Carbide Tool Coating Structure Classification

- Details

- Category: Tungsten Information

- Published on Thursday, 09 April 2015 14:28

Carbide tool coating structure classification can be divided into hard coated tool and soft coated tool,depending on the nature of the coating material. According to the different coating methods, the classifications include PVD and CVD.

(1) Single coating structure: also known as the conventional coating, the thin film is made into a particular compound or solid material.

(2) Multi-layer coating structure: adopting multi-layer methods, taking advantage of single-layer coating method and showing extra efforts in improving performance regarded to micro-hardness, high-temperature oxidation resistance and so on.

(3) Graded coating structure : successfully control the crack, gradually expanded its internal trends , while minimizing thermal stress , preventing the material from the surface to the base of cracks caused by failure of the expansion , improved defect carbide tools .

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Tool Manufacturing Processes

- Details

- Category: Tungsten Information

- Published on Thursday, 09 April 2015 14:25

The manufacturing process of tungsten carbide tool has the following three steps:

1.Preparation of carbide tool shank, which is that a compact is welded with carbide shank by high frequency induction brazing process;

2.Edge forming of carbide tool, which is that shank is formed into carbide tool of certain structural parameters by using WEDM technique;

3.Edge sharpening of carbide tool, which is that edge is improved by precision grinding technology to enhance the durability of the carbide tool and remove WEDM metamorphic layer.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Carbide Tool Strength

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 April 2015 19:51

Compressive Strength

Compressive strength is measured by compressing a right cylinder test piece between two tungsten carbide blocks held in line by an outer sleeve assembly. The CS of Tungsten Carbide is higher than for virtually all metals and alloys. This high compressive strength makes it possible to compress carbon at one million P.S.I. from man made diamonds.

Impact Strength

This measures the resistance of tungsten carbide to shock loading by a drop weight impact test. This is a more reliable indication of toughness than TRS readings.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Tool Grain Size

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 April 2015 19:49

The majority of tungsten carbide tool grades are made with standard size grains varying between 1 and 3 microns in size. Using larger grains of 2 - 6 microns will greatly increase the strength and toughness of the material because the larger grains interlock better. The trade off is that larger grain materials used by tungsten carbide tool do not offer as much resistance to wear as finer grain sized materials. Sub micron materials that vary between 0.4 and 1.0 micron grain size are harder than standard grain materials with the same cobalt content. The sub micron grains are much more uniform in size and hence give improved hardness as well as increased carbide strength. However, as specs show the transverse rupture strength is perhaps 20% improved on 15% sub micron compared to 15% fine grain material but this can give a false impression as sub micron carbide is not as resistant to impact and may chip more easily.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Tool Sharpening Instructions

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 April 2015 19:47

Tungsten carbide tools sharpening instructions are listed as follows,

1.Determine if your tool needs sharpening. One easy way to decide if your tool is becoming dull is to see if it reflects light well. Shine is an indication of wear. You can also gently scrape a fingernail on a blade and see if it shaves off a sliver; if it does not, the blade is dull. Touch is not necessarily a good way to determine if a blade is sharp, as a dull carbide tool may still feel sharp.

2.Find a professional sharpening service. Sharpening carbide is not recommended for non-professionals, as it requires skill and specific sharpening machinery. Imprecise sharpening can ruin a tool, and a professional can restore a blade to like-new condition.

3.If you are interested in learning how to sharpen blades yourself, it is recommended that you locate a teacher.

4.Carbide tools require diamond for sharpening, due to their hardness. Wet grinding using an abrasive wheel on an automatic grinder is a very precise method of sharpening. It is also possible to sharpen a tool by using a diamond lap, but this is very imprecise and time-consuming.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cryogenically Treated Tungsten Carbide Tools in Milling Operations

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 April 2015 19:43

The tungsten carbide cutting tools are now in common use in industry and cryogenic treatment has been acknowledged by some as a means of extending the tool life of many cutting tool materials, but little is known about the mechanism behind it.When the differences in tool performance between cryogenically treated and untreated tungsten carbide tool inserts during the high-speed milling of medium carbon steel indicate that cryogenically treated tools exhibit better tool wear resistance than untreated ones. Also, it is evident that the application of coolant during cutting helps to reduce tool wear experienced by the cryogenically treated tools even further. In addition, cryogenically treated tools are found to perform best under a particular set of cutting conditions.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ti-base Tungsten Carbide Tools Advantages

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 April 2015 19:41

Hard coating deposition by physical vapor deposition (PVD) such as TiN and TiCN have several advantages in tools application market, the main benefits can be listed as follows,

Hard coating depositions have high hardness, low wear coefficient and chemically inert nature of their surfaces against wear and corrosion, which largely influence the high-speed cutting technology develops.

Different from traditional coolants, Ti-base tungsten carbide end mills tools are environmental friendly and present no harm to human health. Moreover the lower disposal cost of this kind of tools also making effort in discreasing relevant manufacuring cost.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide End Mills Tool Life

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 April 2015 19:39

With the comparison of the tool life of tungsten coated by multi-layer TiCN and TialCN for end mills using Taguchi method indicates that the main factors of affecting tool life are different coated deposition, feed rate, spindle speed and tool material. And the tool material is the most critical influence in tool life in milling.In terms of the different coated deposition, the TiCN one has the best performance. When the coating deposition matches tool material the effect of hard coating deposition is small. Moreover the hard coating deposition can improve the wear problem on the tool surface and bring up the best wear resistance during the machining.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How Prepare Pyrochlore Type Tungsten Oxide ?(二)

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 April 2015 17:10

Current hydrothermal method has been widely used in the synthesis of inorganic materials and material handling, compared to other methods have many advantages: a relatively simple equipment required for the reaction, and water and heat control has significant operational and adjustable degeneration; hydrothermal method particularly suitable for the synthesis of a special structure, a new specialty compounds and concentrations of condensed matter, rules-oriented and crystalline perfection of preparing a crystalline material balance defects; under hydrothermal conditions, the solution viscosity decreased, diffusion and mass transfer process more smoothly, active reactant has greatly improved, and thus can replace some of the hydrothermal synthesis temperature solid phase reaction, and promoting, the development of low-temperature synthetic chemistry.

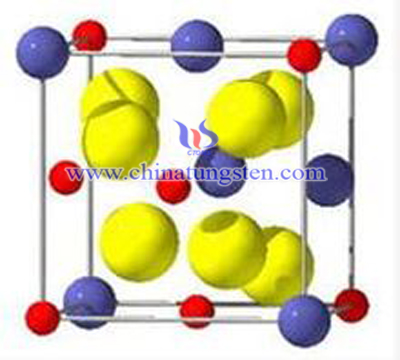

In 1989, Sweden's Amberg, who for the first time by hydrothermal prepared a pyrochlore type tungsten oxide cubic system, the phase is a hydrothermal method in the study of pH = 3.0 synthetic magnesium tungstate in occasional crystals obtained using, parsed too known to be W2O6 • H2O (ie H2W2O7). Kenneth et al., 1992 reported a more detailed preparation conditions of the hydrothermal synthesis of crystalline tungsten oxide and its relationships, found in a pH range of 3.5 to 4.5 is obtained pyrochlore-type structure, at a pH of between 1.3 to 2.0 The resulting structure is hexagonal. Whereas at pH between 2.0 to 3.5 to obtain a pyrochlore type and hexagonal mixed phase, if the pH is greater than 5 are not precipitate the product. Guo et al., 1995 by hydrothermal synthesis using HCl to adjust the pH value of 6.0 was also prepared a pyrochlore-type oxide, tungsten, and the material has good electrochemical characteristics, indicating that factors pyrochlore type hydrothermal synthesis of tungsten oxide Many, wherein the pH of the environment is likely to be the most important factor.

Research on China Hydrothermal Method tungsten oxide pyrochlore type rarely, the method is slightly different: Within a pH range of 2.5 to 4.5 is obtained pyrochlore type superfine powder of pure tungsten oxide phase at pH get between 0.5 and 2.0 is hexagonal tungsten oxide. Studies have shown that while in the temperature range of 130 ~ 200 ℃ of the prepared powder grain size difference is not more than 5nm, the temperature can increase the grain size is slightly reduced, but little effect on the concentration of hydrochloric acid used in grain size. Powder aggregates mainly in the form of, EP-MA morphology shown in Figure 2, show the particle size analysis, the powder particle size 2 ~ 100μm bimodal distribution between the average particle diameter is large, and the powder for one month After the reunion phenomenon is more pronounced.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How Prepare Pyrochlore Type Tungsten Oxide ?(一)

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 April 2015 17:10

Soft chemical synthesis under mild conditions, i.e. synthesis of inorganic functional material, or it is sought in the solution to a low temperature starting reactants are uniformly mixed on the molecular size, a controlled chemical reaction after generation precursor or intermediate, the last generation with the specified composition, structure and morphology of the material. 1988 French Coucou, who first synthesized by soft chemistry type of pyrochlore oxide, tungsten, they (NH4) 10-W12O41 • 5H2O as precursor glycol solution is heated in an acidic reflux get [(NH4) 2O] xW2O6 , repeatedly washed in acid solution, and the resulting powder is heated to remove water at 100 ℃, which obtained pyrochlore type tungsten oxide powder. Li et al., 1996, using the same method for preparing a series of (M2O) xWO3 • zH2O (M = H +, Li +, Na +, Ag +, and NH + 4), and to test the performance of the series powder humidity.

These methods often can only get there missing pyrochlore lattice type tungsten oxide, and water molecules which content is generally less than a full H2W2O7. Soft chemical method developed in recent years are generally presented Aurivil-lius Bi2W2O9 as precursor compounds obtained tungsten oxide pyrochlore type by acid treatment. RESchaak and ManabuKu-do, who devised the method detailed preparation process: Bi2O3 and WO3 will follow after 1:2 molar ratio of mixed 48h calcined at 800 ℃, resulting Bi2W2O9 into concentrated hydrochloric acid, and then vigorously stirred at room temperature for 72h to obtain undistorted H2W2O7 crystals. After H2W2O7 the vast majority of studies are based on this approach.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.comTungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com