Tungsten Oxide History

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 17:19

Tungsten has a rich history dating back to its discovery during the 18th century. Peter Woulfe was the first to recognize a new element in the naturally occurring mineral wolframite. Tungsten was originally known as wolfram, explaining the choice of "W" for its elemental symbol. Swedish chemist Carl Wilhelm Scheele contributed to its discovery as well with his studies on the mineral scheelite.

In 1841, a chemist named Robert Oxland gave the first procedures for preparing tungsten trioxide and sodium tungstate. He was granted patents for his work soon after, and is considered to be the founder of systematic tungsten chemistry.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 17:12

Tungsten oxide, also known as tungsten trioxide or tungstic anhydride, WO3, is a chemical compound containing oxygen and the transition metal tungsten. It is obtained as an intermediate in the recovery of tungsten from its minerals.[1] Tungsten ores are treated with alkalis to produce WO3. Further reaction with carbon or hydrogen gas reduces tungsten trioxide to the pure metal.

2 WO3 + 3 C → 2 W + 3 CO2 (high temperature)

WO3 + 3 H2 → W + 3 H2O (550 - 850 °C)

Tungsten oxide occurs naturally in form of hydrates, which include minerals: tungstite WO3•H2O, meymacite WO3•2H2O and hydrotungstite (of same composition as meymacite, however sometimes written as H2WO4). These minerals are rare to very rare secondary tungsten minerals.

The crystal structure of tungsten trioxide is temperature dependent. It is tetragonal at temperatures above 740 °C, orthorhombic from 330 to 740 °C, monoclinic from 17 to 330 °C, and triclinic from -50 to 17 °C. The most common structure of WO3 is monoclinic with space group P21/n.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Preparing APT by Adding Nitric Acid Solution

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 16:52

Process for preparing APT comprising the steps of: A. leaching of wet ammonium paratungstate by slowly adding wet ammonium paratungstate to stirred pure water while slowly adding a 1:1 to 1:4 nitric acid (HNO3) solution to control the solution at pH 3 to 5 for the occurrence of the following reaction:

5(NH4)2O.12WO3.5H2O+4HNO3═(NH4)6H2W12O40.6H2O+4NH4NO3 when WO3 content of the solution reaches 130 to 160 g/L, the solution is stirred and boiled for 20 minutes or more, and then filtered to obtain a dilute solution of APT; B. converting the dilute solution of APT to a concentrated solution of APT by standing and aging the dilute solution of APT for 2 to 6 hours, filtering the aged dilute solution of APT to obtain a first filtrate, concentrating the first filtrate by heating, in a reactor, with ammonia water having a concentration in the range of 1:4 to 1:6 to adjust the first filtrate to a pH in the range of 3-4, repeating the heating step until the first filtrate reaches a density in the range of 1.8-2.2, and thereafter cooling the first filtrate for 1-4 hours, filtering the first filtrate to obtain a second filtrate, standing and aging the second filtrate, in a settling tank, for 5-12 hours, and filtering, via a suction filter, the second filtrate to obtain a concentrated solution of APT; and C. spray-drying of the concentrated solution of APT into a powdery APT with a high-speed centrifugal spray-dryer or a spray atomizing dryer.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Coated Tungsten Carbide Cutting Tools Use Limitations

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 11:17

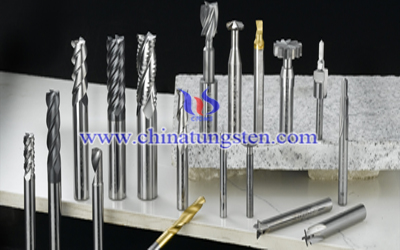

Coated tungsten carbide cutting tools with excellent mechanical properties, can improve the machining efficiency and tool life. Rational use of coated tungsten carbide cutting tools are an effective way to reduce processing costs and improve product quality. Although coated tungsten carbide cutting tools, although many advantages, the use of more and more widely used, but it can not fully replace the ordinary uncoated tungsten carbide cutting tools.

(1) The strength and toughness of coated tungsten carbide cutting tools are lower than uncoated tungsten carbide cutting tools, coated tools and therefore not suitable for roughing and interrupted cutting big impact especially under heavy load, and is not suitable for processing with hard Quality inclusions material.

(2) In order to enhance the strength of the coating edge of the blade, blade coating blunt blade to go through treatment, thus coated blade is not sharp if not coated tungsten carbide cutting tools, it is not suitable for a small amount of feed (eg <0 .015mm ) finishing.

(3) Coated tungsten carbide cutting tool at a low speed, prone to flaking, chipping and other phenomena, it is not appropriate for low-speed cutting.

(4) coated tungsten carbide cutting tools are not suitable for processing heat-resistant alloys, titanium alloys, non-ferrous metals and non-metallic materials.

(5) General coated tungsten carbide cutting tools for deep hole drilling, cutting, threading and poor chip difficult to discharge machining results.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Multi-Coated Tungsten Carbide Cutting Tools Application

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 11:13

Multi-coated tungsten carbide cutting tools coating composition variety of ways to meet the processing conditions vary, the processing should be processed according to the material properties and processing characteristics of the design coating composition, coating thickness. Commonly used multi-coated tungsten carbide cutting tools can be divided into four series: TiC / TiN, TiC / TiCN / TiN, TiC / Al2O3 and TiC / Al2O3 / TiN. The first two categories apply to ordinary semi-fine and fine plus workers, the latter two for high-speed and heavy-duty cutting.

Multi-coated tungsten carbide cutting tools combines the advantages of a single coating. For example, TiC-Al2O3 -TiN three blade coating on a substrate coated TiC coating ensures firm adhesion of the coating and the substrate, and a blade in the middle and a high resistance to mechanical wear properties at low speed cutting conditions; Al2O3 coatings applied thereon, be obtained at high temperatures have good chemical stability and insulation properties, so that the blade substrate temperature is too high and will not be plastically deformed, and therefore have high durability in high-speed cutting; On Al2O3 coating and then coated with TiN, the tool will enable the friction coefficient is small, smooth chip discharge, can reduce the cutting temperature and prevent sticking knife phenomenon, reduce tool crater wear, but also to reduce BUE generation. In actual production should be used reasonably and processing characteristics of the coating according to the nature of the material being processed.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

A Method of Extracting From the High Molybdenum Scheelite Tungsten, Molybdenum

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 08:58

A tungsten, molybdenum is extracted from the high molybdenum scheelite.

Process: the high molybdenum scheelite sulfuric acid - mixing phosphoric acid leaching; leachate was isolated using a cooling crystallization method after phosphotungstic acid crystals dissolve in acid solution, the secondary cooling crystallization, and then dissolved ammonia - ammonium magnesium law except phosphorus - in addition to molybdenum selective precipitation - evaporation and crystallization treatment can have 0 APT line with national standards; a cooling crystallization mother liquor by extraction of molybdenum mention - ammonium stripping - impurity - after the transfer process can be obtained acid molybdate ; the rich more than the acid raffinate and the secondary cooling crystallization mother returned directly leaching, to achieve the cycle acids.

The present invention enables efficient tungsten and molybdenum, atmospheric extraction, tungsten, molybdenum leaching rate of more than 98.5%; freeze crystallization and extraction process can effectively achieve complete separation of tungsten, molybdenum, reducing the processing burden on the follow-up process; leaching process is simple acid consumption less, and to achieve most of the acid leaching cycle, which greatly reduces the cost of production and waste discharge.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

Nickel-tungsten Alloy Plating Mold Analytic Process(a)

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 08:54

Insiders know that the quality of the parts is closely related to the quality of the mold. Many die (such as die casting) of the surface must be plated in order to improve the corrosion resistance, abrasion resistance, oxidation resistance and hardness properties. According to the HC surface network Xiaobian understand, despite the traditional chrome technology mature technology, stable quality, but because chromium is a toxic substance, serious environmental pollution. Therefore, the elimination of pollution, environmental protection, clean production, the path of sustainable development.

Nickel-tungsten alloy plating is to improve the quality of mold, to extend die life, a good choice for clean production. Nickel, tungsten high hardness, wear resistance, and molten matrix adhesion and high temperature. Fine crystalline nickel-tungsten alloy plating bright, good wear resistance, combined with the strong base, high hardness, Vickers hardness at elevated temperatures up to 1000 or more. The technology in recent years by the parties concerned, will gradually replace the mold chrome plating, however, according to HC Xiao Bian understood that the technology prevailing coating roughness, uneven, pitting and other defects, severely restricts their application development. Let Xiaobian for you to resolve mold electroless nickel-tungsten alloy process recipe and process.

Bath formulation and process

Bath mainly composed of sodium tungstate, nickel sulfate and sodium citrate, whose contents were 40 ~ 45gL, 20 ~ 30gL, 40 ~ 50gL.

Process:

Sandblasting → Check → Degreasing Cleaning → Plating → Test

Coating quality defects and causes

Common tungsten nickel plating quality defect is pitting more rough side and white spherical particle coating, coating and central side corners and R at serious inequality, and even the corners, R occurring at the micro cracks.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Nickel-tungsten Alloy Plating Mold Analytic Process(a)

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 08:53

Insiders know that the quality of the parts is closely related to the quality of the mold. Many die (such as die casting) of the surface must be plated in order to improve the corrosion resistance, abrasion resistance, oxidation resistance and hardness properties. According to the HC surface network Xiaobian understand, despite the traditional chrome technology mature technology, stable quality, but because chromium is a toxic substance, serious environmental pollution. Therefore, the elimination of pollution, environmental protection, clean production, the path of sustainable development.

Nickel-tungsten alloy plating is to improve the quality of mold, to extend die life, a good choice for clean production. Nickel, tungsten high hardness, wear resistance, and molten matrix adhesion and high temperature. Fine crystalline nickel-tungsten alloy plating bright, good wear resistance, combined with the strong base, high hardness, Vickers hardness at elevated temperatures up to 1000 or more. The technology in recent years by the parties concerned, will gradually replace the mold chrome plating, however, according to HC Xiao Bian understood that the technology prevailing coating roughness, uneven, pitting and other defects, severely restricts their application development. Let Xiaobian for you to resolve mold electroless nickel-tungsten alloy process recipe and process.

Bath formulation and process

Bath mainly composed of sodium tungstate, nickel sulfate and sodium citrate, whose contents were 40 ~ 45gL, 20 ~ 30gL, 40 ~ 50gL.

Process:

Sandblasting → Check → Degreasing Cleaning → Plating → Test

Coating quality defects and causes

Common tungsten nickel plating quality defect is pitting more rough side and white spherical particle coating, coating and central side corners and R at serious inequality, and even the corners, R occurring at the micro cracks.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Woodcutting Tools Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 04 March 2015 16:03

Cutting wood in industrial production the most basic, the most extensive and important process, a direct impact on productivity, processing costs and energy consumption. The quality of the tools can carry out normal cutting, cutting quality woodworking tools and materials are related to the cutting section. Requirements of woodworking tools in high-speed, and withstand shock loads under cutting conditions can be maintained long sharp cutting tools performance. To this end, woodworking tools must have the necessary material hardness and wear resistance, sufficient strength and toughness, a certain process (eg, welding, heat treatment, machining and grinding, etc.).

tungsten carbide woodcutting tools is extremely hard, refractory metal tungsten carbides (WC, TiC) with Co, Ni, and so do the binder sintered powder metallurgy products. Its properties are dependent on the type of metal tungsten carbide, performance, the number, size and amount of the binder. Tungsten carbide woodcutting tools hardness of HRC74 ~ 81.5, its hardness with increasing binder content decreases. Tungsten carbide woodcutting tools content over high-speed high-temperature tungsten carbide steel, so good thermoplastic, cutting temperature resistant up to 800 ~ 1000 ℃ in. 600 ℃ ambient temperature exceeds high-speed steel hardness, hardness than steel at room temperature at 1000 ℃. Tungsten carbide woodcutting tools mainly made of YG class tungsten carbide which metal cobalt (Co) do binder, tungsten tungsten carbide (WC) for hard phase.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Grades

- Details

- Category: Tungsten Information

- Published on Wednesday, 04 March 2015 16:00

Tungsten carbide cutting tools is an important tools indispensable, whether ordinary machine tools, or advanced CNC machine tools (NC), machining centers (MC) and flexible manufacturing systems (FMC), the tools must rely on to finish machining. Development of tungsten carbide cutting tools have a direct impact on improving productivity and processing quality. Materials, structure and geometry of the cutting tools is to determine the three elements, including the performance of tungsten carbide cutting tools materials plays a key role.tungsten carbide cutting tools materials mainly tungsten carbide, the grade is usually divided into three categories:

1. YG class (WC-Co type): This class tungsten carbide tools manufacturer has good toughness, wear resistance, thermal conductivity, etc., mainly for machining cast iron, non-ferrous metals and non-metallic.

2. YT class (WC-TiC-Co type): Added to TiC material, so that the material of increased hardness and wear resistance, but reduced bending stiffness. Kind of cemented tungsten carbide has high hardness and high heat resistance, adhesion, good oxidation resistance, suitable for machining steel, cutting tools wear small, high durability.

3. YW class (WC-TiC-Ta-Co Class): Add TaC materials in order to improve the strength of the tools, toughness and red hardness. Such tungsten carbide material has a high temperature hardness, high temperature strength and strong antioxidant capacity, particularly suitable for processing a variety of high-alloy steel, heat-resistant alloys and various alloy cast iron.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com