Direct Hydrothermal Precipitation of Pyrochlore-Type Tungsten Trioxide Hemihydrate

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 16:24

Pyrochlore-type tungsten trioxide hemihydrate (WO3·0.5H2O) powder with the average particle size of 0.5μm was prepared successfully from the weak alkaline sodium tungstate solution by using organic substances of sucrose or cisbutenedioic acid as the acidification agent. The influences of solution pH and acidification agents on the precipitation process were investigated. The results showed that organic acidification agents such as sucrose and cisbutenedioic acid could improve the precipitation of pyrochlore WO3·0.5H2O greatly from sodium tungstate solution compared with the traditional acidification agent of hydrochloric acid. In addition, the pH value of the hydrothermal system played a critical role in the precipitation process of WO3·0.5H2O, and WO3·0.5H2O precipitation mainly occured in the pH range of 7.0 to 8.5. The precipitation rate of tungsten species in the sodium tungstate solution could reach up to 98 pct under the optimized hydrothermal conditions. This article proposed also the hydrothermal precipitation mechanism of WO3·0.5H2O from the weak alkaline sodium tungstate solution. The novel method reported in this study has a great potential to improve the efficiency of advanced tungsten trioxide-based functional material preparation, as well as for the pollution-reducing and energy-saving tungsten extractive metallurgy.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Pyrochlore-type tungsten oxide structure

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 15:46

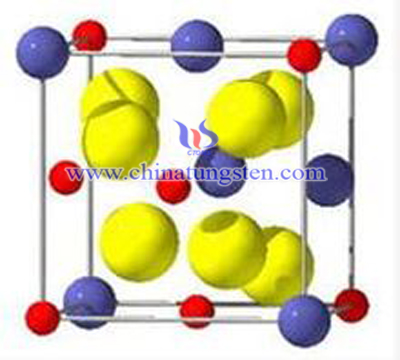

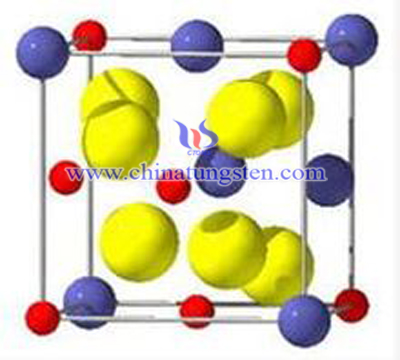

Pyrochlore type tungsten oxide (often referred to as H2W2O7 or WO3 • 0.5H2O) A vacancy is a layered perovskite-based oxide, due to the molecular sieve having a mesh structure and dielectric stability, and in catalysis, sensing, electrical photochromic, fuel cells and other areas showed a wide range of applications. Further, the tungsten oxide powder pyrochlore type after concentrated hydrochloric acid Na element can be efficiently removed, and after firing can be directly obtained WO3, tungsten industry is expected to be novel intermediates.

Pyrochlore type WO6 tungsten oxide is distorted octahedral structural motifs, by the angle of the top of the tungsten oxide rigid skeleton to build a layered structure with a six-membered ring channels, it has a three-dimensional channel, this channel is conducive to the rapid migration of cations and exchange. Wherein a water molecule is formed directly in contact with the two-dimensional layer structure of tungsten by hydrogen bonding interactions between the layers. Standard stoichiometric H2W2O7 cubic crystal lattice parameters a = 10.305 (3), Z = 16. On the thermal stability is concerned, at temperatures above 320 ℃, tungsten oxide pyrochlore-type structure is destroyed, i.e. WO6 octahedron structural motifs, by angular tungsten oxide build from the top of a rigid skeleton having a six-membered ring pore network structure collapsed, forming a quadrature type of tungsten oxide.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Pyrochlore Type Oxide Reaction Mechanism

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 15:45

Pyrochlore type oxide, tungsten oxide (often referred to as H2W2O7 or WO • -0.5H2O) to WO6 distorted octahedral structural motifs, by a rigid skeleton top corner WO6 construct a layered structure with the bore having a six-membered ring, in layers formed between road. Which has an n-type semiconductor properties and microwave absorption properties, as a new industrial materials, it photochromic, electrochromic, gas discoloration caused by aspects, catalysis have a very important significance. In addition, the tungsten oxide pyrochlore type after the firing energy directly into tungsten trioxide, tungsten trioxide can be prepared as intermediates.

Currently preparation of tungsten oxide pyrochlore type used mainly soft chemical synthesis method and hydrothermal synthesis. Hydrothermal synthesis method is widely applied in the field of inorganic materials synthesis, the advantage of easy-to-control hydrothermal conditions, the resulting product of high purity, good dispersion, size and easy to control. Currently Hydrothermal Synthesis of tungsten oxide pyrochlore type usually sodium tungstate solution for raw materials, hydrothermal reaction after acidification some time to prepare. According to the findings of the different researchers, sodium tungstate solution pH in the range of 2.0 to 8.9 can hydrothermal synthesis of tungsten oxide pyrochlore type, but its synthesis mechanism is not clear, no direct evidence to determine the reaction precursor, study needs further. The presence of an acidic environment with a variety of tungsten ions and more heteropolyacid ion, and the transformation of the structure of the situation is complex and varied, this article focuses on the basic system of tungsten oxide pyrochlore-type hydrothermal synthesis mechanism.

Pure sodium tungstate solution for the reactants, hydrochloric acid as an additive, in an alkaline environment pyrochlore type hydrothermal synthesis of tungsten oxide. Use FT-IR analysis of the infrared spectra of the test method change under different rules and acidification of the reaction solution Na2WO4 different time period, to analyze WO2-4, W7O6-24, H2W12O10-42 and W2O2-7 whether to prepare tungsten oxide pyrochlore-type reaction precursors, ruled out the use of exclusion H2W12O10-42, W2O2-7 possibility before the reaction the body as that of the precursor should WO2-4 and W7O6-24, and assisted by thermodynamic calculations prove.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Analysizing Tungsten Oxide Pyrochlore Type

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 15:28

Standard curve

A purity of more than 99.9% WO3 into a porcelain crucible, porcelain crucible and then placed in a muffle furnace and calcined at 800℃ 1 hour coolish placed in a desiccator, cool room temperature. Accurately weighed 0.25g tungsten trioxide into 100ml beaker, with 20% NaOH20ml, heating completely dissolved, after cooling into 250ml volumetric flask, dilute to the mark and shake, this solution was transferred to a plastic bottle dry spare.

Standard curve: accurate absorption 1.00mg / ml solution 0, 0.5, 1.0, 1.5, 2.0, 2.5, 3.0ml Guarantee 100ml flask were placed with 0.85N ~ NaOH complement to 10ml, plus 50 percent potassium thiocyanate 5ml, plus 1: 1HCL50ml, plus 1% TiCl32ml, diluted with water to the mark and shake for 10 minutes, measured at 721 spectrophotometer extinction 0.5cm cuvette with a wavelength of 420 nm, as a reagent blank reference, drawing working curve, the measured slope of the curve K.

Solid phase analysis

Weigh a sample in 50ml of 0.200 ~ 0.500g iron crucible, adding sodium peroxide 4g, was stirred with dry round a glass rod, a small piece of filter paper Sassafras net glass rod, the filters were put in a crucible, in addition to the low temperature furnace H2O , add a muffle furnace at a temperature of 700 ~ 750 ℃ burn for about 10 minutes until pink, remove coolish, leaching into the 250ml beaker containing 100ml of hot water, and washed with water crucible, cooled to room temperature later, into 250ml volumetric flask, dilute to the mark, shake, filtration.Imbibe filtrate G2ml (tungsten oxide content may be) in 100ml volumetric flask, fill 0.85N sodium hydroxide to 10ml, following the same standard curve drawing methods.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Pyrochlore Type Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 15:28

Pyrochlore type oxide, tungsten mostly A bit deletion type of layered perovskite tissue, wherein a water molecule is formed directly in contact with the two-dimensional layer structure of tungsten by hydrogen bonding interactions between the layers. Chinese name is pyrochlore type oxide, tungsten foreign names Pyrochlore-type H2W2O7, Formula H2W2O7WO3 • 0.5H2O it for layered composites, sensing field, tungsten oxide calcined preparation.

1988 French Coucou, who first synthesized by soft chemistry type of pyrochlore oxide, tungsten, they (NH4) 10W12O41 • 5H2O as precursor glycol solution is heated in an acidic reflux get [(NH4) 2O] xW2O6, will its repeated washing in acid solution, and the resulting powder is heated to remove water at 100 ℃, which obtained pyrochlore type tungsten oxide powder.

It applies layered composite materials, sensing field, tungsten oxide calcined preparation. Greenstone focus of the present study is not fully oxidized tungsten, still unable to mass production, so many applications yet to be developed.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Pompon Structure Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 15:27

Because tungsten oxide has excellent physical and chemical properties and widespread concern researchers. They have been used to produce the electrochromic windows, infrared switch, write read rub optical devices, detect NO2, H2S, H2, NH3, O3 gas sensing components, as well as humidity and temperature-sensitive components. Meanwhile, tungsten oxide is a very good catalyst and high-temperature superconducting materials. In addition, recent studies have found that the tungsten oxide nanowires have many new properties and uses, such as excellent field emission performance, can be prepared as WS2 nanotube structure precursor.

Back in the 1950s, people began the study of tungsten oxide whisker, originally mixed gas of argon and water vapor in the 1000 ~ 1200 ℃ react with tungsten system. In recent years, there are many literature reports the preparation of one-dimensional nano material of the tungsten oxide methods, such as template method, calcined mesoporous precursor (WO-L) method, the organic solution synthesis method, a high-temperature oxidation method, and an infrared heating oxidation, etc. . In addition, high-temperature reaction of tungsten and SiO2 and WS2 and O2 respectively prepared miniature tree structure containing tungsten oxide nanorods and miniature pine tree containing micron tungsten oxide tubes and fibers. Although one-dimensional tungsten oxide nanomaterials prepared a lot, but there are generally complex process, small yield and other shortcomings. Therefore, it is necessary to further explore new and practical method of preparation.

By W powder and Ni (NO3) 2 • 6H2O in molybdenum reaction kit package prepared pompon micron scale structure of tungsten oxide. Velvet globular structure by a few hundred microns in length, an outer diameter of the tube 1 ~ 10μm micron and sub-micron diameter 100500nm fibers. X-ray diffraction and transmission electron microscopy analyzes showed that: the product is a good crystal structure along the [010] W18O49 growth direction of the monoclinic structure. These pompon structure of tungsten oxide by Vapor-Solid (VS) growth mechanism of formation because it has a huge surface area, has great prospects in terms of micro-sensitive semiconductor components.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Analyzing Conditions of VTO Hydrogen Reduction Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 15:27

VTO hydrogen reduction process conditions include: reduction temperature, the amount of loading the boat, push the boat speed, the flow of hydrogen, hydrogen and hydrogen-way humidity will now analyze the various factors in order to optimize the process conditions.

(1) reduction temperature. The reduction temperature from tungsten in purple key role in the restoration process, but also affect the temperature of the partial pressure of the dynamic process and hydrated tungsten volatile compounds. The reduction temperature is high, coarse, low temperature, can bypass WO2 of reaction, fine granularity.

(2) the amount loaded boat. How many boat loading capacity is mainly reflected in the material thickness, material layer on the external diffusion of water vapor resistance material thickness, high resistance to slow the proliferation of granularity is coarse, and vice versa.

(3) push speed. If you push the boat fast, VTO low temperature preheat temperature unevenness already pushed rapidly with moisture will lead to a substantial increase but can not be discharged, resulting in the formation of hydrated tungsten compound, resulting particles grow .

(4) the hydrogen flow. Increasing the hydrogen flow helps steam quickly, timely discharge, reduce or avoid the generation of hydrated tungsten, and strengthen the exchange of material. Flow, fine granularity, but not too big, too easy to bring out resulting in low recovery of materials and tube blockage.

(5) hydrogen humidity. Humidity is easy to generate hydrated tungsten compound, causing the particle size grew. When hydrogen dew point of -65 ℃ or less can be achieved dry hydrogen states.

(6) through hydrogen mode. Shun inverse hydrogen and hydrogen can be used to produce ultra-fine tungsten powder, and their advantages.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Purple Tungsten Preparation Of Nano-Tungsten Powder Reduction

- Details

- Category: Tungsten Information

- Published on Friday, 03 April 2015 16:01

Compared with yellow tungsten or tungsten blue, purple tungsten have: an elongated needle or rod crystal, large surface area, high activity, good ventilation, oxygen index and small series of excellent properties, it is particularly suitable for gas-solid reactions The condition can easily be restored, and the grain is not easy to grow. Therefore, purple tungsten raw material, by lowering the reduction temperature, slow push the boat speed and reduce the amount of equipment and increased boat traffic, such as hydrogen can be produced optimal conditions of quality nano tungsten powders.

Purple tungsten during the restore process, the powder particle size changes all the time, this change mainly from two aspects. On the one hand is a chemical vapor transport growth mechanism. Tungsten oxide and water vapor will generate a volatile hydrated contact tungsten oxide (WO2 (OH2) and the H2 reduction reaction, the reduction product has been deposited on the nucleation of the metal tungsten powder, so that the grain growth; on the other hand is a solid-phase chemical reaction mechanism as the reduction of local time and reducing gas increasing concentration, purple tungsten reacts with hydrogen gas-solid multiphase reduction reaction. On purple tungsten needle or rod-shaped crystals breed countless tiny uniform spherical tungsten oxide grain, purple tungsten with the removal of oxygen atoms gradual lattice rearrangement, and finally gradually transformed into beaded metallic tungsten powder.

Purple tungsten large surface area, high activity, oxygen index is small, permeability, and is most suitable for the preparation of nanoscale tungsten powder materials. Purple tungsten using conventional hydrogen reduction process, reduction by optimizing process parameters, capable of producing high-quality nano-tungsten powder. The preparation process is short, high stability, and no atmospheric emissions of CO2 gases, is an environmentally friendly production methods.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Measuring Tungsten Oxide Physical Characteristics

- Details

- Category: Tungsten Information

- Published on Friday, 03 April 2015 16:01

As we all know, the physical characteristics of the tungsten oxide include specific surface area, pore volume, pore size distribution. Ammonium tungsten bronze (ATB), hydrogen tungsten bronze (HTB), purple tungsten oxide (TVO) and blue tungsten oxide (TBO) four kinds of tungsten oxide powder, the use of adsorption / desorption isotherms can be a good measure of the oxide physical characteristics: BET specific surface area such as, micropore volume, the pore volume, pore size distribution and fractional dimension.

(1)TVO has a maximum in the pore volume, the minimum value of the fractal dimension, a very smooth surface, which is conducive to the discharge of water let into the hydrogen, it is beneficial to use a hydrogen reduction process producing ultrafine tungsten powder. However, because the minimum micropore volume, the largest average pore size, pore size distribution and the narrowest having a wedge hole, which is not conducive to the doping process.

(2)HTB has the largest pore volume, maximum value of the fractal dimension (meaning very rough surface), the smallest average pore diameter and have open at one end, closed end cylindrical pore model, this is it for the doping process desirable.

(3)ATB and TBO HTB are smaller than have micropore volume and specific mesopore volume smaller TVO, ATB have a slit-like pore model, TBO having a pore structure open at both ends, for the hydrogen reduction process is, ATB and TVO TBO are not ideal for the doping process it, ATB and HTB TBO are not ideal.

(4)For the hydrogen reduction process or are required to study the physical characteristics of tungsten oxide before the doping process.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Electrospinning Process is Applied to Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Friday, 03 April 2015 15:57

Electrospinning technology originated in the 1930s and 1940s. Electrostatic spinning apparatus comprises generally connected to each of the following three parts: a high voltage power supply, a small diameter needle and a capillary tube to collect spinning metal foil, graphite paper collection means.

High voltage power supply for applying a high electric field, so that the charged polymer droplets. Before spinning the polymer droplet collection means reaches solution will evaporate, leaving the crosslinked fibers on spinning collecting device. Needle tube, one end of the high-voltage electrode and the other end connected to the power supply connection collection device containing solution. Droplet surface with a charge of driving under the high pressure will produce the opposite of the surface tension force. With the enhancement of the electric field, the droplets become stretched from the needle by a semi-circular cone, known as the Taylor cone. Taylor cone in the form of droplets ejected from the needle, through the non-stabilized and drawn two processes, thus becomes long and thin, while, as the solvent evaporates, leaving the fibers charged in the After air-curing, arrived on the collection device. Electrospinning the fiber diameter is generally formed about 3nm ~ 1μm.

Electrospinning process can also be applied in the preparation of tungsten oxide. As with WCl6 tungsten source, PVP and DMF were prepared under conditions of 16kV a precursor fibers and prepared at high temperature tungsten oxide nanofibers gas sensing performance as polymer carrier and solvent. With PVB as a carrier by electrostatic spinning process to produce tungsten oxide nanowires have electrochromic properties.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com