Tungsten oxide and Zinc Oxide Using

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 March 2015 16:46

Tungsten oxide and Zinc oxide used as important functional materials have been widely applied into chromic devices, microsensors, surface acoustic wave (SAW)devices and microfluidic devices. Based on the nanotechnology and advanceddeposition techniques, highly functionalized films with good crystallinity could be grown under the optimized conditions, which have a vital significance on the improvement of the performance of the devices. The tungsten oxide nanocrystals withnovel microstructures have been controllably synthesized assisted by the dual-functional reagents. The sputtered ZnO films have been used to fabricate the SAW devices using the microelectromechanical systems technology, and the high-performance SAW devices have been successfully applied into the sensors and microfluidics.

Hexagonal tungsten oxide nanocrystals with microplate, urchin-like, and microspherical morphologies have been hydrothermally synthesized using ammoniumtartrate (AT). The spherical microstructure changed to a microplate one and the crystalphase was partially transferred from hexagonal WO3 to orthorhombic WO3 when the pH value was reduced from 1.08 to 0.6. Besides the adsorption action of the NH4+ and Na+ ions, the capping effect was reinforced by the hydrogen bonding from the tartrate groups with the increase in the concentration of AT. The optical analysis indicated that the bandgap increased with the decrease in the diameter of the hex-WO3 nanocrystals. The enhancement of the blue emission of the nanocrystals originates from the local intercalation of the Na+ ions and the oxygen defects.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Layer

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 March 2015 16:27

The compounds of comprise tungsten oxide layers which have a base inserted between the metal oxide layers and directly coordinated to tungsten. Unlike the metal chalcogenides employed in intercalation compounds, commercially obtainable H2WO4 may be used as a starting material without any pretreatment such as heat annealing or a preliminary interaction with ammonia.

It has been discovered that tungsten trioxide hydrate or tungstic acid can react with bases to form new compounds having a unique layered structure. The novel composition of matter comprises layered compounds of the formula LWO3 where L is a Lewis base containing nitrogen or oxygen electron donors and selected from the group consisting of 5-membered heterocyclic amines, 6-membered heterocyclic amines, amine oxides, triorganophosphates, phosphine oxides and sulfoxides, the layered compounds being characterized in that L is covalently bound to a tungsten atom in the tungsten oxide layer.

In the compounds, a neutral Lewis base, such as pyridine, is strongly coordinated to a tungsten atom in the manner of a molecular coordination complex, e.g. WCl4 py2. But the compounds of the invention are not molecular coordination complexes, as they possess an infinitely connected two-dimensional layered structure.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Blue Oxide Used to Making Tungsten Metal Powder

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 March 2015 16:27

We have found that tungsten metal powder doped with a fine dispersion of oxide particles can be formed by a wet chemical precipitation method. The doped tungsten metal powder can be used to form sintered tungsten bodies, or the elongated bodies formed by reducing the sintered bodies, having a fine tungsten grain size, and a fine distribution of oxide particles for pinning the grain boundaries.

The doped tungsten metal powder is formed from a tungsten oxide powder, the oxide being known as tungsten blue oxide and having the approximate composition WO3. Tungsten blue oxide powder particles can be formed, for example, by the decomposition of ammonium paratungstate in hydrogen. Such tungsten blue oxide particles are porous, consisting of agglomerates of very small oxide crystals, for example about 0.1 micron. The tungsten blue oxide powder can have an average particle size in the range of about 5 to 80 microns. Preferably, the tungsten blue oxide is milled to provide a uniform fine average particle size of about 2 to 7 microns.

The metallic tungsten powder is doped with an effective amount of the metal oxide to provide a fine tungsten grain size, pin grain boundaries, or improve the thermionic capability in sintered bodies formed from the powder. Tungsten powder comprised of greater than about 5 weight percent of the metal oxide can be sintered to form bars, but the bars are difficult to reduce to elongated rods or wires. The oxide is preferably in a range of about 0.5 to 3 weight percent, more preferably about 1 to 2 weight percent of the metallic tungsten powder.

The tungsten blue oxide powder is doped with a soluble salt solution of at least one of the metals from the group zirconium, hafnium, lanthanum, yttrium, and the rare earth's. A preferred rare earth is cerium. Suitable salt solutions can be formed by dissolving chlorides, oxy-chlorides, oxy-nitrates, or preferably nitrates of the metal in water, or the metal oxides can be dissolved in a hydrochloric, or nitric acid solution. The nitrates are preferred because the hydroxide precipitation products formed from precipitation of the metal nitrates, other than the metal hydroxide, are substantially removed by decomposition during reduction of the tungsten blue oxide. Precipitation products from the other salts that do not decompose during reduction of tungsten blue oxide to tungsten, such as chlorides or oxalates, can be washed from the mixture after precipitation of the hydroxides.

A sufficient concentration of the metal salt is dissolved to provide the desired weight percent of the metal oxide in the tungsten powder. Those skilled in the art can determine the quantity of salt solution needed to mix with the tungsten blue oxide to form a suspension, and the proportion of metal salt to tungsten blue oxide to give the desired weight percent of metal oxide in the tungsten metal powder.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Cutting Fluid Action

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 March 2015 09:34

Tungsten carbide cutting tools fluid plays a huge role in metal cutting machining, it is an important machining process material. Effect of cutting fluid: cleaning, cooling, lubrication, rust-proof.

Cooling effect of cutting fluid: cast metal cutting process cutting fluids, due to the flow properties of the liquid, can be a lot of cutting of tropical cutting zone away, the temperature tungsten carbide cutting tools area is reduced, cooling purposes;

Cutting fluid lubrication: tungsten carbide cutting tools and machining parts, there is a gap between the contact surfaces of the chip, which can penetrate into the cutting fluid to form a lubricating film, played the role of lubrication to reduce friction and increase tool life, increase productivity, improve the surface quality, ensure the machining accuracy of the workpiece, to achieve the best economic benefits;

Cutting fluid can also play a role in cleaning can remove adherent tools, tungsten carbide cutting tools, small chips on the fixture, protect the surface to avoid scratches and Machine Tool;

Rust-proof cutting fluid action: cutting fluid additive has added some rust resistance, and to protect the machine, tungsten carbide cutting tools and workpiece to avoid being around corrosive corrosion, so as to achieve the purpose of rust.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Material Selection

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 March 2015 09:32

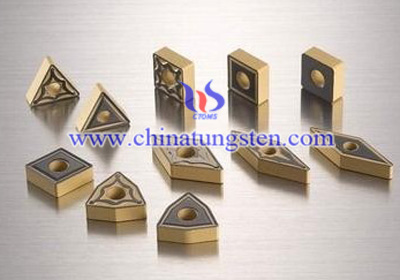

Current product technology from the tool, the tungsten carbide cutting tools gradually replace high-speed steel cutting tools, in particular circular tool. Coated tungsten carbide cutting tools are becoming more common, according to the main chemical components distinguish tungsten carbide cutting tools can be divided into groups based tungsten carbide and titanium tungsten carbide tungsten carbide cutting tools. Including tungsten carbide cobalt-based alloy (YG), tungsten, titanium, cobalt class (YT) and add carbonation rare class (YW) three main components of tungsten carbide (WC), titanium tungsten carbide (Tic), niobium tungsten carbide ( NbC), commonly used metal bonding phase is Co. Tic titanium tungsten carbide tungsten carbide based cemented tungsten carbide is the main component, commonly used metal bonding phase is Mo and Ni.

The correct selection of a suitable cutting tool material, can improve work efficiency, improve processing technology has important significance machinery manufacturing needs. We know that, in addition to cutting tool materials should have the hardness and wear resistance, strength and toughness and economy, the tungsten carbide cutting tools must also meet the following requirements: reliability, high heat resistance and thermal shock resistance, good high temperature mechanical properties and so on. The nature of production, machine type, CNC machining program, the size and shape of the workpiece and the machining accuracy are factors tungsten carbide cutting tools materials processing.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

EDM Parameters of Silver Tungsten Alloy

- Details

- Category: Tungsten Information

- Published on Monday, 23 March 2015 09:17

EDM process parameters can be divided into electrical and non-electrical parameters parameters. The main parameters of the electrical parameters of pulse power is there between processing polarity, pulse width, pulse peak voltage, peak current, and so on. Non-electric parameters are mainly flushing or pumping the way, pressure, flow, carrying knives height, frequency, translational mode, the size of the flat momentum, they influence each other, allelopathy, to select the parameters more difficult.

In order to correctly select the gage EDM parameters to follow, people under the tool electrode material of the workpiece, if the tool polarity, pulse width, peak current, etc. The main parameters of the surface roughness, the discharge gap, ablation rate The four main process indicators affect electrode wear rate and, prior to make technology curve chart, click here to select EDM gage.

EDM machining mold or some parts, usually workpiece material has been previously set, carbon steel, tool steel, stainless steel, nickel-chromium alloy steel of various types of steel material and so can be counted on the EDM, they are is processing performance, process indicators are similar. Including melting point, high vaporization point of tungsten, molybdenum alloys and carbide materials and graphite, copper, tungsten, silver, tungsten sintered materials, conductive polycrystalline diamond, etc. can be counted as another kind of processing power are difficult for them processing materials. Aluminum, zinc, brass and other low melting point of the material, EDM easier. In short, the first step is we analyze the characteristics and technical requirements of the workpiece (eg rough surface, size, tolerance precision) and other technology indicators on the basis of the workpiece material and technical requirements to select the tool electrode materials such as brass, copper, stone or copper tungsten, silver tungsten alloys, of course, to consider whether they are easy to manufacture a tool electrode and the costs and other factors.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Fine Grain Tungsten Carbide Cutting Tools Performance

- Details

- Category: Tungsten Information

- Published on Friday, 20 March 2015 14:11

After the tungsten carbide grain refinement, the hard phase size becomes smaller, the binder phase is more evenly distributed around the hard phase, can increase the hardness and wear resistance of cemented tungsten carbide. Such as the appropriate use of cobalt content, but also to improve the flexural strength and fracture toughness. Mining or drilling for coarse tungsten carbide grains, the average grain size of 4 ~ 5μm; fine grain tungsten carbide cutting tools grades generally used as TY15, YG6 so are grains, the average grain size of 2 ~ 3μm; average grain size of the fine grain tungsten carbide cutting tools for 1 ~ 2μm; submicron grain tungsten carbide for 0.5 ~ 1μm; ultrafine grain tungsten carbide at 0.5μm or less.

Ultra-fine grain tungsten carbide cutting tools grains due to its fine, the blade can be sharpened, smooth; at the same time because of its high strength and hardness, and it could have a long time to maintain a very small edge radius and roughness . Therefore, in the processing of heat-resistant alloy, use YS2, YM051, YM052, YD05 and other ultra-fine grain tungsten carbide cutting tools, than using YT, YG, YW3 class ordinary tungsten carbide cutting tools for better heat resistance and integrated wear resistance.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool Materials Variety Series

- Details

- Category: Tungsten Information

- Published on Friday, 20 March 2015 14:09

After decades of continuous development, the hardness of tungsten carbide cutting tools has reached 89 ~ 93HRA, at a high temperature of 1000 ℃ still has good red hardness, which is several times the durability of high-speed steel cutting tools. tungsten carbide is WC, TiC, TaC, NbC, VC and other refractory metal tungsten carbides and prepared by powder metallurgy from iron group metals as a binder. Compared with the high-speed steel, it has high hardness, wear resistance and red hardness; compared with superhard material, it has a higher toughness. Because of tungsten carbide cutting tools has a good overall performance, so in the tool industry has been widely used.

Diverse types of tungsten carbide cutting tools. In the past, the International Organization for Standardization (ISO) has the tools, tungsten carbide cutting tools are divided into three categories: P class, mainly used for cutting steel; K class, mainly used for cutting cast iron; M class, for the ordinary type tungsten carbide. In recent years, the increasing number of types of processed materials, ISO and the addition to the three types of tungsten carbide, namely H class, mainly for high cutting hard materials such as hardened steel, chilled cast iron; S class for cutting heat materials, high-temperature alloys; N class for cutting non-ferrous metals.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Structures and Optical Properties of Tungsten Oxide Thin Films

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 17:28

The films annealed at 200C and 300 C display violet–red under the sunlight as well as the as-deposited ones. Nevertheless, the film annealed at 400C exhibits transparency and appeared to be blue colored. The film annealed at 200C is amorphous, i.e. does not exhibit diffraction peaks while those annealed at 400C exhibit several sharp diffraction peaks, indicating the crystallization of this film happened. The peaks shown in Figs. 1(b) and 1(c) can be attributed to a mixture of polycrystalline phases, which includes hexagonal h-WO3 phase (JCPDS PDF-33-1387) and triclinic t-WO3 phase (JCPDS PDF-30-1387). It is also seen that the films annealed at 400C were dominated by hexagonal h-WO3 phases. Acosta et al. had prepared the tungsten oxide thin films by sputtering WO3 bulk. Their results indicated that the films mainly contained hexagonal h-WO3 phase and monoclinic α-WO3 phase. Usually, the polycrystalline monoclinic and triclinic phases can be observed in the films deposited by reactive magnetron sputtering from W target, but few reports have also shown the presence of hexagonal phases. we can see that the growths of the film along (002) and (200) orientations of the triclinic phases are enhanced when thermal treatment time at 400C is prolonged from 60 min to 180 min.

Under our experimental conditions, the thickness d of the as-deposited film has been determined to be about 220 nm by an observation of its section SEM. SEM images of the thin films annealed at different temperatures. All the sample films are very compact. The sizes of the sputtered tungsten oxide grains look very uniform and are a little less than 100 nm. The grain boundaries become more and more discernable as the annealing temperature increases from room temperature to 400C, whereas they become very indistinct again owing to the growth of the grains when the annealing time is prolonged from 60 min to 180 min at 400C. This process indicates the structure transformation of the sample films from the complete amorphous nature to crystallization and is in complete agreement with the results confirmed by XRD. The surfaces of the deposited films become rougher as the annealing temperatures rise. When the annealing time at 400C increases from 60 min to 180 min, the nanorod-like structures have grown from the surface of the deposited film. This kind of surface morphology of the samples is very different from those of the films prepared by sol–gel methods and by reactively sputtering tungsten metal target.

It is well known that during the sputtering, the interaction between Ar plasma and WO3 bulk can highly distort and tilt the form works of the WO6 octahedra and thus results in an amorphous film. At the same time, a large number of oxygen vacancies and defects, which can reduce the tungsten ions from W6+ to W5+ or W4+,would be produced in the deposited films. This is responsible for the violet–red color and the amorphous XRD data of the films annealed below 300C. The obvious crystallinity of the deposited films at 400C for 60 min implies that the defects and disordered structures in the films have been effectively activated by this temperature. Consequently, increasing the annealing time at 400C is obviously favorable to the crystallinity and the growth of the films.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Effect of Scandia on Tungsten Oxide Powder Reduction Process (b)

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 17:22

Vacuum electronic devices have a wide application in civil and military fields such as communication, radar and industrial heating. Cathode is an important component in the device since it provides the required electronic beam for the device. Among all the electron emitters, scandate cathodes have aroused great attention among all the cathodes due to their copious emission property.

It has been found in the previous work, the raw powder properties such as morphology, particle size and size distribution greatly affected the emission property of the cathode. The diffusion and distribution uniformity of rare-earth elements would be enhanced if the structure dimension of the emitter decreased from micrometer to sub-micrometer even to nanometer, i.e., the electron emission property of emitter would be improved with the diminution of the micro-structure dimension of cathode matrix.

Scandium oxide doped tungsten powders have been prepared by a new method of spray drying combined with two-step hydrogen reduction. Spray drying has some advantages such as the particle size can be controlled in the single step.

The addition of Sc2O3 shifted the hydrogen consumption peak to the lower temperature side. Namely, the reduction temperature of tungsten oxide decreased with Sc2O3 addition. Adding scandia could decrease the particle size of tungsten. The scandia doped tungsten powder prepared by spray drying method had sub-micrometer size in the range of 0.1μm to1μm in semispherical shape and scandium distributed evenly in the powder. Using scandia doped tungsten powder, sub-micro-structure cathode matrices with semispherical grains and homogenous distribution of scandium was obtained.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com