Tungsten Alloy Scrap(d)

- Details

- Category: Tungsten Information

- Published on Friday, 13 March 2015 09:11

Accelerate the development of "urban minerals"

"Eleventh Five-Year" period, non-ferrous metal industry basically solved the scale of the problem, "1025" period, non-ferrous metal industry specification will mainly solve the problem, continue to become bigger and stronger on the road to sustainable development.

The party's seventh session of the Fifth Plenary Session: To accelerate the construction of resource-saving and environment-friendly society, to improve the level of ecological civilization, and actively respond to global climate change, to develop the loop economy, enhance resource conservation and management. Intensify environmental protection, strengthen ecological protection and disaster prevention and mitigation system, enhance capacity for sustainable development. Non-ferrous metal is "urban minerals" an important part. The State Council issued the "non-ferrous metals industry restructuring and revitalization plan" is also clear: focus their efforts on recycling, vigorously develop the loop economy, accelerate the construction of the whole society, non-ferrous metal recycling system. This fully shows that "1025" period, non-ferrous metal industry promising.

China Nonferrous Metals Industry Association Recycling Metal Branch, the "Eleventh Five-Year" period, non-ferrous metal industry basically solved the scale of the problem, "1025" period, non-ferrous metal industry specification will mainly solve the problem, continue in sustainable development bigger and stronger on the road.

According to regenerate the "Eleventh Five-Year" period of non-ferrous metal industry development momentum in 2015, our main recycled metal production will reach 12 million tons, of which 3.8 million tons recycled copper, 5.8 million tons of recycled aluminum, secondary lead 2.4 million tons, accounting for then the proportion of copper, aluminum, lead production, respectively, 40%, 30%, 40%. Recycled copper, recycled aluminum industry form a group of more than 100,000 tons of large-scale enterprises, the secondary lead industry to form a group of more than 50,000 tons of large-scale enterprises. The top 10 industrial enterprises reached more than 50% concentration, fostered a number of key areas of industry cluster development, which accounted for more than 80 percent capacity.

According to reports, "1025" period, China will further optimize the layout of non-ferrous metal industry. Key support in Zhejiang, Guangdong, Shandong, Tianjin, Jiangxi and other regional development recycled copper, support Guangdong, Zhejiang, Chongqing, Shanghai, Henan and other regional development recycled aluminum, support, Anhui, Henan, Shandong, Jiangsu, Hubei and other areas of development of secondary lead. Meanwhile, in the Pearl River Delta, Yangtze River Delta, Bohai Sea and the Chengdu-Chongqing Economic Zone and other places to support expansion 200,000 tons recycled copper project 6-8, 200,000 tons of recycled aluminum items 8-10. In the north, central, northeast, the Yellow River Delta and other regions to support expansion from 50,000 to 100,000 tons recycled copper project 10, from 50,000 to 100,000 tons of recycled aluminum project 15, more than 50,000 tons Secondary Lead Project 10. Renovation and expansion of local support in the northwest 50,000 tons recycled copper project 2, 50,000 tons of recycled aluminum project 3.

By 2015, China's non-ferrous metal industry as a whole will significantly improve the standard of technical equipment. Dismantling the universal application of mechanization, the use of standards to further improve the classification. Metal recycling facility complete melting furnace and ancillary to the direction of the development, production and advanced technology can reach more than 80%. "1025" period will focus on breakthroughs in the field of renewable non-ferrous metal scrap non-ferrous metal pretreatment, smelting and energy saving technology and key equipment, a key technology to solve a number of metal recycling and energy saving technologies through technology integration and demonstration gradually establish a renewable non-ferrous metal industry, science and technology innovation system.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide cutting tools Welding Process (B)

- Details

- Category: Tungsten Information

- Published on Thursday, 12 March 2015 14:52

Tungsten carbide cutting tools hardness (HRA) is 89 to 94, much higher than the high-speed steel; at 540 ℃ hardness (HRA) is 82 to 87, and the hardness of high-speed steel normal temperature (HRA83 ~ 86) fairly, but also has good chemical stability, heat resistance advantages. The tungsten carbide cutting tools welding include:

4. After welding insulation. After welding insulation is an important process brazed tungsten carbide insulation directly affects the quality of the welds. Greater tendency to crack tungsten carbide (YT class), prohibits the newly welded tool contact with the influx of cold water and ground, nor with acute cold wind. Should generally be slow cooling in quartz sand, asbestos powder or aluminum silicate fiber box, the tool should be densely stacked in an incubator, to the workpiece by a lot of heat insulation and slow cooling.

5. Remove excess flux near the weld will have cooled after welding workpieces into boiling water, then sandblasted, you can completely remove excess weld flux and oxide and other dirt. Under the conditions permit, the workpiece can be placed in the pickling tank for pickling, cold water tank must be cleaned and heat sinks have been pickled.

6. Check the weld seam quality checks after brazing Have been checking out the defective parts, can be re-heated soldering, but it should minimize the number of re-welding, to avoid tungsten carbide cutting tools due to repeated heating and affect the quality. Workpiece cracks have occurred should be removed at the crack of tungsten carbide cutting tools will analyze the causes and re-welded.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide cutting tools Welding Process (A)

- Details

- Category: Tungsten Information

- Published on Thursday, 12 March 2015 14:49

Tungsten carbide cutting tools hardness (HRA) is 89 to 94, much higher than the high-speed steel; at 540 ℃ hardness (HRA) is 82 to 87, and the hardness of high-speed steel normal temperature (HRA83 ~ 86) fairly, but also has good chemical stability, heat resistance advantages. The tungsten carbide cutting tools welding include:

1. welding preparation

Check whether there is oil and other foreign matter tungsten carbide blade, gasoline, alcohol or acetone; by piece check the blade there is no visible cracks, chipping and other defects. In addition to the tool body shape, size and check the knife blade slot is similar, the burr at the sipes must be thoroughly cleaned.

2. Welding

(1) Solder, flux flux solder coating put on the uniform should be coated release, should be filled with solder weld.

(2) Tool and the relative position of the tool sensor and the sensor relative to the unreasonable position, often local overheating, causing the blade, blade crack, it is necessary to control the relative position of the tool and the sensor.

3. Heat the high frequency brazing

When high-frequency heating brazing, soldering temperature and heating rate is the main process parameters affect the quality of welding brazing, heating rate is too high and too fast brazing temperature inside the tool generates great stress, easy to produce welding cracks and crack phenomenon. Low temperature affects the strength of the weld seam of brazing, heating rate is too slow grain growth caused by base metal, metal oxide and other undesirable phenomena. Such as heating too high as to cause evaporation of zinc and manganese oxide solders, causing slag and joint strength loss and other problems; the impact of low solder spreading.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Scrap(c)

- Details

- Category: Tungsten Information

- Published on Thursday, 12 March 2015 09:13

Accelerate the pace of development and utilization

And exploitation of native non-ferrous mineral resources compared to 2010 China Nonferrous Metals Industry renewable energy savings equivalent to 17.19 million tons of standard coal, water and 1.32 billion cubic meters, reducing solid waste emissions 1.16 billion tons, 370,000 tons of sulfur dioxide emissions reduction.

In 2010, a series of favorable policies to encourage the country and demand driven, non-ferrous metal industry enterprises to accelerate investment in fixed assets, fixed assets investment in non-ferrous metals major regeneration species showing a rapid growth trend. On the one hand non-ferrous metal industry leaders continue to expand the existing production scale, on the other hand a number of new large-scale project under construction or have completed and commissioned. With the gradual production of key projects, non-ferrous metal industries in China will significantly increase industry concentration, industry restructuring and will significantly accelerate the pace of industrial upgrading.

Non-ferrous metals scrap recycling equipment research and development of key technologies will achieve a major breakthrough. Renewable resources by China Industrial Technology Innovation Strategic Alliance of National Science and Technology Support Program "typical use scrap metal loop product key technology and application research" project was officially launched in 2010. The project to regenerate the use of high-value, drive chain length, technical standards that require high scrap copper, aluminum easy open cans, scrap wire and cable, scrap metal, scrap tungsten alloy and other typical non-ferrous metal scrap recycling as the main research content the key breakthrough of scrap copper rod directly localization sets regenerative braking technology, easy-open cans relegation scrap reduction techniques, such as 45-55 key technologies developed easy-open cans scrap melting furnace, single roll decomposition of waste electrical utilization equipment, large quantities of small and medium sized bearing wear repair equipment and other key equipment 18-22 kinds to achieve 100% localization of key equipment. Implementation of the project, and will promote the regeneration of non-ferrous industrial upgrading to provide strong scientific support.

In 2010, Tianjin Ziya loop Economic Zone, Anhui Jieshou field camp loop Economy Industrial Zone, Hunan Miluo loop Economy Industrial Park, Guangdong Qingyuan Huaqing loop Economic Park, Ningbo Jintian Industrial Park and other parks selected non-ferrous metal the first national demonstration base mineral city. Yingtan, Jiangxi Copper dismantling Processing Zone, Liaoning (Donggang) Renewable Resources Industrial Park, Guangxi Wuzhou import renewable resources Processing Zone has passed the acceptance of Environmental Protection Department and other departments.

Zhejiang Taizhou metal recycling industry base, Tianjin Ziya loop economy industrial park, west loop renewable resources Lanzhou Industrial Park, Rudong import renewable resources processing zones, Hunan Miluo renewable resource recycling and processing bases, Yinchuan (Ling Wu) Renewable Resources loop economy demonstration areas, Ganzhou in Jiangxi Fengcheng recycled metal distribution market, Hubei Gokseong park renewable resources, recycled metal market Tongliao, Inner Mongolia, Liaoning, Dalian renewable resource loop Industrial Park, Henan Ge day recycled metal markets were in a tight construction. At present, China's imports of renewable resources processing park and the number of regional distribution of renewable resources market has more than 30, the initial formation of the radiation of the import of renewable resources and domestic recycling network system, and will gradually become China's non-ferrous metal industry development of renewable raw materials supply base .

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

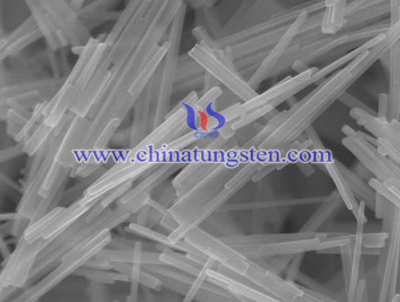

Synthesis of Nanostructured Tungsten Oxide Crystalline Films

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 March 2015 18:40

Over the last decade, nanostructured tungsten oxide materials have attracted much interest due to their potential for catalyst, gas sensors, and electrochromic material applications. Several studies have been conducted by using various techniques, including the oxygen plasma processing, plasma sputtering, chemical solution, sol-gel techniques, electron beam evaporation deposition, electrochemical etching, and the chemical vapor deposition techniques. Most work concerned the synthesis of nanoparticles for catalytic applications based on chemical solution methods.

The nanostructured tungsten oxide materials were synthesized using a simple hot filament CVD technique. The details of the process were described elsewhere in our previous publications. The tungsten filament acted as a precursor for tungsten oxide, and no catalyst or other tungsten-containing compound precursor was used. Both AlN and A ceramic substrates were used. Prior to the experiments, the substrates were ultrasonically washed in the methanol solution for 5 minutes, and dried with helium. After placing the substrate, the chamber was pumped down to Torr and then fed with the Ar gas (purity: 75%) to ambient pressure. During deposition, the gas inside the chamber was in a static state. The distance between the hot filament and substrate remained unchanged. The substrate temperature was controlled by adjusting electrical current on the hot filament, which was different from our previous experiments where the substrate temperature was controlled by simply changing the distance between the substrate and the hot filament.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Method for Forming Tungsten Oxide Films

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 March 2015 18:36

A method is disclosed for forming a tungsten oxide film on a substrate by applying an alkyl amine tungstate compound thereon and removing at least a portion of the alkyl amine tungstate compound to form a tungsten oxide film.

In a preferred embodiment, a solution of alkyl amine tungstate compound is formed in a solvent to uniformly apply the alkyl amine tungstate compound; the solvent is removed by evaporation thereby forming a deposit; the deposit is heated for a time and at a temperature sufficient to at least partially pyrolyze the alkyl amine tungstate compound.

The alkyl amine tungstate compound desirably may be selected from the group consisting of bis (di-n-octylammonium) tetratungstate, and di (n-octadecylammonium) tetratungstate. Preferably, bis (di-n-octylammonium) tetratungstate is used.

The invention also provides tungsten oxide films which include suboxides of tungsten oxides (WO3); which have an average ratio of oxygen atoms to tungsten atoms equal to or less than 3:1; which are denser than films produced from currently known MOD precursor compounds; which have a color gradient, that is, regions of different color; and wherein the regions of color are electrochromic.

A method for forming a tungsten oxide film comprising the steps of:

a) applying onto an ITO coated substrate a solution containing an alkyl amine tungstate compound dissolved in 50:50 2-propanol:xylene solvent,

b) vaporizing said 50:50 2-propanol:xylene solvent from the applied solution to produce a deposit on said ITO coated substrate composed predominately of said alkyl amine tungstate compound, and

c) heating the deposit in the presence of an oxygen containing atmosphere for a time between about 20 and 25 minutes and at a temperature between about 450° C. and 510° C. to decompose said alkyl amine tungstate compound to produce a tungsten oxide film which in a reduced state has a transmittance between 800-1200 nm which is less than 25 percent and which in an oxidized state has a transmittance between 400-1200 nm which is greater than 80 percent.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Synthesis of Nanostructured Tungsten Oxide Thin Films

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 March 2015 18:32

Several methods are used to form tungsten oxide films. The methods include sputtering, chemical vapor deposition, and plasma enhanced chemical vapor deposition, in which sub-atmospheric pressure must be maintained. In these methods, large, complex and expensive equipment is needed, and the methods involve significant energy consumption and relatively high operating costs. The films produced by current methods are tungsten oxide films of WO3, without suboxides, and which are colorless or faint yellow, single color films.

A facile and inexpensive method to produce thin films of nanostructured tungsten oxide is described. A nanocrystalline tungstite (WO3·H2O) film is spontaneously formed when a tungsten substrate is immersed in nitric acid at elevated temperatures. The resulting thin film is composed of plate-like tungstite crystals with edges preferentially directed out from the substrate surface. The tungstite can easily be transformed into WO3 by annealing. Patterned WO3·H2O/W structures can be obtained by a combination of lithographic techniques and etching. In this study, the effect of exposure time, acid concentration, and temperature on the microstructure of the films has been investigated. The potential of this inexpensive synthesis method to produce large-area coatings of nanostructured tungsten oxide as well as patterned films makes it interesting for several different applications, such as batteries, gas sensors, and photocatalysts.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

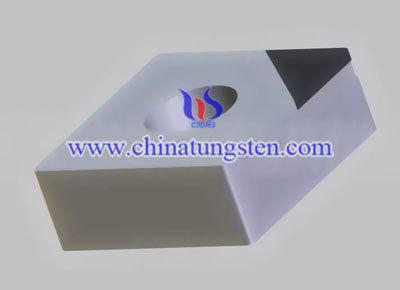

Coated Tungsten Carbide Cutting Tools Dry Cutting Technology

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 March 2015 11:19

Tungsten carbide cutting tools surface coating technology in recent decades in response to market demand developed surface modification technology, which effectively solve the contradiction tool material hardness, wear resistance and strength, toughness between more effectively improve the life of tungsten carbide cutting tools, the tool to obtain excellent mechanical properties, and greatly improve the machining efficiency, is widely recognized as the ideal tool material speed cutting, dry cutting technology.

Dry cutting technology is a major innovation of traditional production methods, is a new clean manufacturing technology. All kinds of super-hard, high temperature materials and coating technology development tool, created extremely favorable conditions for dry cutting technology. Coated tungsten carbide cutting tools dry coating technology has become an effective way to dry machining. Dry cutting tungsten carbide coatings play a role in the following two main aspects: on the one hand, tungsten carbide coating has a thermal conductivity than the matrix tool and workpiece material is much lower, thus weakening the thermal effect of the tool substrate ; on the other hand, it can effectively improve the friction and adhesion of the cutting process, thereby reducing the cutting heat generated.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

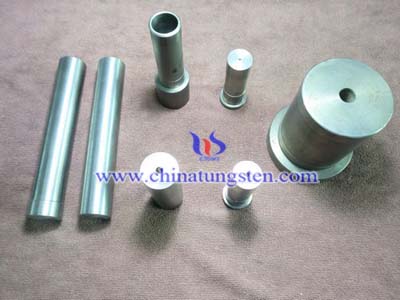

Tungsten Carbide Cutting Tools Brazing Equipment

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 March 2015 11:17

Brazing of tungsten carbide cutting tools with high hardness and wear resistance, especially at high temperatures can still maintain its high hardness, has been widely used in manufacturing various metal cutting tools. Brazed tungsten carbide is firmly connected to one of the most successful method for steel substrates, but the tungsten carbide cutting tools welding technology is an important factor in causing weld cracking.

Brazed tungsten carbide cutting tools mainly for its simple and compact structure, good rigidity, greater flexibility in use, adaptability and other characteristics, are used in precision machining, FMS, and other various metal cutting machining. Brazed tungsten carbide cutting tools are mainly using high-frequency welding brazing equipment. Induction brazing by induction heating to provide heat, or working through the induction coil is energized rather than directly on the tungsten carbide cutting tools, electrical energy transfer by induction method to tungsten carbide cutting tools, and selectively heating the surface of the part to be welded to the brazing A method of soldering temperature. Equipment brazed tungsten carbide welding process used by high-frequency induction heating equipment, high frequency induction brazing machinery and water cooling system and control system.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Scrap(b)

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 March 2015 08:47

At present, China recycled metal production has maintained rapid growth for 10 consecutive years, renewable resources, recycling more than 40,000 companies, employing nearly 1,000 people, recyclables dismantling converted more than 5,000 enterprises, more than 640 distribution market. In recent years, mainly recycled metal production average annual growth of 27%, from 720,000 tons in 2000 to 7.75 million tons in 2010. By the end of 2010, non-ferrous metal has become an important part of the China Nonferrous Metals Industry, vigorously develop renewable non-ferrous metal industry, effectively easing the shortage contradiction Chinese native nonferrous mineral resources.

According to estimates, compared with the primary metal production, per ton recycled copper, recycled aluminum, secondary lead is equivalent to saving 1054 kg respectively 3443 kg, 659 kg of standard coal, water and 395 m3, 22 m3, 235 m3, reduce solid waste discharge 380 tons, 20 tons, 128 tons, recycled copper per ton, respectively, equivalent to reducing emissions of sulfur dioxide Secondary Lead 0.137 tons, 0.03 tons.

According to the China Nonferrous Metals Industry Association Recycling Metal Branch, at present, China's non-ferrous metal industry is regenerated important juncture in the restructuring, and already has a good industrial base: First, a significant effect of renewable non-ferrous metal industry restructuring, recycled metal processing park construction gradually scale, enterprises have developed rapidly, smelting and processing technology and equipment to improve the standard of significant technological progress and innovation to accelerate, formed from the scrap metal recycling, dismantling, smelting, processing and product applications complete industrial chain; the second is non-ferrous metal Product applications expanding renewable broad application prospects aluminum, secondary lead alloys, recycled copper industry has achieved good results; Third, private enterprises accounted for the main production of renewable non-ferrous metals, with mechanism of living, a new system, a strong sense of innovation and other advantages, to promote metal recycling industry has made important contributions; four is recycled metals industry has always been attached great importance to the national authorities and strong support, the current form of production, research and universities work together to promote industrial development efforts.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com