Producing Purple Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:24

How metal powder made of?

The first step is the manufacture of metal powder metallurgy. Powder production process consists of four steps: a solid-state reduction, atomization, electrolysis, and chemical methods. Solid state reduction

Reduction in solid powder reduction process, the selected ore crushing, mixing reducing substances (eg: carbon), transferred to the continuous furnace. All non-metallic materials and separation, screening, production of powder in the reaction furnace, leaving spongiform metal, then pulverized. Since there is no refining treatment, depending on the purity of the powder material. Irregular spongy particles, soft, easy compression, a good pre-sintered ("green") strength.

Atomization

In this process, the molten metal into small droplets and rapidly frozen before contact with each other or with a solid contact. Typically, the film flow of molten metal by gas or liquid high energy impact jets and decomposition. In principle, this technique is applicable to all metals can be melted and used for commercial production of metallic iron, copper, steel, brass, bronze, low-melting-point metals, such as aluminum, tin, lead, zinc, cadmium, as well as in selected case, tungsten, titanium, rhenium, and other high melting point materials.

Electrolysis

By selecting appropriate conditions, such as the electrolyte composition and concentration, temperature and current density, many metals can be cotton or powder state storage. Further processing, washing, drying, reduction, annealing, broken, is often required, ultimately produce a high purity, high density of the powder. Electrolytic copper is a metal raw material, but the iron, chromium, magnesium powder produced in this way can also be used. Due to its associated high energy costs, the electrolysis is generally limited to high-value powders such as high conductivity copper.

Chemical Methods

The most common process involves a redox chemical powder from the solution, precipitation, thermal decomposition. The performance of the powder produced a great change, but the powder particle size and shape basically similar. Redox powder tends to "sponge" shape, because there are many pores on the particle. The precipitated powder solution narrow particle size distribution, a high purity. Thermal decomposition is the most commonly used for treatment of metal carbonyls. These powders, after a grinding and annealing, a purity of over 99.5%.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Purple Tungsten Production Principle and Characteristics

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:20

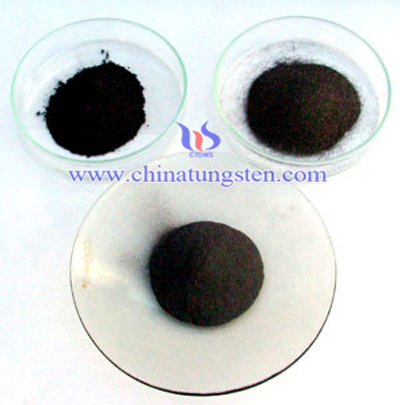

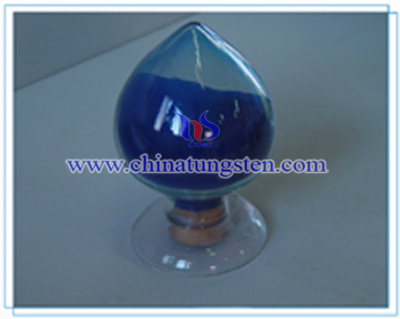

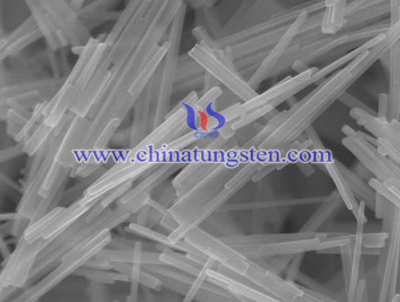

Purple tungsten oxide is a different form of tungsten oxide, tungsten, has a unique crystal structure and other tungsten oxide (blue tungsten), its performance is also very different. Blue tungsten large particles have sharp edges, gathered together by a small cube, in varying degrees of broken surface, and covered with cracks; morphology purple tungsten is significantly different from the other three, each Large particles are needle-like or rod-like grains of loose particles group. All of the tungsten oxide pellets.

Purple tungsten oxide production in general is ammonium paratungstate (APT) as raw materials in industrial rotary furnace bamboo, under certain conditions (such as access NH3) were calcined, due to the decomposition of NH3 H2, so that APT mild reducing atmosphere calcined gradual decomposition of tungsten oxide reduction generated purple. The total chemical reaction equation is as follows: 3 [5 (NH4) 2O • 12WO3 • 5H2O] = 2w18O49 + 40H2O + 35H2 + 15N2.

Characteristic purple tungsten oxide products, tungsten oxide appearance usually pale purple purple or blue-purple. Purple major components and physical properties of tungsten oxide, and its bulk density between 1.9 to 2.3, the oxygen index ≦ 2.72, specific surface between 1.3 to 3.0.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Purple Tungsten Oxide Chemical Property

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:17

Purple tungsten oxide (Violet Tungsten Oxide, VTO), referred to as purple tungsten. Purple tungsten oxide refers to paratungstate (Ammonium Paratungstate, APT) as raw material was calcined under certain conditions, decomposition, reduction generated purple tungsten oxide. General purple or blue-purple crystalline powder. By strong fissile octahedral structure, intrinsic crystalline needle and rod. Purple Tungsten is a tungsten oxide, the chemical formula for WO2.72 or W18O49. Purple and yellow tungsten oxide, tungsten (the yellow tungsten WO3), blue tungsten oxide (referred to as blue tungsten W20O58 or WO2.90) and brown tungsten oxide (WO2) collectively known as tungsten oxide. The tungsten oxide can be used as raw material for the production of tungsten powder, tungsten because of its unique nature purple to purple tungsten tungsten powder products as raw materials, has generated fast, fine-grained and so on.

Purple tungsten oxide is pure secondary ammonium tungstate reaction under argon, then the Purple tungsten oxide deoxy prepare tungsten powder particles. (Purity: 99.99%, dewpoint -40℃), tungsten powder oxidized in the air. Tungsten oxide and tungsten powder is reduced in hydrogen, the sample was placed in a laser particle size distribution measuring instrument and the field emission scanning electron microscope, can exhibit its properties. Through two cyclic oxidation and reduction of three, will be ultrafine tungsten powder. Particle size distribution of ultrafine tungsten powder 0.1 μm to 1.0 μm is between 95.73%.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Purple Tungsten Oxide History

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 16:15

Purple tungsten oxide (Violet Tungsten Oxide, VTO), referred to as purple tungsten. Purple tungsten oxide refers to paratungstate (Ammonium Paratungstate, APT) as raw material was calcined under certain conditions, decomposition, reduction generated purple tungsten oxide. General purple or blue-purple crystalline powder. By strong fissile octahedral structure, intrinsic crystalline needle and rod. Purple Tungsten is a tungsten oxide, the chemical formula for WO2.72 or W18O49. Purple and yellow tungsten oxide, tungsten (the yellow tungsten WO3), blue tungsten oxide (referred to as blue tungsten W20O58 or WO2.90) and brown tungsten oxide (WO2) collectively known as tungsten oxide. The tungsten oxide can be used as raw material for the production of tungsten powder, tungsten because of its unique nature purple to purple tungsten tungsten powder products as raw materials, has generated fast, fine-grained and so on.

Purple tungsten oxide is a tungsten oxide. Purple tungsten oxide history can be traced back to produce tungsten oxide. Tungsten has a long history, dating back to the 18th century. It was first discovered by Peter Woulfe. Tungsten first to be called wolfram, element symbols for W. Swedish chemist Carl Wilhelm Scheele discovered scheelite, and its been a lot of research. In 1841, chemist Robert Oxland developed a production of tungsten trioxide and the first step of sodium tungstate. He was awarded a patent. Soon after, he is considered the founder of tungsten chemical systems.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Paste Type Adjustable Fishing Sinker

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 April 2015 08:54

The utility model provides a tungsten paste type adjustable fishing sinker, which comprises an adjuster with an inner screw thread, and a sinker sleeve with a connecting rod.

A cavity defined by the adjuster and the sinker sleeve with the connecting rod is provided with metal paste, a through hole is formed in the sleeve wall of the sinker sleeve, the connecting rod is arranged in the adjuster, and the adjuster is rotated in the sinker sleeve to compress the mental paste and enable the mental paste to be discharged through the through hole. According to the adjustable fishing sinker provided by the utility model, the adjuster is rotated so as to stretch out and draw back, and then the goal of accurately adjusting a float is achieved by adjusting the quantity of tungsten paste in the cavity between the adjuster and the sinker sleeve with the connecting rod. In addition, the tungsten paste can be used repeatedly, does not pollute the environment, and is energy-saving and environment-friendly.

An adjustable tungsten mud fish catch, including: regulator with an internal thread and a fall jacket with a connecting rod, characterized in that the adjustment of the cavity with a connecting rod and said sleeve formed of fall built with a metal paste, the walls of the sleeve falling sleeve has through-holes, said connecting rod is disposed within said regulator, said regulator rotary compression sleeve falling metal sludge removed from the through-hole.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Preparing Ultrafine Tungsten Carbide By Purple Raw Materials

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 March 2015 17:36

Superfine carbide with high hardness and wear resistance, high strength and toughness and good high temperature properties, has been widespread attention, has become an important direction of development in the world today carbide. Superfine carbide cutting in difficult areas has been widely used, but also meet the needs of the rapid development of electronic technology for integrated circuit board drilling micro drill. Currently there are dozens of brands of ultra-fine carbide, since the study of ultrafine Carbide performance optimization has been ongoing.

Superfine carbide with high hardness, high wear resistance, excellent performance, ensuring ultra-fine carbide grain size small and uniform is a key factor in size small, evenly distributed ultrafine WC powder as raw material. During the preparation of ultrafine WC powder, commonly used materials for blue tungsten oxide, tungsten less to purple as the raw material preparation process coverage. Using the same process, respectively, blue and purple tungsten raw materials for the preparation of ultrafine tungsten WC powder, and uses the same process for the preparation of ultrafine tungsten carbide, for comparing the performance of both products, found in purple tungsten as raw material out Ultrafine carbide grain size, high strength and hardness has good overall performance.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Preparation Of Tungsten Oxide Hydrate Material

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 March 2015 17:34

Liquid crystals prepared as in ancient China's oldest crystal preparation, ancient people extracted salt from seawater process is instantiated crystal growth under conditions of liquid system. Production practice long time, and now liquid phase has been subdivided into a number of specific technical solutions use different types of crystal growth, and these technologies are still constantly evolving. Hydrothermal process is carried in an aqueous system, by changing the solubility of the crystal, the crystal growth system for liquid phase growth method.

(1) Reaction conditions: hydrothermal method commonly used water is mixed with other salts forming solvent (or become a mineralizer), and therefore during the reaction, such a system can be difficult to dissolve the material at ambient conditions (high melting point oxides, etc.) to improve their solubility, to promote the reaction under the reaction conditions usually higher at relatively mild conditions.

(2) the reaction environment: Hydrothermal reaction is controlled during the growth process of the crystal particles by controlling the reaction temperature and pressure. The growth process is usually carried out in a closed system environment, the. The closed environment is often used to maintain the autoclave, due to higher temperature, higher pressure such that the reaction system is very corrosive to steel to material, so more memory polytetrafluoroethylene material as the reactor lining material.

(3) reaction: with various other liquid phase method, a hydrothermal reaction process, the reactor is generally vertically disposed, and therefore part of the kettle liquid and vapor phases due to the presence of vertical temperature gradient distribution. The temperature gradient causes the liquid and gas phases inside the reactor intense convection occurs in the course of the reaction, the liquid moved by the high-temperature region to migrate to lower temperature, and phase transition accompanied by changes in local excessive solution saturation at low temperature District because the solution becomes supersaturated solute precipitates to form a precipitate, gasified liquid back into a cold solution of the liquid phase, repeated cycles of convection, the solute precipitates will eventually grow to form crystals.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Thick Tungsten Oxide Gas Sensors Modified Atmosphere

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 March 2015 17:32

Screen printing method using tungsten oxide powder was prepared by acid decomposition into thick tungsten oxide gas sensors, and has carried out the reduction and oxidation treatment in an atmosphere of hydrogen and air, systematic study of hydrogen concentration and temperature on the rate of oxidation sensitive membrane morphology, structure and CO gas sensing performance. The results showed that the hydrogen reduction - after air oxidation, the sensitive film surface morphology by approximately spherical particles into the rod-shaped or cluster rules smooth surface quadrangular prism open at both ends, while the crystal structure is not changed. Sensitive membrane of CO sensitivity (Rair / RCO) with increasing concentration of CO and the test temperature is higher. Compared with the no sensitive membrane modified atmosphere, reducing atmosphere by 10% H2 in air to 600 ℃ sensitive membrane after 5 ℃ / min oxidation of CO with maximum sensitivity, it is to 3.8 × 10-5CO 13.3-fold increase in sensitivity. Sensitive membrane through modified atmosphere can significantly improve the sensitivity of CO can.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Ion-Sensitive Membrane

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 March 2015 17:24

The tungsten oxide film is one of the most compelling ion-sensitive color material having ReO: structure, the crystal structure is actually the ABO3 type perovskite structure in the vacant cation sites A and B into bit W6 +. When there is a positive ion source, plus the electric field will cause positive ions M and electron diffusion and migration in WO3 films. When the WO. When the negative voltage is applied, positive ions are implanted WO3 film, occupy one bit "A" to form a tungsten bronze MxWO3; reverse voltage, the ions are implanted from the WO3 film and the extraction process of extracting the ion implantation is a reversible electric. chemical reaction process.

Ion implantation with the extraction process of the tungsten oxide film, the optical properties of the film (light transmittance, reflectance, absorption rate and refractive index, etc.) and electrical properties will undergo significant changes. For example, as the ion implantation amount X increase, MxWO3 be changed from a semiconductor or insulator having metallic properties, the resistivity can vary from 6 to 01 a occurs in 5X01`ncm range. Accordingly, the film will be in a transparent state (visible light transmittance> 08 W) to dark blue color (visible light transmittance <02%) reversible change between .WO: effect of this ion-sensitive color film in the optical switch smart window (SmratWindow), information displays, gas sensors, pH probes and other fields have broad application prospects.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Nanomaterials Application - Humidity Sensor

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 March 2015 17:21

Humidity detection and control in microelectronic circuit processing, indoor intelligent control, pharmaceutical, biological samples cultured greenhouse crop cultivation and other fields have extensive application, precise and accurate monitoring of the role and influence of moisture and humidity sensors promote the intensified research, people design and development of a variety of devices to improve and enhance the performance of the methods and techniques. Humidity sensor is generally conductive material change in the nature of variation of the adsorption of water molecules according to the physical and chemical properties of the surface of the design process. Based on a variety of mechanisms to respond, divided into capacitive humidity sensor, resistive type, photoelectric type, and gravity type.

Advances in integrated SAW humidity sensor humidity sensor research and nano tungsten oxide, with bifunctional ligand ammonium small molecule organic coating agent to do to prepare low-dimensional tungsten oxide nanocrystals as a sensitive film, combined with the excellent performance of SAW moisture detection devices, this is a relatively new and interesting perspective, in order to further explore the performance optimization and humidity sensor properties of nanocrystalline tungsten oxide to improve the intrinsic link between the two.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com