Ultrafine Tungsten Oxide Affect Ultrafine Tungsten Powder Uniformity

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 March 2015 17:04

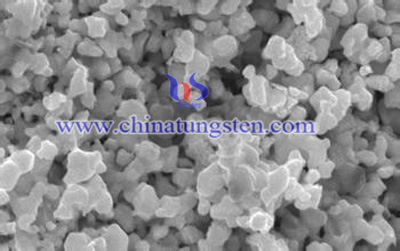

Hydrogen reduction of tungsten oxide, followed by a tungsten carbide is tungsten carbide cemented carbide industry in the preparation of the most common methods, called "conventional hydrogen reduction process." The restore process is crucial, because tungsten carbide powder final size depends largely on reducing the resultant tungsten powder particle size, therefore, tungsten powder fineness and uniformity of tungsten carbide powder manufacturing process becomes a key factor. As reducing conditions in the preparation of ultrafine tungsten powder process, should be kept cold, humidity, push the boat along the hydrogen, is not conducive to WO2 (OH) 2 formation. For tungsten oxide material, although blue tungsten oxide (TBO) is currently taking the most widely used tungsten powder raw material by hydrogen reduction system, but it is a chemistry and physics from Xanadu is difficult to precisely define industrial products. Clearly, the performance of the tungsten oxide starting material affects the performance and behavior of the final reduction of tungsten powder, a low temperature (700 ℃ ~ 800 ℃) performance of the tungsten oxide strongly affects the reduction kinetics process, blue tungsten oxide than the yellow oxide at low temperatures Tungsten has a higher activity.

Tungsten oxide materials can be prepared to take appropriate reducing conditions in the ultrafine tungsten powder; single-phase tungsten oxide obtained after reduction by ultrafine tungsten powder fine and uniform, multiphase tungsten oxide produced by the reduction of fine tungsten powder uneven; In the low temperature, low humidity, high hydrogen flow rate of stable hydrogen reduction under the process conditions, for the tungsten oxide has a phase component, which can be approximately predicted uniformity ultrafine tungsten powder. Thus, in the manufacture of cemented carbide crystallites, characteristics should be considered in-phase component of the tungsten oxide material.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Hexagonal Tungsten Oxide Synthesis

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 March 2015 17:04

Transition metal oxides are tungsten oxide, which is a n-type semiconductor, there is a wide band gap (2.5 ~ 3.5eV). It has a photochromic, electrochromic, photochromic gas and other characteristics, in terms of information on functional materials, catalysis, magnetic materials, information memory device, a display piece and others have a wide range of applications.

Low temperature hydrothermal synthesis method is commonly used method for producing tungsten oxide nanomaterials under hydrothermal conditions for obtaining tungsten oxide nanoparticles with different morphologies, aid played a key role, can effectively control the growth direction of the crystal. Fibrous tungsten oxide having a large specific surface due to the advantages in catalysis concern. Size and distribution of high quality nanofibers one must have the basic features, in order to achieve the above purpose, in the preparation of the crystal during the growth process and hope to form nuclei nuclei is well controlled to avoid the growth process nuclei high local concentrations simultaneously homogeneous nucleation and heterogeneous nucleation, resulting in non-uniform dispersion particle size. Now often used as an adjuvant to obtain a sulfate nanofibrous tungsten oxide, common with ammonium sulfate, potassium sulfate, etc., and no use of sulfuric acid has been reported as an adjuvant guanidine, guanidine sulfate as an adjuvant preparation of nano tungsten oxide process , the auxiliary agent is not directly reacted with the sodium tungstate, but hydrolysis by sulfuric acid guanidine structure crystal ion SO2-4, NH + 4 is reacted with sodium tungstate. Guanidine sulfate under hydrothermal conditions is a process of slow hydrolysis reaction, to control the entire nanofiber growth process, and thus will not cause a sudden increase in the reactant solution, the crystal structure of the ion can be uniformly distributed in the various parts of the solution, and the reaction sodium tungstate was mixed at the molecular level can be achieved, thus ensuring a uniform solution throughout the fibrous generated tungsten oxide.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

4 Reasons to Use Tungsten Ice Fishing Jigs(d)

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 March 2015 08:50

Great for downsizing

“Tungsten allows anglers to have a smaller profile,” Brosdahl said. “When crappie are fussy, a small bait that fishes heavy is very important.”

Tungsten’s a natural choice for downsizing given it packs the same weight into a smaller footprint than a similarly weighted lead jig. Downsizing is a common tactic for finessing wary crappie on lakes receiving heavy angling pressure. Going small also teases hits from inactive crappie, which is typically the case during cold fronts and much of mid-winter.

Small baits also mimic a crappie’s tiny winter forage. Brosdahl relies on many presentations for coaxing slabs to bite. Here are three favorites for ice fishing:

Northland Mooska Tungsten Jig tipped with a maggot or threaded with half a wax worm for finessing zooplankton-eaters.

Northland Tungsten Fire-Ball Jig rigged with a 1 1/2-inch Impulse Bro Bloodworm to replicate chironomid larvae and other wormy snacks.

Northland Tungsten Banana Bug combined with a plastic minnow. The front weighted jig combined with the soft-bait’s tail results in a slight forward swimming action on the fall. Nodding the jig on bottom copies minnow fry picking food off the floor.

Tungsten comes at more expense than lead. But, for many hard-core ice anglers, it’s a small price to pay given tungsten’s advantages. Bear in mind, using tungsten isn’t an all or nothing situation. Adding just a few of these heavy-metal ice jigs to your collection will give you more options for fooling wary slabs.

Tip: In addition to jigs, tungsten spoons are also available for another compact, fast-sinking presentation choice.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Blue Tungsten Reduction Mechanism

- Details

- Category: Tungsten Information

- Published on Monday, 30 March 2015 17:07

The main components of the blue phase is B- tungsten oxide, tungsten, tungsten blue particle surface is rough, but with more of a crack, it is because there is a crack in the B- tungsten oxide reduction process in favor of hydrogen into the interior of the particle reduction reaction and the generated steam is discharged. With blue tungsten in hydrogen reduction, the main-phase component of the tungsten oxide oxygen atom declining, gap increasing gradually transformed into the tungsten oxide of the tungsten oxide Y-First, the surface of the tungsten oxide in the tungsten oxide is formed, which is acicular particle shape and short rod arranged quite irregular, and the resulting acicular short rod B- Y- tungsten oxide and tungsten oxide crystal comparison, particles finer.

With the reduction of the depth tungsten oxide oxygen atom further reduced, while further increasing the vacancy. From tungsten oxide develop into tiny needle or short rod, and become more loose, it is easy to generate hydrogen gas into the interior of the particles and the discharge of water, because the Y- tungsten oxide when converted to tungsten dioxide, by needle or short Y- a single rod-like tungsten oxide needle bar into a single crystal tungsten dioxide formed by the development, tungsten dioxide particles consisting of a plurality of tungsten dioxide crystal beginning to coalesce into a sintered body, while it becomes more dense particles, shape with tungsten powder particle morphology was very similar to the last $ # This process is therefore reduction of tungsten blue ultrafine tungsten powder Preparation key link. If control the reducing conditions of the process, with the tungsten oxide can be prepared Y- ultrafine tungsten powder.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Using Purple Tungsten Oxide as Raw Material

- Details

- Category: Tungsten Information

- Published on Monday, 30 March 2015 17:01

Purple tungsten oxide (Violet Tungsten Oxide, VTO), referred to as purple tungsten. Purple tungsten oxide refers to paratungstate (Ammonium Paratungstate, APT) as raw materials under certain conditions Calcination, decomposition, reduction generated purple tungsten oxide. General purple or blue-purple crystalline powder. By strong fissile octahedral structure, intrinsic crystalline needle and rod. Purple Tungsten is a tungsten oxide, the chemical formula for WO2.72 or W18O49. Purple and yellow tungsten oxide, tungsten (the yellow tungsten WO3), blue tungsten oxide (referred to as blue tungsten W20O58 or WO2.90) and brown tungsten oxide (WO2) collectively known as tungsten oxide. The tungsten oxide can be used as raw material for the production of tungsten powder, tungsten because of its unique nature purple to purple tungsten tungsten powder products as raw materials, has generated fast, fine-grained and so on.

Ultrafine cemented carbide demonstrates a superior combination of higher wear resistance and higher hardness. The key factor to obtain ultra- fine carbides with pure, fine and homogeneous grain is using finer starting tungsten carbide powder with tight particle size distribution. Two kinds of ultra- fine carbides were synthesized by adopting blue and purple tungsten oxides as rawmaterials respectively. And, after contrasting the properties of the two kinds of alloy,it was concluded that the alloy using purple tungsten oxide as raw material has better over- all properties with smaller grain size, higher strength and hardness.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Factors Tungsten Oxide Mesoporous Structure (B)

- Details

- Category: Tungsten Information

- Published on Monday, 30 March 2015 16:44

Ethanol and distilled water as a dispersing agent, silicon and silicon acid mesoporous materials than 3:1, the calcined at 600℃ and after HF treatment of tungsten oxide N2 adsorption - desorption, N2 adsorption - desorption isotherms at relatively pressure (p / p0) is between 0.1 to 0.2 of a sudden the weak, the relative pressure of about 0.6-0.8 adsorption curve there is a clear conflict more, and there is between the branch and the adsorption and desorption branches noticeable lag ring, which is produced by the N2 in the pores of capillary condensation phenomenon, which also indicates that the material prepared mesoporous channels.

Preparation of mesoporous material having pore diameter of two-channel. Reasons for the formation may be due to the dual aperture silicotungstic acid SiO2 pore filling during the filling of dissatisfaction, or in the process of formation of the tungsten oxide polymerization between molecules caused some vacancies in the bore, so when removing the SiO2 pores becomes large so that, while forming a double-aperture is ethanol and distilled water as the dispersant, silicotungstic acid material than the silicon mesopores 3/1 when calcined at 600 ℃ tungsten oxide mesoporous material prepared The structural parameters, the specific surface area can be seen that the dispersant is prepared using ethanol as tungsten oxide mesoporous material with a pore volume of distilled water are higher than the dispersant.

Ethanol at room temperature The contact angle of the mesoporous silica surface was 11°, the water contact angle of the surface of the mesoporous silica is 26 °, than ethanol distilled water described mesoporous silica having better wetting properties, more conducive to the silicon acid into the pores of the silica and the formation of mesoporous materials.

Mesoporous silica as a hard template, and silicon acid compound, and then the HF treatment to remove silica prepared by having a large specific surface area and pore size of mesoporous tungsten oxide dual optimum conditions are: Silicotungstic acid and mesoporous silica composite material ratio (m (WO3) / m (SiO2)) in between 3 to 4:1, and calcined at 600-750 ℃. When using ethanol as a dispersant compound , the resulting mesoporous WO3 specific surface area and pore volume than when distilled water as the dispersant large, mainly due to ethanol ratio of distilled water to the mesoporous silica having better wetting properties.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

.Factors Tungsten Oxide Mesoporous Structure (A)

- Details

- Category: Tungsten Information

- Published on Monday, 30 March 2015 16:40

Composites calcined in the silica pores of silica acid is converted to form the influential tungsten oxide, tungsten oxide calcination temperature of crystallization and its mesoporous structure. This paper explores at 550-950 ℃ between different calcination temperature impact of mesoporous tungsten oxide structure. Ethanol as a dispersant, and silicotungstic acid silica mesoporous material than m (WO3) / m (SiO2) 3/1, after calcination at different temperatures HF treated tungsten oxide. When the calcination temperature at 550 ℃, almost no diffraction peaks in the small, indicating the degree of structural ordering poor, while N2 adsorption - desorption characterization of the specific surface area of 42.7m2 • g-1, and after more than 600 ℃ calcined surface area of 68.0m2 • g-1 there were significant decreases when the calcination temperature is 600-750 ℃ when, in the vicinity of 2θ = 1 ° there is a clear diffraction peaks, indicating that the tungsten oxide upon calcination crystalline SiO2 is preferably within the hard model , ordered mesoporous structure after HF treatment of tungsten oxide is preferably, but in a small angle diffraction, no diffraction peaks were observed secondary peaks, indicating that the mesoporous structure is not a good long-range order in the calcination temperature reached 850 and 950 ℃, the structure of the degree of order is poor, there may be caused by high temperature volatile part of the tungsten oxide, thus affecting its structure degree of order.

Small angle XRD patterns of ethanol as a dispersing agent in a different material than silicon tungsten acid mesoporous silicon when, 600 ℃ calcination and get treated by HF tungsten oxide mesoporous materials can be seen when the silicon and silicon-mediated acid hole material ratio m (WO3) / m (SiO2) is 2:1, the figure in the small-angle XRD diffraction peaks, showing that structural order is poor, while the N2 adsorption - desorption characterization of the specific surface area of 40.7m2 • g-1, and calcined at 600 ℃ than the surface area of 68.0m2 • g-1 significantly decreased compared to when the material ratio 3/1 and 4:1, there is a distinct diffraction peaks near the (211), Description In this mass ratio is preferably within a range of structures can be prepared tungsten oxide mesoporous material. When silicotungstic acid and mesoporous silicon material ratio 5:1 when, in the small-angle XRD pattern of the diffraction peaks is not obvious, indicating that its structure Sequence poor, probably due to the content of tungsten is too high, the silicon oxide outside the tunnel crystallization.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Electrochromic Films

- Details

- Category: Tungsten Information

- Published on Monday, 30 March 2015 16:39

Electrochromic film materials include various organic and inorganic compounds, of which the most studied is tungsten oxide, the main methods of preparation include vacuum thermal evaporation, electron beam evaporation, sputtering, vapor deposition, electrodeposition and sol - gel method. Electrochromic film a certain temperature heat treatment can improve their adhesion and cycle life, but the high temperature heat treatment tends to affect the magnitude of the response time and color film. General physical preparation methods require high temperature heat treatment, such as electron beam evaporation method needs a heat treatment 500e, 350e thermal evaporation requiredRF sputtering need 200 ~ 300e. These methods are often due to expensive equipment, technical complexity and demanding process conditions and subject to certain restrictions; the chemical preparation of the sol - gel method is a simple equipment, low temperature deposition uniformity and easy preparation method for preparing a large area, but usually 100e need more heat. Alkoxide method as required 250e of heat treatment, ion exchange need 150e, halogenated oxidation need 120e. Bessiàre etc.

80e heat treatment method has been reported, and in a soft deformable polyethylene terephthalate (PET) Preparation of the electrochromic thin film on the substrate so as to cover any irregularities in the surface shape of the object, but the film thus prepared The cycle life of only dozens of times, can not meet the actual needs. Sodium tungstate as raw material, ion exchange acid solution, ethanol, and polyvinyl alcohol (PVA) as an additive, by sol - gel prepared by the superior performance of the tungsten oxide electrochromic films. This film just 75e of the heat treatment temperature, the driving voltage of -1 ~ + 1V, fully colored and fade time of only a few seconds, coloring in aqueous solution - fading cycles up to 600 times, the color can be kept after coloring number of days.

The resulting film is colorless and transparent, colored blue after uniform color. At 300 ~ 900nm wavelength, variation in the film of the colored state and the faded state transmittance. When fading state, the transmittance in the visible and near-infrared region are more than 93%, but in the near-ultraviolet region due to the absorption of the matrix glass, so that a decrease in transmittance. When the colored state, in the region of 600nm or more has a good absorption, transmittance of 21% or less, which is displayed with its appearance coincides blue. Transmittance in the colored state of 600nm or less significantly increased, but the colored state and the faded state at 500nm transmittance difference also more than 50%. Test results show that the film color changed significantly, having good light controllability.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Mesoporous Materials

- Details

- Category: Tungsten Information

- Published on Monday, 30 March 2015 16:36

1992 Kresge first reported mesoporous silica materials with regular pore structure of MCM-41 called for the study of the molecular sieve material has opened up a new field. Because of mesoporous materials with large specific surface area , uniform adjustable aperture (2-50nm), rules controllable appearance, high thermal stability and hydrolysis resistance and other properties, so that in the separation, adsorption, catalysis, biological materials, information materials, carbon nanotubes prepared applications in areas such as more and more people's attention.

Preparation and properties of mesoporous silica mesoporous silica material has been widely studied, with different structural features have been very easy to prepare, but its performance is difficult to meet the application requirements of different areas, so a non-silicon-type mesoporous research materials more and more. Because the characteristics of tungsten oxide itself in the field of catalysis applications, electrochromic electrode materials, energy storage and microwave materials, so that the mesoporous tungsten oxide material is expected to play a more effective role in these areas. About Preparation of tungsten oxide mesoporous materials at home and abroad have been a number of related stories. The preparation method can be divided into two categories, one is a long-chain organic compounds as a template, tungsten hexachloride tungsten source, after the ethanol gelation by calcination or solvent extraction to remove the organic template agent to prepare tungsten oxide mesoporous materials, but mesoporous tungsten oxide high-temperature calcination easily collapse, and the use of extraction to remove the organic template, and it is difficult to be repeated extraction divisible, while tungsten oxide difficult fully crystallized, so these methods ultimately difficult to get a better structure of tungsten oxide mesoporous materials; the other is hard template method, which uses mesoporous silica as a template to make mesoporous tungsten oxide after its crystallization temperature HF to remove the template, the template is removed such methods in milder conditions, and the template is removed completely. Most of phosphotungstic acid as tungsten source, thus the introduction of impurities of phosphorus, and the emphasis on the application performance of mesoporous tungsten oxide research, unexplored The preparation conditions for the tungsten silicon acid source mesoporous silica (KIT-6) as a template, the template was prepared to explore with a hard tungsten oxide mesoporous materials and preparation conditions.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Porous Silicon and Tungsten Oxide Thin Films Application

- Details

- Category: Tungsten Information

- Published on Monday, 30 March 2015 16:31

From the beginning of the industrial revolution, human society has made tremendous progress, while paying the environmental pollution and ecological deterioration of the enormous cost, from photochemical smog to acid rain, air pollution is getting worse, NO2 in which plays a very important addition to the impact .NO2 volcanic eruptions and other natural sources of foreign, mainly from the burning city car exhaust fuel. In addition, industrial production process can produce some NO2. It is estimated that, worldwide anthropogenic pollution emission of nitrogen oxides per year is approximately 53Mt. The main harm the atmosphere, water and soil, etc., can cause direct harm to the human respiratory system and eyes. Our indoor air quality standards in the ceiling on the NO2 concentration of about 0.12ppm.

As people gradually improve the quality of life requirements, detection of NO2 gas in recent years has become an important topic, and then study the gas sensor has achieved rapid development, wherein the metal oxide semiconductor material meteoric rise, SnO2, ZnO, WO3, etc. are been extensively studied, but previous studies showed that the outstanding problems of these materials is that the higher operating temperature, selectivity and sensitivity, such as less than ideal, is not conducive to the development trend of integration and low power consumption, so people using the included material doped composite, low-dimensional technology, using different preparation methods, research and even low ambient temperature sensitive materials and other ways to reduce the operating temperature of the sensor.

Porous silicon because of its unique optical properties at room temperature and gas sensing properties of the application in the biomedical field, since the 1990s, are more and more attention. Porous silicon surface area because of its great and has a high surface activity, the external environment can absorb large amounts of gas molecules change their electrical properties or optical properties exhibited gas sensing performance. Application of porous silicon as a gas sensing material, generally use optical excitation, doped with another material or composite approach to achieve the purpose of improving the sensitivity or selectivity. Tungsten oxide as a common n-type metal oxide semiconductor material, also has good electrochromic properties and excellent gas sensing characteristics. In the n-type ordered porous silicon surface layer of tungsten oxide thin films by magnetron sputtering using porous silicon at room temperature and gas sensing performance of tungsten oxide NO2 better sensitivity advantages of gas sensing properties of composite structures. Aperture ordered porous silicon is between mesoporous silicon and macroporous silicon. Sufficiently large pore size and high porosity conducive to the formation of a good film with tungsten oxide composite interface, but also ensures high sensitivity to gases.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com