Applications of Tungsten Alloy Discs in the Target Field

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 September 2025 17:15

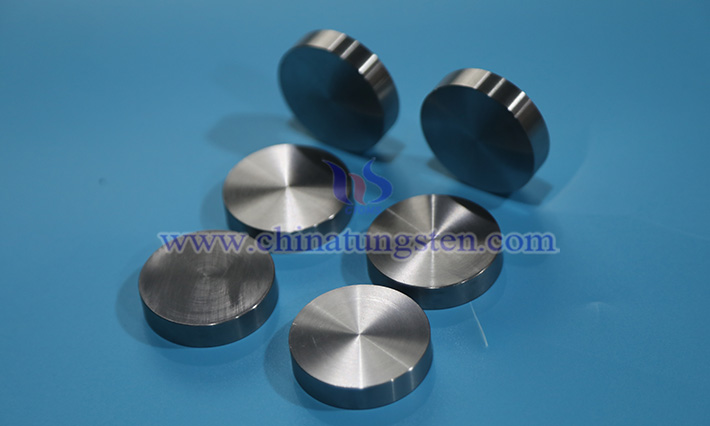

CTIA GROUP LTD tungsten alloy discs are typically made by alloying tungsten with nickel, iron, titanium, or other elements. Their exceptional performance stems from their unique material composition and microstructure, making them widely used in the target field. Industrial-grade tungsten alloy discs generally have a purity of 99.95% or higher. While pure tungsten targets offer high density and excellent high-temperature resistance, their brittleness makes them prone to cracking during processing. As a result, tungsten-based alloys such as W-Ni-Fe (tungsten-nickel-iron alloy, with tungsten content ranging from 85% to 99%) or W-Ti (tungsten-titanium alloy, with adjustable tungsten-titanium ratios) are commonly used. These alloys are produced via powder metallurgy, with tungsten particles uniformly dispersed in a metal binder phase, forming a dense structure.

High purity is a critical characteristic of tungsten alloy discs, influencing the stability of targets during sputtering and the quality of deposited thin films. Factors affecting the purity of tungsten alloy discs include: first, the purity of the raw powder—tungsten powder with a purity below 99.9% inevitably retains impurities such as oxygen, carbon, or silicon, leading to oxide inclusions in the alloy; second, environmental control during manufacturing—high-temperature processing can introduce oxygen contamination; third, impurities in other metal powders, such as trace sulfur or phosphorus in Ni or Fe powders, which amplify impurity effects.

What impact does purity have on targets? High-purity tungsten alloy discs reduce the release of impurity atoms during sputtering, preventing defects such as vacancies or inclusions in thin films, thereby improving the electrical properties of the films. Additionally, high purity enhances film adhesion and uniformity, avoiding localized overloading or peeling.

Furthermore, tungsten alloy discs exhibit excellent electrical properties, with low resistivity, making them suitable for depositing conductive films such as semiconductor gate layers.

I. Applications of Tungsten Alloy Discs in the Target Field

CTIA GROUP LTD tungsten alloy discs have perse applications in the target field, primarily in thin film deposition processes, driving advancements in multiple high-tech industries.

In the semiconductor industry, tungsten alloy discs are ideal targets for sputtering tungsten thin films. These films are commonly used in transistor gate electrodes, contact hole filling, and interconnect layers. For instance, W-Ti alloy discs can deposit Ti/W barrier layers, preventing Cu diffusion and enhancing device reliability.

In the aerospace sector, tungsten alloy discs are used for depositing high heat-resistant coatings. Rocket engine nozzles and turbine blades require high temperature resistance, and thin films formed by sputtering tungsten alloy targets provide effective thermal shielding and anti-oxidation protection. The high density of W-Ni-Fe discs enables deposited films to absorb impact energy, making them suitable for satellite structural components. Additionally, in MEMS (microelectromechanical systems) sensors, thin films formed by sputtering tungsten alloy discs enhance vibration and thermal stability, providing critical support for the miniaturization of aerospace probes.

Energy and renewable energy represent another key application area. Back electrode layers in solar cells often use tungsten alloy targets to deposit films, improving light absorption efficiency and weather resistance. In fuel cells, tungsten alloy discs are used to coat proton exchange membrane (PEM) catalyst layers, with their high conductivity and acid resistance extending battery lifespan.

In optics and display fields, tungsten alloy disc targets are used to deposit reflective films or anti-reflective coatings. For example, in laser mirrors, W-Ti films with low optical loss enhance light output efficiency. In high-end display screens, the uniform deposition of tungsten alloys in TFT (thin-film transistor) back electrode layers prevents leakage current issues.

Medical device applications are increasing. Tungsten alloy discs are used as targets in X-ray tubes to deposit high-density films, improving imaging resolution. In implantable devices, their biocompatible films reduce rejection reactions. In military applications, tungsten alloy target-deposited armor coatings leverage high hardness for enhanced protection.

II. Comparison of Tungsten Alloy Discs with Other Targets

Tungsten alloy discs surpass other alloy targets in density, melting point, and tensile strength, making them suitable for high-temperature, high-radiation, and heavy-load environments such as semiconductor barrier layers and nuclear industry coatings. However, their high processing difficulty and cost limit their use in low-cost or lightweight scenarios. In contrast, titanium alloy targets are known for their low density and good corrosion resistance, suitable for aerospace and medical implants but with weaker high-temperature resistance; aluminum and copper alloy targets are cost-effective with strong thermal conductivity, ideal for optical and conductive layers but lacking in mechanical strength and corrosion resistance; molybdenum alloy targets are close to tungsten alloys in heat resistance and density but fall short in radiation shielding and hardness.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com