Ultra-Fine Grain Tungsten Carbide Cutting Tools

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 March 2015 10:16

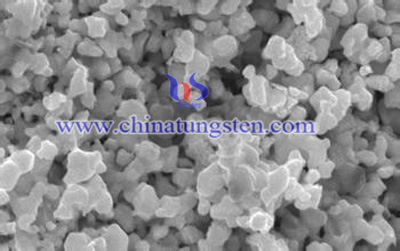

Ultra-fine grain tungsten carbide cutting tools has a high hardness and strength, tungsten carbide by the ultra-fine grain tungsten carbide cutting tools that is 0.5μm of WC, Co, vanadium tungsten carbide and chromium tungsten carbide Cr3C2 VC composition, suitable for In high-speed steel cutting tools wear enough, and as a result of vibrations caused by wear and tear or because the case is too low and should not use the traditional tungsten carbide cutting tools .

Ultra-fine grain tungsten carbide cutting tools WC grain size generally 0.2 ~ 1.0μm, 0.5μm or less at most, a fraction to a few tenths of an ordinary tungsten carbide WC grain size, and its hardness is generally 90 ~ 93HRA, flexural strength of 2000 ~ 3500MPa, the same ratio of cobalt content is generally high WC-Co cemented tungsten carbide cutting tools, and the work material attract each other - the smaller diffusion, especially for heat-resistant alloy, high strength alloy steel and other difficult materials. Fine grain tungsten carbide cutting tools previously used for K classes, but in the P class, ultra-fine tungsten carbide tungsten carbide M class, will be in the WC grains finer subgrain structure defects less comprehensive higher performance direction.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

TDM-8 Tungsten Carbide Hardfacing Electrodes

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 March 2015 08:48

TDM-8 tungsten carbide hardfacing electrodes

Description: TDM-8 tungsten carbide hardfacing electrodes Building Materials Industry recommended products I plant the TDM-8 tungsten carbide hardfacing electrodes, mainly for the delivery of brick spiral mixer blades, brick machine mixing blade, auger, to stick, bulldozers push the bucket, digging bucket, grab and wear characteristics, such as the development.

Tungsten carbide and low hydrogen sodium type coating as the main raw material, with the process technology developed by Kobe, Japan, AC and DC welding layer has high hardness, good toughness, high temperature and wear-resistant characteristics, the use of carbon surfacing prime steel, alloy steel, cast iron, cast steel and other surfaces.

Surfacing Metal: high manganese steel welding core, the amount of 57% tungsten, and gold powder 12%, Mexico cobalt chromium and other elements.

Chemical Composition (%):

C Cr W Mo B

0.05 9.8 5717 4.2

Reference current: φ3.2 90-120A φ4.0 160-190A φ5.0 190-220A

:( Surfacing layer hardness after welding, air-cooled) HRC≥75

Note: 1, before welding debris shall clean the surface of the base metal. 2, should use a smaller current to prevent anti-crack three arcs, such as welding thicker layer can be repeatedly surfacing

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Synthesis of Tungsten Oxide Thin Film by Liquid Phase Deposition

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 17:35

High purity and well crystallized tungsten acid hydrates (H2WO4·H2O) thin films were prepared from H2WO4–HF(aq.) and H3BO3 as precursors by the liquid phase deposition method. The crystal structure was indexed as monoclinic with unit cell lattice constants a=7.517Å, b=6.907Å, c=3.694Å and β=89.58°. The monoclinic phase was transformed into orthorhombic WO3·H2O after heating at 100°C. Further heating from 300 to 500°C resulted in an anhydrous monoclinic WO3 films. The effects of the composition and the reaction time on the deposition and the microstructures of the deposited films were studied by the means of scanning electron microscope (SEM), transmission electron microscope (TEM), X-ray diffraction (XRD) and X-ray photoelectron spectroscopy (XPS). The film formation showed strong dependence upon the composition, whereas the amount of deposition, the shape and the films thickness could be controlled by the reaction time. Cross-sectional TEM image of WO3 film deposited on Au wire indicated that the epitaxial growth of the film was maintained after calcination at 500°C. XPS analysis also revealed the existence of W6+ ions in both the deposited and calcined films.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Gasochromic Tungsten Oxide-based Film Structures

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 17:21

Tungsten oxide thin films were produced by reactive sputter deposition which is an advantageous method because of the opportunity to influence the properties of the films by several parameters. This work focuses on the influence of the oxygen content during the sputtering process and on mixed tungsten and molybdenum oxide films. The oxygen content has a great influence on the film growth velocity and leads to significant differences in crystal symmetry as a function of oxygen partial pressure. Additionally an influence of oxygen content on the gasochromic behaviour was observed. The mixed tungsten molybdenum oxide thin films show no change in the velocity of the gasochromic colouration but the fact that the coloured films show high absorption all over the visible region of the optical spectrum is a significant advantage.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Optimizing Tungsten Oxide Films

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 17:09

Tungsten oxide films are of critical importance forelectrochromic device technology ,such as for smart windows capable of varying the throughput of visible light and solar energy.

Polycrystalline WO3 films grown on macroporous silicon via electrochemical deposition, have been studied as a function of annealing temperature. The hybrid structure was characterized using scanning electron microscopy, energy-dispersive X-ray spectroscopy, X-ray diffraction and Fourier transform infrared spectroscopy. The microstructure and grain-size of the metal oxide film were found to have significant influence on its electrical and sensing properties. DC conductivity measurements reveal the rectifying behavior of the junction, which is found to increase with annealing temperature. The increased sensitivity of the samples annealed at 700 °C has been attributed to a lower grain size, which contributes to an increase in the depletion region per unit length. An extrapolation of the variation of the resistance ΔR/R0=1.5% predicts possible ethanol sensing up to 1ppm.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Thin Films Obtained by Anodisation

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 16:57

Tungsten oxide, WO3, has been reported to possess ferroelectric properties. Ferroelectric materials have potential for use in nonvolatile memory devices, that is, devices in which data is retained even when power is cut off. In addition, tungsten oxide may potentially be used for infrared temperature sensors.

Tungsten oxide nanostructured films were grown on tungsten substrates by anodisation under a fixed voltage and with sodium fluoride as electrolyte. The effect of the anion chloride and the influence of the modifying agent disodium hydrogen phosphate in the tungsten oxide films were also investigated. The structural characterisation of the films was performed by scanning electron microscopy, atomic force microscopy and Raman spectroscopy. The band gap was determined through diffuse reflectance spectroscopy. The thin films were photoluminescent and emitted in the range of 300 to 630 nm when irradiated at 266 nm. The synthesised films efficiently degraded of methyl orange dye in the presence of hydrogen peroxide and 250 nm radiation. The modifying agent was responsible for the improvement of the photocatalytic activity. Films with similar photocatalytic performance were obtained when the system sodium fluoride and disodium hydrogen phosphate were replaced by sodium chloride. The porous structure and low band gap values were responsible for the photocatalytic behaviour.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Fe-doped Tungsten Oxide Thin Films

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 16:54

Tungsten oxide (WO3) is an electrochromic material which has been widely used as the basis for electrochromic-based devices such as displays and light modulating windows. Numerous methods are known for depositing tungsten oxide coatings onto a substrate. Vacuum deposition methods such as sputtering and evaporation are the most commonly used processes, although solution deposition methods are known as well. These solution-based methods generally involve one of three general types of tungsten oxide precursors: colloidal sols, alkoxide derivatives, and peroxy tungstic acid.

The gas sensing characteristics of Fe-doped (10%) tungsten oxide thin films of various thicknesses (100–500nm) prepared by electron beam evaporation. The performance of these films in sensing four gases (H2, NH3, NO2 and N2O) in the concentration range 2–10,000ppm at operating temperatures of 150–280°C has been investigated. The results are compared with the sensing performance of a pure WO3 film of thickness 300nm produced by the same method. Doping of the tungsten oxide film with 10at.% Fe significantly increases the base conductance of the pure film but decreases the gas sensing response. The maximum response measured in this experiment, represented by the relative change in resistance when exposed to a gas, was ΔR/R=375. This was the response amplitude measured in the presence of 5ppm NO2 at an operating temperature of 250°C using a 400 nm thick WO3:Fe film. This value is slightly lower than the corresponding result obtained using the pure WO3 film (ΔR/R=450). However it was noted that the WO3:Fe sensor is highly selective to NO2, exhibiting a much higher response to NO2 compared to the other gases. The high performance of the sensors to NO2 was attributed to the small grain size and high porosity of the films, which was obtained through e-beam evaporation and post-deposition heat treatment of the films at 300°C for 1h in air.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Analysis of Tungsten Oxide Nanowires Film

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 16:25

In the past few years, an increasing interest has been put on the tungsten oxide films due to their potential applications in smart windows, gas sensors, photocatalytic reactions, and optoelectronic devices etc. The unique properties of the tungsten oxide films were usually determined by the oxygen defects and the valence states of tungsten ions. Besides, it is very important to improve the properties of tungsten oxide films and other oxide films by controlling their morphologies and crystalline phases,which mainly depend on the preparation technologies and thermal treating temperatures and atmospheres.

When the temperature of the source and substrate changes, the growth of the tungsten oxide nanowires changes with regularity. i.e., as the temperature of the source of evaporation and substrate increases, the diameter of tungsten oxide nanowires increases gradually and its diameter increases faster than its height; as the temperature of the substrate increase, the height of the tungsten oxide also increases gradually and its height increases faster than its diameter.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Film

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 16:21

Several methods are used to form tungsten oxide films. The methods include sputtering, chemical vapor deposition, and plasma enhanced chemical vapor deposition, in which sub-atmospheric pressure must be maintained. In these methods, large, complex and expensive equipment is needed, and the methods involve significant energy consumption and relatively high operating costs. The films produced by current methods are tungsten oxide films of WO3, without suboxides, and which are colorless or faint yellow, single color films.

It has been suggested that tungsten containing films be formed by a metallo-organic deposition (MOD) method, wherein an organic metal compound is applied to a substrate which is heated to form the desired metal oxide film. Most MOD processes for deposition of transition metal oxides use carboxylate salts. However, tungsten carboxylates have not been easily synthesized.

It is an object of this invention to provide an MOD method for producing a tungsten oxide film by pyrolyzing at least a portion of an alkyl amine tungstate compound; in which the alkyl amine tungstate compound is a soluble alkyl ammonium salt of tungstic acid; in which time and temperature of heating are varied so as to provide a desired color gradient in the tungsten oxide film and suboxides of the tungsten oxide (WO3); and which utilizes a precursor which produces a high tungsten oxide yield thereby forming a relatively dense tungsten oxide film.

It is a further object to provide tungsten oxide films which include suboxides of tungsten oxide (WO3); which have an average ratio of oxygen atoms to tungsten atoms equal to or less than 3:1; which are denser than films produced from currently known MOD precursor compounds; which have a color gradient, that is, a single continuous film marked by regions of different colors; and wherein the regions of color are electrochromic.

In this method, tungsten oxide films are formed without vacuum equipment. Uniform faint yellow to white (colorless) films having essentially no organic matter or impurities are produced, or films having regions of color across the substrate are produced ranging from nearly colorless or faint yellow to deep brown, which offer the potential for inexpensively and controllably darkening windows.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Coated Tungsten Carbide Cutting Tools Mechanical Stress And Impact Damage

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 10:12

When cutting, the role of mechanical stress in the coating surface coated tungsten carbide cutting tools, coating and the substrate is first formed joints easily crack two sources to rapidly penetrate the surface coating matrix expansion, along with cutting progresses, shallow flaking will occur, this time the blade did not fail, as the cutting continues, the base material of the crack gradually extended in parallel in a network of cracks, peeling may occur deep, this time will result in a hard coating alloy tool failure. Residual stress state coated tungsten carbide cutting tools in initiation and propagation of cracks in the surface of the blade about the residual compressive stress can prevent crack propagation, which is resistant PVD coated tungsten carbide cutting tools coating flaking better performance reasons.

Impact damage is the main reason for the occurrence of coated tungsten carbide cutting tools when turning, when the impact load exceeds the allowable strength edge chipping occurs. Although low-temperature hardness of austenitic stainless steel, but it has serious work hardening, so the impact of a significant chipping occurs under load. Cutting edge radius smaller PVD coated tungsten carbide cutting tools, resulting in low impact resistance of the tool, could easily lead to impact damage PVD coated tungsten carbide cutting tools.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com