Comparing BTO And VTO Hydrogen Reduction

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:48

Fine grain carbide due to its high toughness, high wear resistance and good high temperature strength, excellent performance in recent years, been increasingly widespread attention, the demand and applications continue to expand. Ultrafine tungsten powder, tungsten carbide powder is an important raw material for the production of fine-grain carbide powder particle size and uniformity strongly affect the performance of Carbide, how to produce a fine particle size and uniform ultrafine tungsten powder is made Take the key to ultra-fine grain carbide.

Performance tungsten oxide materials will directly affect the reduction behavior of tungsten powder and final product performance, therefore, the question about what kind of material most suitable for the production of ultra-fine tungsten powder materials science has always been of widespread concern workers. Although blue tungsten by hydrogen reduction process is currently taking the most widely used tungsten powder raw materials, as long as at low temperatures, dry hydrogen, high hydrogen flow conditions thin material layers, you can use hydrogen reduction process for the production of tungsten blue ultrafine tungsten powder, but too high hydrogen flow rate and the material layer is too thin will lead to increase in cost. Purple tungsten in recent years to develop a tungsten oxide product, its phase component WO2.72 or W18O49, due to its unique properties, in the production of ultra-fine tungsten powder reflects its superiority, many materials and metallurgy scholar have carried out their research.

Under the same conditions, the comparison of the performance difference between blue and purple tungsten tungsten production of hydrogen reduction of tungsten powder. The results show that: Compared with blue tungsten, tungsten powder size purple tungsten produced finer and more uniform, and tungsten powder particle size less affected by the amount of loading boats and hydrogen flow. And from the microscopic structure and mechanism of hydrogen reduction of raw materials analyzes the causes of both tungsten powder raw materials to produce different size and uniformity of the difference.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Blue Tungsten Oxide And Purple Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:44

At present, the production of ultra-fine tungsten powder, use purple tungsten and tungsten blue two kinds of raw materials exist simultaneously, and therefore these two materials were compared, hydrogen reduction experiments under the same conditions, compare the restored tungsten powder particle size and uniformity of the difference to determine exactly what kind of material is more suitable for the production of ultra-fine tungsten powder. From the microscopic structure and the reduction mechanism of both raw materials analyzed two kinds of raw materials caused by the tungsten powder particle size reduction of hydrogen production and uniformity of the reasons for the differences.

Tungsten oxide reduction process, the particle size will usually change. Currently, the main theoretical explanation W powder particle size reduction process variations have two:

1) growth mechanism of chemical vapor migration. Tungsten and their oxides in contact with steam, will generate a volatile hydrated tungsten oxide (WO2 (OH) 2), evaporated to a homogeneous gas phase reduction reaction occurs with the H2, the reduction product of metal tungsten has been deposited on the nucleation of on the grain, so that the tungsten powder particles grow. This process is the reaction rate, the reduction product forms and materials will change significantly compared.

2) solid-phase local chemical reaction. Solid tungsten oxide contact occurs with H2 gas - solid reaction of oxygen atoms with the gradual removal of lattice rearrangement. This process is slow reaction rate and the reduction product form does not send

Health changed.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Preparing Ultra-Fine Purple Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:39

In recent years, ultra-fine particles as a new material, which is widely applied, ultrafine tungsten powder and tungsten carbide powder as raw material for the production of ultra-fine grain carbide has also been of great concern to the metallurgical workers. Domestic and foreign production of ultrafine tungsten powder or tungsten carbide powder were a lot of research [. Currently, the preparation of ultrafine tungsten powder has three main research directions: one to the existing blue tungsten based on the improvement process; the second is the use of the new reduction methods, such as hydrogen halide reduction; the third is the use of laser, fluidized and other new technologies.

On the use of APT for raw materials, preparation of fine particles of the active hydrogen reduction of tungsten oxide in wet hydrogen conditions - Purple tungsten process was studied. The results showed that the formation conditions of tungsten and purple reduction temperature, hydrogen humidity, heating rate, raw size, material thickness and other factors, purple tungsten particle size reduction with increasing temperature, humidity, and temperature increase rate of hydrogen gas, the raw material size and the material thickness increases. With APT (10μm) as raw materials in pH2O:pH2 = 1.7:1,2h the temperature rose to 1173K, 1173K incubated at 1.5h in the conditions obtaining direct reduction purple tungsten grain size of 2.2μm.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Preparing Ultrafine Tungsten Powder By Purple Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:35

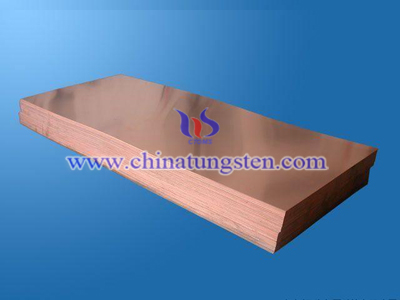

Before the 1950, at home and abroad tungsten powder production to more acid and yellow tungsten raw materials for production, to 60 to 70 years, the United States, France, the Netherlands, the United Kingdom and many other countries, has generally adopted a blue tungsten acid as raw materials to replace the production of tungsten and tungsten yellow powder. In the late 1980s and early 1990s, has been completely replaced with tungsten blue and yellow tungsten acid to produce tungsten powder, so now when using the traditional process of ultrafine WC powders, the choices are basically oxide precursor Blue tungsten. Another new purple tungsten tungsten oxide, its physical indicators than blue tungsten has some improvements and enhancements, blue tungsten is a more than suitable for the production of ultra-fine powder and WC W oxide precursor powder.

Choose purple tungsten as a raw material in the traditional process conditions, can get good performance ultrafine W powder, resulting in high-quality ultrafine WC powder. Purple Tungsten W is a production of ultra-fine powder and WC powder oxide precursor fit. Use purple tungsten materials prepared for WC particles of small size and uniform particle size distribution and good, no structural gathered clumps, WC complete crystalline grains. Purple tungsten raw material, whether it is produced by W powder or WC powder, its physical properties are superior materials for blue tungsten products.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Purple Tungsten Phase Component Reduction Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:30

Violet tungsten phase component WO2.72 (or W18O49), purple tungsten (TVO) powder having a maximum of pore volume, a minimum micropore volume, the narrowest pore size distribution, the smallest and the largest fractal dimension average pore diameter, which Hydrogen Reduction in favor of ultra-fine tungsten powder, to the detriment of the doping process, is a unique crystal structure so used to produce fine powder and fine tungsten carbide powder.

Performance is mainly determined by the quality carbide WC powder. The final grain size of the WC powder grain largely by reduction of the metal tungsten powder determined, while the grain is made of metal tungsten powder and tungsten oxide reduction condition is determined. Therefore, performance and purple tungsten oxide reduction process can affect the performance of tungsten and tungsten carbide powder, which ultimately affect the quality of the carbide.

Restore purple tungsten (V- tungsten oxide or WO2.72), the reduction of the product in different temperature ranges were under scanning electron probe to observe the phase composition seen in the temperature range of 885 ~ 900 ℃: the purple tungsten as raw materials in the reduction The key process tungsten dioxide reduction process is not controlled tungsten powder (T-W) particle morphology; process without passing through the tungsten (WO2) dioxide generated intermediate stage, can produce ultra-fine or micrometer tungsten, tungsten carbide powder .

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Purple Tungsten Oxide Use

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:26

Purple tungsten oxide (VTO), also known as purple tungsten oxide (TVO). Purple tungsten oxide is produced in the partial ammonium tungstate calcination process, different manufacturers of different purple tungsten oxide content. It is not the sense of chemical compound, but by a different component composition, such as arsenic trioxide, tungsten copper, and a low content of tungsten trioxide. The relative content of these compounds depends on the tungsten oxide purple calcination parameters. Purple purple tungsten oxide is finely powdered crystals. It is the precise control of the temperature in the reducing conditions, the production of secondary acid generated during ammonia. Purple tungsten oxide is mainly used in the production of tungsten metal powder and tungsten carbide. Purple tungsten oxide can also be used to make ultra-fine tungsten powder and nano tungsten powder.

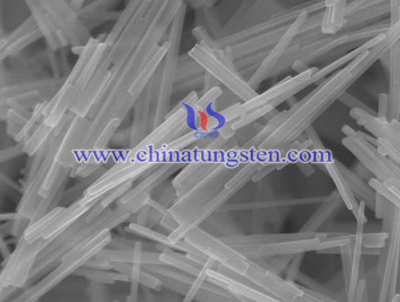

Morphology of the most special purple tungsten, loose particles in each group by a needle or rod-like particles composed of grains, grain structure of this great gap, tungsten powder generated when hydrogen nuclei to restore more, fast response, fine grain size, suitable for the production of fine particles of tungsten powder. With purple tungsten as raw materials in the reduction process without tungsten dioxide (WO2) generated intermediate stage, can be prepared from ultrafine or nano tungsten, tungsten carbide powder. Purple tungsten oxide itself has a unique form of fine needle-like crystals, which aggregate loose sponge-like, compared with the yellow tungsten and tungsten blue, purple tungsten oxide tungsten bulk density than the yellow, blue tungsten is much smaller, BET The minimum surface area, the chemical activity of the largest tungsten powder generated during hydrogen reduction fastest, most fine granularity, and purple tungsten oxide produced tungsten powder particle size and particle size distribution is quite stable. By Purple tungsten oxide W18O49 for raw materials tungsten powder, tungsten carbide powder with a small and easy to grow uniform characteristics. Purple tungsten oxide WO2 • 72 prepared by hydrogen reduction of tungsten powder fine and uniform dispersion of the particles between the good, is suitable for the preparation of an ultra-fine grain cemented carbide raw materials.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Producing Purple Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:24

How metal powder made of?

The first step is the manufacture of metal powder metallurgy. Powder production process consists of four steps: a solid-state reduction, atomization, electrolysis, and chemical methods. Solid state reduction

Reduction in solid powder reduction process, the selected ore crushing, mixing reducing substances (eg: carbon), transferred to the continuous furnace. All non-metallic materials and separation, screening, production of powder in the reaction furnace, leaving spongiform metal, then pulverized. Since there is no refining treatment, depending on the purity of the powder material. Irregular spongy particles, soft, easy compression, a good pre-sintered ("green") strength.

Atomization

In this process, the molten metal into small droplets and rapidly frozen before contact with each other or with a solid contact. Typically, the film flow of molten metal by gas or liquid high energy impact jets and decomposition. In principle, this technique is applicable to all metals can be melted and used for commercial production of metallic iron, copper, steel, brass, bronze, low-melting-point metals, such as aluminum, tin, lead, zinc, cadmium, as well as in selected case, tungsten, titanium, rhenium, and other high melting point materials.

Electrolysis

By selecting appropriate conditions, such as the electrolyte composition and concentration, temperature and current density, many metals can be cotton or powder state storage. Further processing, washing, drying, reduction, annealing, broken, is often required, ultimately produce a high purity, high density of the powder. Electrolytic copper is a metal raw material, but the iron, chromium, magnesium powder produced in this way can also be used. Due to its associated high energy costs, the electrolysis is generally limited to high-value powders such as high conductivity copper.

Chemical Methods

The most common process involves a redox chemical powder from the solution, precipitation, thermal decomposition. The performance of the powder produced a great change, but the powder particle size and shape basically similar. Redox powder tends to "sponge" shape, because there are many pores on the particle. The precipitated powder solution narrow particle size distribution, a high purity. Thermal decomposition is the most commonly used for treatment of metal carbonyls. These powders, after a grinding and annealing, a purity of over 99.5%.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Purple Tungsten Production Principle and Characteristics

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:20

Purple tungsten oxide is a different form of tungsten oxide, tungsten, has a unique crystal structure and other tungsten oxide (blue tungsten), its performance is also very different. Blue tungsten large particles have sharp edges, gathered together by a small cube, in varying degrees of broken surface, and covered with cracks; morphology purple tungsten is significantly different from the other three, each Large particles are needle-like or rod-like grains of loose particles group. All of the tungsten oxide pellets.

Purple tungsten oxide production in general is ammonium paratungstate (APT) as raw materials in industrial rotary furnace bamboo, under certain conditions (such as access NH3) were calcined, due to the decomposition of NH3 H2, so that APT mild reducing atmosphere calcined gradual decomposition of tungsten oxide reduction generated purple. The total chemical reaction equation is as follows: 3 [5 (NH4) 2O • 12WO3 • 5H2O] = 2w18O49 + 40H2O + 35H2 + 15N2.

Characteristic purple tungsten oxide products, tungsten oxide appearance usually pale purple purple or blue-purple. Purple major components and physical properties of tungsten oxide, and its bulk density between 1.9 to 2.3, the oxygen index ≦ 2.72, specific surface between 1.3 to 3.0.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Purple Tungsten Oxide Chemical Property

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:17

Purple tungsten oxide (Violet Tungsten Oxide, VTO), referred to as purple tungsten. Purple tungsten oxide refers to paratungstate (Ammonium Paratungstate, APT) as raw material was calcined under certain conditions, decomposition, reduction generated purple tungsten oxide. General purple or blue-purple crystalline powder. By strong fissile octahedral structure, intrinsic crystalline needle and rod. Purple Tungsten is a tungsten oxide, the chemical formula for WO2.72 or W18O49. Purple and yellow tungsten oxide, tungsten (the yellow tungsten WO3), blue tungsten oxide (referred to as blue tungsten W20O58 or WO2.90) and brown tungsten oxide (WO2) collectively known as tungsten oxide. The tungsten oxide can be used as raw material for the production of tungsten powder, tungsten because of its unique nature purple to purple tungsten tungsten powder products as raw materials, has generated fast, fine-grained and so on.

Purple tungsten oxide is pure secondary ammonium tungstate reaction under argon, then the Purple tungsten oxide deoxy prepare tungsten powder particles. (Purity: 99.99%, dewpoint -40℃), tungsten powder oxidized in the air. Tungsten oxide and tungsten powder is reduced in hydrogen, the sample was placed in a laser particle size distribution measuring instrument and the field emission scanning electron microscope, can exhibit its properties. Through two cyclic oxidation and reduction of three, will be ultrafine tungsten powder. Particle size distribution of ultrafine tungsten powder 0.1 μm to 1.0 μm is between 95.73%.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Purple Tungsten Oxide History

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:15

Purple tungsten oxide (Violet Tungsten Oxide, VTO), referred to as purple tungsten. Purple tungsten oxide refers to paratungstate (Ammonium Paratungstate, APT) as raw material was calcined under certain conditions, decomposition, reduction generated purple tungsten oxide. General purple or blue-purple crystalline powder. By strong fissile octahedral structure, intrinsic crystalline needle and rod. Purple Tungsten is a tungsten oxide, the chemical formula for WO2.72 or W18O49. Purple and yellow tungsten oxide, tungsten (the yellow tungsten WO3), blue tungsten oxide (referred to as blue tungsten W20O58 or WO2.90) and brown tungsten oxide (WO2) collectively known as tungsten oxide. The tungsten oxide can be used as raw material for the production of tungsten powder, tungsten because of its unique nature purple to purple tungsten tungsten powder products as raw materials, has generated fast, fine-grained and so on.

Purple tungsten oxide is a tungsten oxide. Purple tungsten oxide history can be traced back to produce tungsten oxide. Tungsten has a long history, dating back to the 18th century. It was first discovered by Peter Woulfe. Tungsten first to be called wolfram, element symbols for W. Swedish chemist Carl Wilhelm Scheele discovered scheelite, and its been a lot of research. In 1841, chemist Robert Oxland developed a production of tungsten trioxide and the first step of sodium tungstate. He was awarded a patent. Soon after, he is considered the founder of tungsten chemical systems.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com