

In order to improve electrochromic properties of tungsten-oxide (WO3) thin film, polyethylene glycol (PEG)-doping WO3 films are prepared by peroxopolytungstic acid sol-gel method. Microstructure, optical and electrochiromic properties of the films by X-ray diffraction, spectral ellipsmetry, ultraviolet-visible spectrophotometer and cyclic voltammetry, respectively. The PEG-doping tungsten oxide films contain nanocrystalline / amorphous nanostructure, which facilitate ions transport in the films.Compared to pure WO3 film, the PEG-WO3 film possesses wider spectral modulation, higher coloring efficiency, good electrochromic reversibility and cyclic stability.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Gradient Tungsten Carbide Cutting Tools Characteristics

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 09:38

Gradient tungsten carbide cutting tools can be seen as a kind of coated tungsten carbide cutting tools, but can be seen as an extension of the coated substrate gradient of research. Surface coated with a thin layer of tungsten carbide cutting tools with high hardness wear-resistant coating material, can greatly improve the tungsten carbide cutting tools and service life. However, due to the large difference in thermal expansion coefficients of each phase and thermal stress, it is easy to appear in the phase boundary coating flaking or cracking phenomenon. In order to prevent the crack from the surface of the material to expand and cause substrate failure, the matrix may gradient processing to continuously varying composition gradient instead of abrupt interface, eliminate the mutations physical properties, the thermal stress is minimized. Since it may well absorb the energy of the crack propagation, which can effectively prevent the crack to the inside of alloy expansion, improve the performance of cemented tungsten carbide cutting tools.

To get good performance gradient tungsten carbide coating product, in addition to selecting the coating material and control the coating process, the preparation of gradient alloy matrix is a very critical issue. Cobalt-rich alloy substrate surface with a gradient structure can improve the coating cutting edge strength, improve the coating resistance to crack propagation capacity, improve the flexural strength substrate and coating bond strength and the gradient of tungsten carbide cutting tools.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Profile

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 09:36

With the development of industry, the use of increasingly difficult materials for processing efficiency requirements are also rising. Development of tungsten carbide cutting tools have a direct impact on improving productivity and processing quality. Material composition and structure as well as the geometry is to determine the performance of the three elements of tungsten carbide cutting tools, tungsten carbide cutting tools material properties which plays a key role.

tungsten carbide is a high hardness, refractory metal tungsten carbides (WC, TiC, etc.) micron-sized powder using Co, Mo, Ni, etc. as a binder and sintering of powder metallurgy products. Its high-temperature high-speed steel tungsten carbide content exceeds allowable cutting temperatures up to 800 ~ 1000 ℃, hardness at room temperature of 89 ~ 93HRA; at 540 ℃ when 82 ~ 87HRA, with the high-speed steel hardness at room temperature (83 ~ 86HRA) identical; 760 ℃ When the hardness of 77 ~ 85HRA, and has good chemical stability, heat resistance advantages. tungsten carbide cutting speed of up to 100 ~ 300m / min, far more than high-speed steel, high speed steel life is several times to several times. More than 90 percent in developed countries and more than 55 percent of the turning cutter tungsten carbide materials are used, the proportion of current use is still increasing. In addition, it is used to manufacture cemented tungsten carbide drills, milling cutters, gear cutters, reamers and other complex tools, tungsten carbide its excellent performance is more occasions alternative to other tool materials, has now become the main tool material one.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Applications of Silver Tungsten Alloy - Electrode Material

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 08:45

Electrode material must be good conductivity and has stable discharge characteristics. Copper electrode good processability, especially processing stability, less prone to arc discharge or the arc discharge transition, in most operations can stabilize the discharge, are widely used.

Graphite electrode machining stability is better, the most prominent feature is a large rough currents can remain stable discharge, and to ensure low loss electrodes, but in finishing, easy to discharge instability occurs, easy to pull arc burns. Silver-copper-tungsten alloys and tungsten electrode material is rarely used, because the price of expensive materials. They are still very stable micro-discharge machining parts, deep grooves and other difficult parts, electrode wear is extremely small, are considered for use in precision machining. Electrode material selection to ensure the quality of the discharge must be stable during processing. Copper copper must be free of impurities, the best hammered.

There are several graphite electrode material classification, such as Amy level, ultrafine grade, ultra-fine grade, fine grade, etc., according to the processing accuracy, efficiency requirements choice. Quality graphite material should be homogeneous, good strength, not easy to produce in the processing of flake. Using different electrode materials for processing should be flexible to deal with electrical pairing parameters in order to achieve stable discharge machining, machining works well, played the purpose of the selected material value.

Now many EDM electrical parameters can be automatically matched according to different combinations of materials processing. Mainly dealing with the electrical parameter pairing current, pulse width, pulse size of the gap. Performance electrode materials according to the appropriate choice of the electrical parameters of materials processing advantages to play, handle the processing of defects.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Nanomaterials

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 March 2015 18:31

Nano-sized materials and products have been used widely in many applications because of their outstanding properties, different from those of the bulk materials. In early investigations into nanotechnology, the arc discharge technique was the first well-developed method used to manufacture nanoproducts, whose growth mechanism was, in particular, the effects of catalysts and the atmospheres on the products were considered to be very important. However, owing to difficulties involved in controlling the manufacturing parameters, the purity and quality of nanoproductssynthesized by arc discharge called for improvement. The inert gas condensation (IGC) system was thus established. Because there are no catalysts or containments, it is considered the cleanest method of producing high-quality products. In this system,metals are first placed in a tungsten or graphite boat and evaporated. The metal vapor is then cooled under an inert gas atmosphereto condense into clusters or nanoparticles.

Although the arc method has a higher production rate than IGC system, the latter produces larger particles. Hence, a modified technique based on the IGC system was developed, in which blowing gases were introduced to obtain finer particles with better particle size distribution.Several evaporation techniques are available, including electrical heating, laser vaporization, arc discharge and plasma arc. For some refractory materials, plasma arc is a promising method owing to its relatively high energy as compared to other heating methods. The use of a nozzle made the plasma arc induced by a modified torch more constricted and concentrated than that induced by a conventional torch. The conventional and modified plasma arc torches. To retain the benefits of both thearc discharge method and the IGC system, a plasma arc is used as the heat source and blowing gas is applied to quench the evaporated materials in this modified system. A simplified manufacturing process that enhances the purity of the as-prepared products is required. Therefore, an effective method, namely, the modified plasma arc gas condensation technique has been proposed.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Coated Tungsten Carbide Cutting Tools Surface Characteristics

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 March 2015 10:18

Since the hardness and wear resistance of tungsten carbide cutting tools better, but poor toughness, can be obtained by the cemented tungsten carbide substrate, using CVD (chemical vapor deposition), PVD (physical vapor deposition), HVOF and other methods, a coating layer wear TiC, TiAlN, A12O3 and other thin layer (5 ~ 12μm), forming a surface coated tungsten carbide cutting tools, so that both high surface hardness and high wear resistance, but also tough matrix, can improve the tool life and processing efficiency.

Coated tungsten carbide cutting tools higher than the matrix hardness and wear resistance, high heat resistance (up to 800 ~ 1000 ℃). Such as hardness at normal temperature for HV2000, at 1000 ℃ still maintain HV1000, without coated tungsten carbide cutting tools fell to HV500. Coated tungsten carbide cutting tools than uncoated tungsten carbide high durability (generally 1 to 3 times increase, high up 5 to 10 times), high cutting speed, feed rate and cutting depth larger. These characteristics determine the coated tungsten carbide cutting tools especially for FMS, CIMS (Computer Integrated Manufacturing System) and other automated processing equipment. Coated tungsten carbide is one of the greatest achievements made in recent years in the field of tungsten carbide is another change cutting tool development.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com