Electrochromic Devices Based on Porous Tungsten Oxide Thin Films

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 March 2015 18:18

Tungsten oxide (WO3) has been one of the most widely studied materials due to its multifunctional properties that have wide spectrum of applications in electrochromic devices, catalysers, gas sensors, optical switching devices, and so forth. Over the past three decades, intensive research has been carried out towards improving WO3-based electrochromic (EC) devices due to their important energy saving properties. A typical asymmetric EC device consists of an ion conducting (IC) layer, which also acts as a counter electrode and a WO3 electrochromic layer as the working cathode, sandwiched between two transparent conductive electrodes (TEs). When a low voltage (1–3 V) is applied across the TEs, Li+ ions from the counter electrode and electrons (e−) from the TE move to the EC WO3 layer. This double injection results in the formation of colored LixWO3 bronzes, with a controllable degree of coloration as a function of (Li ion concentration). When the applied voltages are reversed, leading to a bleached state.

Recent developments in the synthesis of transition metal oxides in the form of porous thin films have opened up opportunities in the construction of electrochromic devices with enhanced properties. In this paper, synthesis, characterization and electrochromic applications of porous WO3 thin films with different nanocrystalline phases, such as hexagonal, monoclinic, and orthorhombic, are presented. Asymmetric electrochromic devices have been constructed based on these porous WO3 thin films. XRD measurements of the intercalation/deintercalation of Li+ into/from the WO3 layer of the device as a function of applied coloration/bleaching voltages show systematic changes in the lattice parameters associated with structural phase transitions in LixWO3. Micro-Raman studies show systematic crystalline phase changes in the spectra of WO3layers during Li+ ion intercalation and deintercalation, which agree with the XRD data. These devices exhibit interesting optical modulation (up to ~70%) due to intercalation/deintercalation of Li ions into/from the WO3layer of the devices as a function of applied coloration/bleaching voltages. The obtained optical modulation of the electrochromic devices indicates that, they are suitable for applications in electrochromic smart windows.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Electrochromic Properties of Tungsten Oxide Films Prepared

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 March 2015 18:10

WO3-x thin films were deposited on induim tin oxide (ITO) glass substrates with various oxygen flow ratios from 0.55 to 0.7 by the reactive facing-target sputtering method, at a power density of 4 W/cm2 and room temperature. The structural properties of the WO3-x thin films were measured by X-ray diffractometry and Raman spectral analysis. As-deposited WO3-x thin films had an amorphous structure. In the Raman spectra, WO3-x thin films exhibited two strong peaks at 770 and 950 cm-1 attributed to the vibrations of W6+–O and W6+=O bonds, respectively. The electrochemical and optical properties of WO3-x thin films were measured by cyclic voltammetry and UV/vis spectrometry. The results showed the highest charge density at an oxygen flow ratio of 0.7 and the highest transmittance in the visible range. The maximum coloration efficiency was 30.82 cm2/C at an oxygen flow ratio of 0.7.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Electrochromic Tungsten Oxide Film Deposition

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 March 2015 18:04

Tungsten trioxide (WO3) has been studied for many years. It is one of the best materials for use in the fabrication of electrochromic (EC) devices, such as electrically tintable glass for use in buildings and automobiles. WO3 has the desirable characteristics of transparency, chemical stability—as in the stoichiometry doesn't change with time after deposition—and relatively low cost. Typically, WOx, where 3>x>2.75, is desired for the EC application for the following reasons: (1) in the x>3 region, the oxygen is rich such that the WOx film may not be bleachable after lithium atom insertion; and (2) in the region x<2.75, the film is no longer transparent.

The deposition of WO3 films is of considerably interest, not least because of their electrochromic properties. Physical vapor deposition (PVD) is one of the conventional methods used for depositing EC films. During the Physical Vapor Deposition (PVD) WOx deposition, the stoichiometry of the film (value of x) is controlled by the oxygen partial pressure. However, the value of x changes with the oxygen partial pressure too sharply such that it is very hard to control in the range of interest—see FIG. 1; in addition, the deposition rate is very low. See T. J. Vink, E. P. Boonekamp, R. G. F. A. Verbeek and Y. Tamminga, Lithium trapping at excess oxygen in sputter-deposited a-WO3 films, Journal of Applied Physics 85(3), pp. 1540-1544, 1 Feb. 1999. According to Vink et al.'s data, reproduced in FIG. 1, control of the oxygen partial pressure to achieve an O/W ratio (value of x) of around 2.85 is very difficult due to the rapid change of x with oxygen partial pressure—such a process would have a very narrow process window and consequently would likely be a process with poor yield.

The two factors—narrow process window and low deposition rate—make the prior art PVD WOx film deposition process unattractive for use in the EC industry. Clearly, there is a need for improved deposition methods which provide sufficient control of the x value to allow high yield deposition of EC WOx films with x in the desired range of 3>x>2.75. Furthermore, there is a need for a deposition method for these EC films which provides a high enough deposition rate to satisfy manufacturing throughput targets at relatively low cost.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Cobalt Leaching

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 March 2015 11:14

In the process of grinding fluid grinding tungsten carbide cutting tools can not only reduce the grinding temperature, but also serve to improve the quality of grinding and grinding efficiency effects, and therefore widely used in the processing. But when grinding tungsten carbide grinding fluid is possible to make use of tungsten carbide cobalt leaching. tungsten carbide cobalt binder material, it will greatly reduce the life of the leaching of tungsten carbide cutting tools; at the same time, high levels of cobalt grinding waste will pollute the environment, workers' health hazard. Therefore, the study of the mechanism of grinding tungsten carbide cutting tools cobalt leaching when looking for an effective way to reduce or avoid leaching of cobalt tool, has great significance.

To reduce the wear of tungsten carbide cutting tools, cutting tools to avoid leaching of cobalt element, reduce environmental pollution, to achieve green manufacturing, through the development of triethanolamine alternatives to inhibit leaching effect of grinding fluid cobalt, or use the mill containing triethanolamine After cutting fluid grinding tungsten carbide, tungsten carbide debris should be promptly separated from the grinding waste and avoid leaving a long soak cobalt leaching.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Coated Tungsten Carbide Cutting Tool Wear Factors

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 March 2015 11:12

Tungsten carbide is WC, TiC, TaC, NbC, VC and other refractory metal tungsten carbides and prepared by powder metallurgy from iron group metals as a binder. The tungsten carbide cutting tools are mainly TiN coating, ZrN coating, TiCN coatings, tungsten carbide cutting tools and wear resistance of the coating with many factors.

1. At low load, tungsten carbide substrate, TiN coating, ZrN coating close to the coefficient of friction, coefficient of friction when the TiCN coating at a certain range of values, TiCN coating surface to generate a more complex compound when the friction acts as a lubricant, so that friction coefficient decreases. With friction continues, the surface of the material occurs micro peeling, friction coefficient return to a normal state.

2. Tungsten carbide cutting tools coating at high speed and high load, low coefficient of friction than the load at low speed. This is because at low speed low load, the friction balls and the sample mainly localized mainly microparticles intermittent mechanical shock, will result in the coating peeling off, wear debris of these fine grains, high hardness, hindered and sliding friction of the sample, causing friction coefficient; and under high pressure, the contact surface friction increase participation and improve the wear surface was in contact stiffness, friction is converted to mechanical friction, the friction coefficient is relatively lower.

3. Wear Mechanism tungsten carbide cutting tools coated abrasive wear, friction under high load high speed state, the lowest friction coefficient ZrN coatings, friction best performance. Because the tool is often used for high-speed cutting tool material for this performance has very important significance.

4. Tungsten carbide coated with the coating hardness wear Obviously, microstructure has a close relationship, the higher the hardness, the more uniform coating of dense tissue microstructure, wear the better.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Scrap(a)

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 March 2015 08:44

With the acceleration of industrialization and urbanization in China, the major non-ferrous metal production and consumption of the rapid growth of non-ferrous metal resources gap is growing. Currently external dependence of copper, aluminum, lead and zinc mineral raw materials were 60%, 50%, 40% and 15%. Non-ferrous metal industry has become the bottleneck of resources and the environment to break an important industry, non-ferrous metals in effectively alleviate the tension between supply and demand, improve resource utilization efficiency, and promote the sustainable development of society has an important role. Meanwhile, non-ferrous metal products industry wide relevance, absorptive capacity and strong employment, capital and technology-intensive industries has broad prospects for development.

Promising sunrise industry

Non-ferrous metal industry has an important trend in the development of non-ferrous metal loop recycling good performance, non-ferrous metal recycling significant energy saving effect is.

Non-ferrous metals is an important basic raw material industry in the national economy. It has a good loop recycling performance. In 2010, China's imports of major physical volume of ferrous scrap is 7.21 million tons, of which 4.36 million tons of copper scrap, aluminum-containing waste 2.85 million tons, copper, aluminum, lead metal content of domestic recycling 405 tons, of which copper 1.1 million tons, 1.6 million tons of scrap, lead scrap 1.35 million tons, greatly ease the contradiction between supply and demand of China's non-ferrous metal resources, and reducing the exploitation of native minerals.

At the same time, in 2010, China's non-ferrous metal production reached 7.75 million tons major regeneration. Of which 2.4 million tons recycled copper, recycled aluminum 4 million tons, 1.35 million tons of secondary lead. And exploitation of native non-ferrous mineral resources compared to 2010 China Nonferrous Metals Industry renewable energy savings equivalent to 17.19 million tons of standard coal, water and 1.32 billion cubic meters, reducing solid waste emissions 1.16 billion tons, 370,000 tons of sulfur dioxide emissions reduction.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Hydrates Crystallites

- Details

- Category: Tungsten Information

- Published on Monday, 09 March 2015 17:49

The past couple of decades have witnessed an exponential growth of activities in this field worldwide, driven both by the excitement of understanding new science and by the potential hope for applications and economic impacts. The largest activity in this field at this time has been in the synthesis of new nanoparticles of different sizes and new shapes. Besides giving us new properties, creating novel nanostructures requires new understanding of the properties of their surfaces, which has been in the center of attentions from many scientific researchers. As one kind of well-known semiconductor materials, tungsten oxide and its hydrates (WO3•nH2O, n=0~2) have been extensively researched and employed in various application fields. Because many of their nanostructures and morphologies are inextricably bound to properties in several fields, scientists have been concentrating on the research of the preparation of micro/nanostructures of these materials. However, there still remains further investigations on the exploration of developing facile, green and economical techniques when controlling these interesting promising structures, which are believed to be very necessary for expanding the application fields of tungsten oxide hydrates materials. In this dissertation, a facile hydrothermal technique has been developed to prepare micro/nanostructured tungsten oxide hydrates materials (particles and films) with/without the assistant of templates and microwave heating. The following are the main results and conclusions:

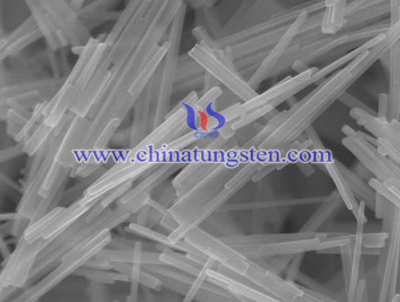

Tungsten oxide hydrates crystallites with a diversity of phases and morphologies were successfully controlled by using tungsten powders as starting materials via a facile and additive-free hydrothermal process. Various micro/nanostructures of products, including cubic blocks, “snowflakes”, round angular blocks, hexagonal “gears”, cuboid rods, hexagonal plates and nanoflakes,were obtained by simply changing the reaction conditions. Results show that the nucleation, crystallization and diffusion of the growth units were found to play key roles in different conditions to vary the products phases and morphologies.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Hydrothermal Synthesis of Tungsten Oxide Nanostructures

- Details

- Category: Tungsten Information

- Published on Monday, 09 March 2015 17:46

Tungsten oxide, also known as tungsten trioxide or tungstic anhydride, WO3, is a chemical compound containing oxygen and the transition metal tungsten. It is obtained as an intermediate in the recovery of tungsten from its minerals.Tungsten ores are treated with alkalis to produce WO3. Further reaction with carbon or hydrogen gas reduces tungsten trioxide to the pure metal.

Tungsten oxides inorganic semiconductor materials have received considerable attention in recent years because of their unique physico-chemical properties and widespread applications in various areas,such as electrochromic ( EC ) devices,gas sensors,photocatalytic systems,photoelectrochemical devices,and so on.Recently hydrothermal method has been exploited for the preparation of tungsten oxide micro / nanostructures with different sizes and shapes. Combining with our group' s work on the preparation of tungsten oxide micro /nanomaterials,the progress of preparation of tungsten oxide micro / nanomaterials by hydrothermal method is presented. The key influencing factors,such as the choice of reagents,the reaction time and temperature,are discussed in detail. The development trends of the tungsten oxide micro / nanomaterials fabricated by hydrothermal method are also proposed.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Synergistic Effect Between Ceria and Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Monday, 09 March 2015 17:42

WO3–CeO2–TiO2 catalysts for NO (nitrogen monoxide) reduction by ammonia were prepared by a sol–gel method. The catalysts were characterized by BET, XRD, Raman, NH3/NO adsorption and H2-TPR to investigate the relationships among the catalyst composition, structure, redox property, acidity and deNOx activity. WO3–CeO2–TiO2 catalysts show a high activity in a broad temperature range of 200–480 1C. The low-temperature activity of catalysts is sensitive to the catalyst composition especially under low-O2-content atmospheres. It may be related to the synergistic effect between CeOx and WOx in the catalysts. On one hand, the interaction betweenceria and tungsten oxide promotes the activation of gaseous oxygen to compensate the lattice oxygen consumed in NH3-SCR (selective catalytic reduction) reaction at low temperatures. Meanwhile, the Br nsted acid sites mainly arise from tungsten oxides, Lewis acid sites mainly arise from ceria. Both of the Br nsted and Lewis acid sites facilitate the adsorption of NH3 on catalysts and improve the stability of the adsorbed ammonia species, which are beneficial to the NH3-SCR reaction.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Film

- Details

- Category: Tungsten Information

- Published on Monday, 09 March 2015 17:37

In the past few years, an increasing interest has been put on the tungsten oxide films due to their potential applications in smart windows, gas sensors, photocatalytic reactions, and optoelectronic devices etc. The unique properties of the tungsten oxide films were usually determined by the oxygen defects and the valence states of tungsten ions. Besides, it is very important to improve the properties of tungsten oxide films and other oxide films by controlling their morphologies and crystalline phases, which mainly depend on the preparation technologies and thermal treating temperatures and atmospheres.

Tungsten oxide thin films were deposited on glass substrates by the magnetron sputtering of WO3 bulk at room temperature. The deposited films were annealed at different temperatures in air. The structural measurements indicate that the films annealed below 300 C were amorphous, while the films annealed at 400 C were mixed crystalline with hexagonal and triclinic phases of WO3. It was observed that the crystallization of the annealed films becomes more and more distinct with an increase in the annealing temperature. At 400C, nanorod-like structures were observed on the film surface when the annealing time was increased from 60 min to 180 min. The presence of W=O stretching, W–O–W stretching, W–O–W bending and various lattice vibration modes were observed in Raman measurements. The optical absorption behaviors of the films in the range of 450–800 nm are very different with changing annealing temperatures from the room temperature to 400C. After annealing at 400C, the film becomes almost transparent. Increasing annealing time at 400C can lead to a small blue shift of the optical gap of the film.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com