Tungsten Film Coating Method Using Tungsten Oxide Powders(二)

- Details

- Category: Tungsten Information

- Published on Friday, 06 March 2015 17:54

After a Cu substrate is contacted with tungstenoxide powders, thermal reduction treatment is carried out under hydrogen atmosphere. Namely, the present method includes the steps of putting a substrate of Cu, Ni, Fe, Co, Cr, W, or the like in an upper, middle, or lower portion of a tungsten oxide (WO3or WO2.9) layer and carrying out thermal treatment thereon under a hydrogen atmosphere.

Such a coating method is widely applicable to another species of the metal substrate such as Ni, Fe, Co, Cr, W, and the like as well as Cu. Therefore, the tungsten oxide thin film method according to the present method is applicable to any kind of metal substrates.

A tungsten thin film according to the present method can be coated 500 nm˜25 μm thick by carrying out thermal treatment for 10 minutes to six hours at a temperature range between 650˜1050° C.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Film Coating Method Using Tungsten Oxide Powders(一)

- Details

- Category: Tungsten Information

- Published on Friday, 06 March 2015 17:49

Disclosed is a tungsten film coating method using tungstenoxide powders including the steps of contacting the tungstenoxide powders with a metal substrate and carrying out thermal reduction treatment thereon at a temperature of at least 650° C. under a hydrogen atmosphere just to coat the tungsten film on the metal substrate. Accordingly, the present methodenables to provide a simple method of coating a tungsten thin film on a metal substrate using the phenomenon of tungsten migration through vapor phase when thermal reduction treatment is carried out on tungstenoxide powders without using previous chemical or physical vapor depositions requiring expensive precision equipments or causing environmental pollution.

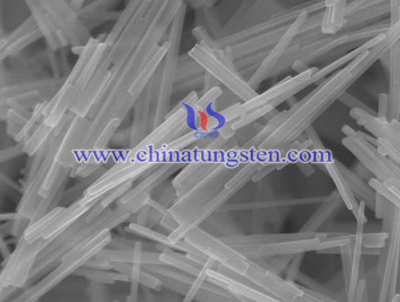

First of all, tungstenoxide (WO3or WO2.9) powders having a grains size of 1˜10 μm are put on a metal substrate such as Cu, Ni, Fe, Co, Cr, W, or the like. When thermal reduction treatment is carried out thereon at 650° C. (temperature from which the metal substrate is coated with tungsten by reduction of the tungstenoxide powders) under a hydrogen atmosphere, the hydrogen gas reacts with oxygen contained in the tungstenoxide powders. Hence, steam is formed as well as composition of tungstenoxide is changed into WO2. Such WO2powders react with adjacent moisture, as shown in the following chemical equation 1, so as to turn into tungstenoxide of WO2(OH)2as a gas phase and hydrogen. The generated gaseous phase tungstenoxide {WO2(OH)2} moves to the neighboring metal substrate by diffusion, and then reacts with adjacent hydrogen again, as shown in the following chemical equation 2, so as to be reduced to solid phase tungsten. In this case, if the metal substrate is around, the reaction by the chemical equation 2 occurs on the metal substrate preferentially (heterogeneous nucleation and growth) so as to coat the metal substrate with a tungsten thin film a few nanometers (nm) to tens of micrometers (μm) thick.

WO2(S)+2H2O(g)WO2(OH)2(g)+H2(g) [Chemical Equation 1]

WO2(OH)2(g)+3H2(g)W(S)+4H2O(g) [Chemical Equation 2

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Gaseous Doping

- Details

- Category: Tungsten Information

- Published on Friday, 06 March 2015 17:44

Tungsten oxide, also known as tungsten trioxide or tungstic anhydride, WO3, is a chemical compound containing oxygen and the transition metal tungsten. It is obtained as an intermediate in the recovery of tungsten from its minerals.Tungsten ores are treated with alkalis to produce WO3. Further reaction with carbon or hydrogen gas reduces tungsten trioxide to the pure metal.

The procsses disclosed is for preparing a film of fluorine-modified tungsten oxide on a substrate. The process comprises providing a tungsten oxide film on the substrate and then exposing the tungsten oxide film at an elevated temperature to a stream of a gaseous fluorocarbon. The exposure takes place for a time sufficient to modify the tungsten oxide with fluorine and form a film having modified infrared adsorption and reflectant properties.

Novel process is disclosed for preparing a fluorine-modified tungsten oxide. The process comprising depositing a tungsten oxide film on a substrate and subsequently exposing the film, at an elevated temperature, to a stream of a gaseous fluorocarbon compound for a time sufficient to decompose the compound and fluorine-modify the tungsten oxide. According to the present process, the resultant fluorine-modified tungsten oxide film has modified infrared absorption and reflection properties. The gaseous fluorocarbon compound can be provided diluted with other gases such as nitrogen or air when it is exposed to the tungsten oxide film on the substrate.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool Wear

- Details

- Category: Tungsten Information

- Published on Friday, 06 March 2015 09:20

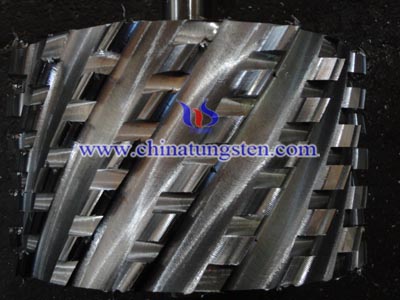

Tungsten carbide cutting tool wide range of applications, both for machining cast iron, non-ferrous metal and non-metallic materials, also suitable for processing a variety of steel and heat-resistant alloys. Both used in the manufacture of tungsten carbide indexable cutter machine folder and welding tools, can also be manufactured in various sizes smaller overall complex tools, such as the overall end mills, reamers, drills, composite processing tool and hobbing knives. At present, with the development of ultra-fine grain tungsten carbide technology, application of tungsten carbide cutting tools is still expanding.

When using cemented tungsten carbide cutting tool machining a variety of workpiece materials, high temperatures can cause cutting tool and the surrounding medium the oxidation reaction, the oxidation wear is easy to form the tool. Metal cutting tools in the process of forming the cutting edge portion has been cut metal adhesion transfer constituted "BUE" BUE was peeling from the cutter blade portion along with tool wear; Tool diffusion also occurs in the cutting process wear is worn between the relative wear caused by surface diffusion of elements; generated during cutting phase at high temperature in different metals, and the emergence of thermal current, which occurred in the electrochemical wear.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool Coating Method - Ion Plating

- Details

- Category: Tungsten Information

- Published on Friday, 06 March 2015 09:18

Ion plating is a tungsten carbide cutting tool under vacuum, or using gas discharge portion ionized vaporized material, the material in the gas ions or ion bombardment of the evaporator while the evaporation substance or a reactant is deposited on the tungsten carbide substrate . It combines fast evaporation deposition plating and sputtering ion bombardment cleaning surface characteristics, especially with a film adhesion, good diffraction properties of a wide range of materials and plating, etc., so this technique to obtain a rapid development of. Coated tungsten carbide cutting tools most basic features of a neutral particle generating ions are ionized by the action of a particular method, and by the negative bias applied on the substrate, so that the generated ions to the substrate and the coating layer have a sustained bombardment, and achieve the coating deposited on the substrate purpose, generally the better the efficiency of ionization.

Tungsten carbide cutting tool ion plating techniques include: Reactivity evaporation ion plating, hollow cathode ion plating, arc ion plating. And several of the arc ion plating technology, with its high rate of metal ions, help to improve film adhesion and film-based performance; deposition rate, high plating efficiency, simple structure, low voltage, safer, become the most successful and most widely used ion plating.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Nickel-tungsten Alloy Plating Mold Analytic Process(b)

- Details

- Category: Tungsten Information

- Published on Friday, 06 March 2015 08:47

1. Pitting

Pitting tiny white coating on the black dot defects, various shapes, some obvious and rules, easy to find, relatively good control; a small amount of eye "invisible", only with the instrument checks.

Analysis:

Trachoma mold matrix, porosity, pitting, etc. caused by poor adhesion; while blasting sand mold adhesion, or poor sandy or sandy been caused by impurities, oil, foreign bodies, dust and other pollution; mold when degreasing adherent emulsion, cleaning and other impurities in the water; dosing caused when using compressed air, water and pipes, tools and environment pollution impurities; bath, activated liquid salt particles were not dissolved acidification of the electrode metal can cause pitting.

Said pitting can be seen intuitively, and some thin layer of adhesive material of the mold surface, the analysis is mainly contaminated sandy before plating the carbon-based compound. It is solid, strong adhesion gradually becomes acid alkali, anti-vibration high viscosity gum. In degreasing, cleaning difficult to remove once negligence inflow plating process, must be covered by the coating, the naked eye is not easy to find, can not make up.

2. Coating roughness

Analysis:

Bath consisting essentially of nickel sulfate, sodium citrate, sodium tungstate, etc., as well as salts, organic complexes and the like. It was found: mold plating defects and impurities in the bath main relevant. Not high purity chemicals, foreign body in the bath, the bath is frequently used to make the bath metal impurities Cu, Fe, Cr, Co content exceeds the allowable range, can lead to coating roughness, increased pitting and white particles.

3. Severely uneven coating thickness

Central and side, the corners, R at the coating serious inequality, and even the corners, R occurring at the micro-cracks.

Analysis:

After the bath using a longer time, the probability of an increase in the coating defects, side and white spherical particles, the corners, especially at the micro-cracks R evident. It was found: When the bath impurities Cu, Fe, Cr, Co content were significantly increased 20,20,20,50mgl, plating quality decreased.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Photocatalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 17:42

The method of producing the tungsten oxide photocatalyst of the present invention includes, for example, a method comprising the steps of:

(a) dispersing tungsten oxide particles in an aqueous solution containing a Pt compound dissolved therein in an amount corresponding to 0.03 to 5 parts by weight of Pt based on 100 parts by weight of tungsten oxide particles;

(b) irradiating with visible light in a wavelength range capable of photoexciting the tungsten oxide particles;

(c) adding a sacrificial agent; and

(d) further irradiating with visible light. According to such a method, Pt particles formed from the Pt compound is supported on the surface of tungsten oxide particles as particles having a particle size defined in the present invention, and thus the objective tungsten oxide photocatalyst can be obtained.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Processing

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 17:35

Tungsten oxide, WO3, is a chemical compound containing oxygen and the transition metal tungsten. It is obtained as an intermediate in the recovery of tungsten from its minerals.Tungsten ores are treated with alkalis to produce WO3. Further reaction with carbon or hydrogen gas reduces tungsten trioxide to the pure metal.

Methods of selectively etching tungsten oxide relative to tungsten, silicon oxide, silicon nitride and/or titanium nitride are described. The methods include a remote plasma etch using plasma effluents formed from a fluorine-containing precursor in combination with ammonia (NH3). Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the tungsten oxide. The plasmas effluents react with exposed surfaces and selectively remove tungsten oxide while very slowly removing other exposed materials. Increasing a flow of ammonia during the process removes a typical skin of tungstenoxide having higher oxidation coordination number first and then selectively etching lower oxidation tungsten oxide. In some embodiments, the tungsten oxide etch selectivity results partly from the presence of an ion suppression element positioned between the remote plasma and the substrate processing region.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Uses

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 17:31

Tungsten oxide, also known as tungsten trioxide or tungstic anhydride, WO3, is a chemical compound containing oxygen and the transition metal tungsten. It is obtained as an intermediate in the recovery of tungsten from its minerals.Tungsten ores are treated with alkalis to produce WO3. Further reaction with carbon or hydrogen gas reduces tungsten trioxide to the pure metal.

Tungsten trioxide is used for many purposes in everyday life. It is frequently used in industry to manufacture tungstates for x-ray screen phosphors, for fireproofing fabrics and in gas sensors. Due to its rich yellow color, WO3 is also used as a pigment in ceramics and paints.

In recent years, tungsten trioxide has been employed in the production of electrochromic windows, or smart windows. These windows are electrically switchable glass that change light transmission properties with an applied voltage.This allows the user to tint their windows, changing the amount of heat or light passing through.

2010- AIST reports a quantum yield of 19% in photocatalytic water splitting with a caesium-enhanced tungsten oxide photocatalyst.

In 2013, highly photocatalytic active titania/tungsten oxide/noble metal (Au and Pt) composites toward oxalic acid were obtained by the means of selective noble metal photodeposition on the desired oxide's surface (either on TiO2 or on WO3). The composite showed a modest hydrogen production performance.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Preparation

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 17:26

Tungsten oxide, also known as tungsten trioxide or tungstic anhydride, WO3, is a chemical compound containing oxygen and the transition metal tungsten. It is obtained as an intermediate in the recovery of tungsten from its minerals.Tungsten ores are treated with alkalis to produce WO3. Further reaction with carbon or hydrogen gas reduces tungsten trioxide to the pure metal.

Tungsten trioxide can be prepared in several different ways. CaWO4, or scheelite, is allowed to react with HCl to produce tungstic acid, which decomposes to WO3 and water at high temperatures.

CaWO4 + 2 HCl → CaCl2 + H2WO4

H2WO4 → H2O + WO3

Another common way to synthesize WO3 is by calcination of ammonium paratungstate (APT) under oxidizing conditions:

(NH4)10[H2W12O42]•4H2O → 12 WO3 + 10 NH3 + 10 H2O

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com