Tungsten Alloy Discs: The Ideal Material in the Counterweight Field

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 September 2025 11:40

In modern industrial and technological fields, the use of high-density materials has become a key factor in enhancing equipment performance and safety.

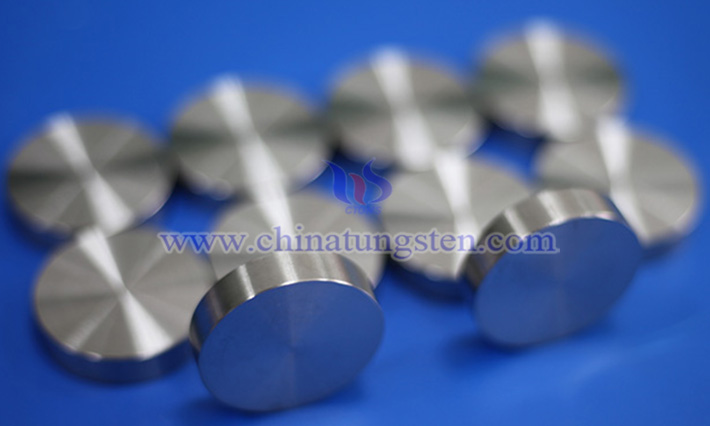

Among these, CTIA GROUP LTD tungsten alloy discs stand out as a high-performance alloy material due to their unique physical and chemical properties. Tungsten alloys, typically alloyed with tungsten (W) and elements such as nickel (Ni), iron (Fe), or copper (Cu), boast a density of 16.5–18.75 g/cm³, significantly higher than traditional counterweight materials like lead (11.34 g/cm³) or steel (7.8 g/cm³), while offering excellent corrosion resistance, high strength, and good processability. These characteristics make tungsten alloy discs particularly suitable as counterweight components for balancing vibrations, optimizing dynamic stability, and saving space.

The counterweight field spans industries such as automotive, aerospace, military, sports equipment, and industrial machinery, with the disc-shaped design of tungsten alloy discs facilitating easy installation and adjustable mass distribution.

Applications of CTIA GROUP LTD Tungsten Alloy Discs

Applications in the Automotive Industry

The automotive industry is one of the most extensive application areas for tungsten alloy discs. As vehicles transition toward high performance and electrification, the demand for dynamic balance and vibration control has become increasingly critical. The high density of tungsten alloy discs enables counterweighting in limited spaces, avoiding the volume expansion issues associated with traditional lead weights, thereby optimizing vehicle design.

In tire balancing, high-speed rotating tires can generate vibrations, leading to uneven wear and unstable driving. Tungsten alloy discs, applied via adhesion or embedding in the rim, achieve relative balance. Engine crankshafts, subjected to significant centrifugal forces during high-speed operation, benefit from tungsten alloy discs as counterweights at the ends, effectively balancing vibrations and extending component lifespan. Additionally, tungsten alloy discs play a key role in vibration damping and chassis weight control. In suspension systems, dampers absorb road impacts, and tungsten alloy discs, as high-density counterweights, optimize center-of-gravity distribution, reducing noise and vibration transmission.

Applications in the Aerospace Industry

The aerospace industry demands high material density and stability, with tungsten alloy discs primarily applied to balance flight control and power systems. Spacecraft and aircraft operate under extreme conditions where any imbalance could lead to catastrophic consequences. The high specific gravity, high melting point, and fatigue resistance of tungsten alloys make them an ideal counterweight choice. In aircraft control surface counterweighting, tungsten alloy discs are used in rudders, flaps, and ailerons to adjust the aircraft’s center of gravity and flight posture.

Applications in the Military Field

Military applications emphasize high density and impact resistance, with tungsten alloy discs playing a critical role in missiles, aircraft carriers, and military equipment. Their high hardness and heat resistance make them suitable for combat environments. In missile and aircraft carrier counterweighting, tungsten alloys are used in control surfaces and inertial systems to provide balance and improve equipment precision. Additionally, in military vehicles and equipment, tungsten alloy discs are employed for chassis and turret counterweighting.

Applications in Sports Equipment

In the sports equipment sector, tungsten alloy discs are valued for their convenience and balance, helping athletes optimize performance. Their eco-friendliness and durability have made them a mainstream replacement for lead weights. In golf club head counterweighting, tungsten alloy discs embedded in the rear of the head adjust the swing center of gravity, enhancing ball distance and accuracy. In deep-water fishing, tungsten alloy sinkers provide stable descent, resisting water currents and improving catch rates. In archery equipment, tungsten alloys are used for bow arm counterweighting, stabilizing shooting posture and reducing vibration. Furthermore, in tennis and badminton rackets, tungsten alloys serve as handle or frame counterweights, improving balance and shock absorption.

Applications in Industrial Equipment and Shipbuilding

In industrial equipment, tungsten alloy discs are widely used in balancing systems for heavy machinery to ensure efficient operation. High-density tungsten alloy discs save space in elevator cables, providing stable balance. Computer disk drives and oil well logging equipment leverage their precision to maintain stability in rotating components, supporting deep-well operations. In the shipbuilding industry, tungsten alloy discs are used for stability counterweighting, helping maintain hull balance under high waves and enhancing navigation safety.

Applications in Other Consumer Products

In watches and optical equipment, tungsten alloy discs serve as small counterweights to adjust balance, ensuring stable operation.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com