Tungsten Carbide Cutting Tools Liquid Cooling Mechanism

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 March 2015 14:18

When cemented tungsten carbide cutting tools in addition to frictional heat generated inside the metal molecules within the tool and the shear plane will produce the frictional heat generation, so that cemented tungsten carbide cutting tools the cutting zone temperature can reach 600 ℃ ~ 800 ℃, so require cutting fluid must have good lubrication and cooling performance.

Tungsten carbide cutting tools in the cutting process, the cooling effect of cutting fluid is mainly from the cutting area is quickly taken away by pouring hot coolant to the cutting tool tungsten carbide cutting tools zone generated during cutting, reducing tungsten carbide cutting tools, the temperature of the workpiece, tool life, reduce the thermal deformation of the workpiece, reducing thermal stress and improve the durability of tungsten carbide cutting tools, machining accuracy. Cutting fluid cooling mechanism is: a way to penetrate into the friction area, the deformation zone to play the role of thermal cooling. Cooling of the cutting fluid and the thermal conductivity, specific heat, and the flow rate for the fluid lubrication and related methods, thermal conductivity, specific heat parameters of the better the greater the cooling.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Nano-Tungsten Oxide Thin Films Photoluminescence Application(a)

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 March 2015 14:17

Photochromic properties of tungsten oxide in the optical information storage, optical control, field optical switches, optical device materials, optical information such as genetic material has broad application prospects. Using photochromic properties of tungsten oxide system has been designed, and creating a lot of practical applications of the device, such as can be used to split water WO3 / TiO2 composite solar cells while having photochromic properties of wisdom electrochromic window (PV-ECsmartwindows).

The Optical Recording And Image Storage

When using light-induced photochromic compound by different wavelengths of light irradiation intensity and color characteristics of repeated cycles, which can be made from computer memory storage device, to achieve the elimination process and memory information. Recorded information density is very large, and good fatigue resistance, fast write and erase information. Amorphous WO3 being a KrF excimer laser wavelength for the next generation of laser irradiation will turn purple 248nm wavelength longer be produced Nd-Y-Al garnet laser for laser irradiation can become another 1.06μm colorless. The study also found that the use of WO3 changes in the optical properties of the annealing process characteristics made write-once optical recording disk, the data storage density of up to a maximum 25GB. Furthermore WO3 blue under UV irradiation can be used autoradiography photosensitivity holographic recording camera. Painted on transparencies WO3 thin film layer, which is not sensitive to visible light, into a colored image in the UV irradiation. This high resolution imaging method, operator error will not occur, and the image can be repeatedly recorded and eliminated.

Optical Tunable Photonic Band Gap Crystals

Photonic crystals are artificial dielectric constant in the spatial structure of a periodic arrangement was formed. Like ordinary crystals, photonic crystals are arranged with a band structure, there may photonic bandgap or photonic band gap between the photonic band. Photonic band gap, or band gap refers to a range of frequencies of electromagnetic waves in this frequency range can not propagate in the photonic crystal in the inside, and the frequency band is located in the electromagnetic wave is able to propagate almost lossless in the photonic crystal. Width and position of the band gap and the photonic crystal has a dielectric constant ratio relationship. WO3 can be continuously varied in a wide range of light irradiation or under the action of the electric field of the dielectric constant, and therefore with the tungsten oxide in the production of polystyrene template inverse opal photonic crystal structures can be more effective regulation of the optical path.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Cutting Fluid Lubrication Mechanism

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 March 2015 14:16

Tungsten carbide cutting tools in the cutting process, the lubricating oil is in common between the constantly moving constant friction surface, although the pressure is sometimes very large, very easy to form a lubricating film cutting fluid. Cutting fluid use state is different. Fresh surface formed by the time the cutting fluid remains in contact with the workpiece, and the machined surface has been in a state of elastic deformation, to be under great pressure between the tungsten carbide cutting tools and the workpiece surface to be processed, this pressure than the average Many great pressure to produce friction state.

After the metal-cutting machining using the cutting fluid, tungsten carbide cutting tools and the workpiece, the chip is formed between the lubricating film, the friction coefficient can be reduced, to reduce friction. Cutting the majority belong to the boundary friction friction. In machining, tungsten carbide cutting tools, workpiece and cutting fluids will be some elements from physical and chemical adsorption, chemical reactions, if they meet certain high-temperature, high-pressure conditions. Cutting fluid pumping action by immersing the contact surface tungsten carbide cutting stools and workpiece from the side, forming a lubricating film of low shear strength.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Application of High-density Tungsten Alloy in the Electrical Processing Industry

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 March 2015 09:00

Due to the high density tungsten alloy with good electrical properties and are widely used in the electrical processing industry

An electric riveting machine riveting head material

In electric riveting process, rivets temperatures up to 1000 ℃, but also to withstand the impact of the role of the arc ablation, high-density tungsten alloy of various metal rivets riveting has the following advantages:

1. The life of common materials than in the past rivet head up a few dozen to more than a hundred times;

2. Good quality, smooth and can not afford the rivet head pitting,

3. Convenient punch processing, high-speed steel to be heat treated alloy must EDM, high-density tungsten alloy can be used as long as the vehicle processing

High-density tungsten alloy is a class of tungsten-based (tungsten quality score is usually 80% to 97%), and added alloy Ni, Fe, Co, Cu, Mo, Cr and other elements, and its density as high as 16.5 to 19.0 g / cm3, and been known as high-density tungsten alloy, heavy alloy, heavy alloy. Not only high-density tungsten alloy density, but also has a series of excellent performance: high strength, high hardness, ductility, good machining properties, thermal expansion coefficient, thermal conductivity, anti-oxidation and good corrosion resistance, weldability good and so on. The excellent performance has been widely applied in the field of cutting-edge science, military, industrial and civilian industry. So far, W-Ni-Fe, W-Ni-Cu alloy has become a high-density tungsten alloy two major series.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Anviloy 1150 introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 March 2015 19:08

Anviloy 1150 is a machinable tungsten-based material that was developed primarily for die-casting, aluminum permanent mold, and difficult extrusions. To produce Anviloy 1150 material, we use special high temperature powder metallurgy processes. A low coefficient of thermal expansion, good thermal conductivity and good material properties at elevated temperatures combine for superior performance in a variety of applications. This unusual combination of properties results in less thermal fatigue and soldering in the die cast or extrusion.

Tungsten has a high melting point and low coefficient of thermal expansion. We add other elements to the tungsten to enhance machinability, ductility and strength, which makes it Anviloy 1150. Good thermal conductivity increases cooling in difficult to cool areas and can increase production rates. Material properties established during the production of Anviloy eliminate the problems often associated with heat treatment of other standard tool materials.

Specifications

Anviloy 1150

90%W + Ni Fe Mo

Application :Pressure die casting and hot extrusion dies

Excellent thermal conductivity

Material Components : W Ni Fe Mo alloy

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The advantage of Anviloy 1150

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 March 2015 19:06

Anviloy 1150 ( W-Ni-Fe-Mo ) is a tungsten based material made using special high temperature powder metallurgy techniques. Anviloy 1150 material has a low coefficient of thermal expansion, hot erosion resistance and good thermal conductivity.

The excellent thermal conductivity of Anviloy 1150 provides an additional benefit to increase cooling in difficult to cool areas. So, Anviloy 1150 can be used to increase cooling in critical areas to minimize porosity.

Anviloy 1150 ( W-Ni-Fe-Mo ) was developed primarily as an alternative to H-13 Tool Steels for die cast tooling to save you time and money. The advantage of Anviloy 1150 as the base for your dies, you will get more additional benefit as:

Longer die life

Better surface finishes on products

Fewer rejects

Lower cost

Less porosity in heavy sections

Application: Hot Extrusion Dies, Die Cast Tooling, and high mass and gyro.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Influence of Tungsten Oxide Film Thick

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 March 2015 17:12

Tungsten oxide films are of critical importance forelectrochromic device technology ,such as for smart windows capable of varying the throughput of visible light and solar energy.

Surface acoustic wave has been excited from a SAW device with 5.96 μm-thick ZnO and 1.15μm-thick UNCD films, which is successfully used for the streaming, pumping, and jetting of microdroplets of different sizes. The critical behaviors of different microfluidic phenomena were analyzed at different powers applied to the IDTs. The microfluidic efficiencies of the different ZnO-based SAW devices were investigated. Droplet pumping and jetting with different volumes were compared for the SAW devices with and without UNCD inter layers. Results show that the pumping velocities increase exponentially with the input power and those of the ZnO/UNCD devices are much larger than those of the ZnO/Si SAW devices at the same power. Based on the accurate analysis of the jetting dynamics, the maximum jetting angle is observed which depends on the droplet volume in the range 1.5–8μL during the jetting duration. The maximum jetting angle oscillates around 69° for droplets larger than 8μL.

Droplet streaming and nebulization on a 36oY-cut LiTaO3 SAW device have been realized using the SH-SAW. The streaming inside the droplet is sensitive to the position of the droplet, the coupling angle and droplet shape, which results in different flow patterns. Droplet nebulization was enhanced with the increased aperture size of the driven IDTs and mainly occurred in horizontal direction along two lateral sides of the droplet, which is perpendicular to the designed SAW propagation direction. The atomization duration increases with the droplet size, while it decreases with the driven power at a given drop size.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

ZnO Films and Tungsten Oxide Film

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 March 2015 17:05

Tungsten trioxide is used for many purposes in everyday life. It is frequently used in industry to manufacture tungstates for x-ray screen phosphors, for fireproofing fabrics and in gas sensors. Due to its rich yellow color, WO3 is also used as a pigment in ceramics and paints.In recent years, tungsten trioxide has been employed in the production of electrochromic windows, or smart windows. These windows are electrically switchable glass that change light transmission properties with an applied voltage.This allows the user to tint their windows, changing the amount of heat or light passing through.

The deposition process of ZnO/ultra-nanocrystal diamond (UNCD) film is simplified using the high target ultilisation sputtering technology and hot-filament chemical vapor deposition technique, which allow the growth of the high-quality multi-layer films with strong (0002) texture and fine grains. The ZnO/UNCD films have been successfully applied to fabricate SAW devices and the transmission signal obtained for the Rayleigh mode SAW is better than those using the conventional magnetron sputtering technique. The phase velocities show a significant thickness effect. The temperature coefficients of the frequency (TCF) for the SAW devices have been measured and a value of less than -30ppm/oC for the TCF could be obtained when the thickness of the UNCD layer ranges from 1.14 to 1.79 μm. For the SAW device with ZnO thickness of 7.68 μm and UNCD thickness of 1.06 mm, SAW achieves a coupling coefficient of 5.2%.The low TCF of -23.4 ppm/oC was obtained for the SAW devices with the 2.72μm-thick ZnO and 1.1 μm-thick UNCD film.

Love mode surface acoustic wave ultraviolet sensors have been fabricated using sputtered ZnO films on 36 Y-cut LiTaO3 substrate. Results from the UV sensing measurements show that the amplitude response of the Love mode SAW UV sensor operated at 41.5 MHz changed up to 6.4 dB and the fre-quency shift approached 150kHz under a 254 nm illumination at the power density of 350 μW/cm2. Whereas under a 365 nm illumination at a power density of 570 μW/cm2 the amplitude of thetransmission signal decreased only 2.5dB with no significant frequency shift. The frequency hopping effect during the downshift and recovery periods was identified due to the simultaneous interplays between the variations of the acoustic velocity andattenuation during the acoustic-electric interaction.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

EDM Parameters of Silver Tungsten Alloy(b)

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 March 2015 16:53

After the selection process is regulated quasi-polar and other process parameters, most of the artifacts are generally divided into coarse, medium, fine in order to convert several gage, both to ensure the technical requirements of the workpiece, but also to ensure the highest possible overall production efficiency. Select electric gage order should be determined according to the principal contradiction. Such as processing cavity mold, electrode wear ratio must be less than 1 percent, according to the requirements of the electrode should be selected loss ratio and peak current pulse width for roughing, then the production efficiency, rough degree in secondary position considered.

Such as precision machining small module gear die, in addition to side rough-givers, the main consideration should be to select the appropriate discharge gap, to ensure that they meet the requirements of the die gap.

Select the pulse interval of time, when roughing take long pulse width of 1 / 5-1 / 10, finishing 2-5 times to take the pulse width, pulse between the large, low productivity, but the width is too small, the processing unstable, arcing.

Processing area hours should not choose too large peak current, otherwise within the electrode gap is too thick causing galvanic corrosion product discharge centralized, easy arcing. Therefore, in the beginning may be rough few actual processing area should be temporarily reduce or increase the peak current pulse interval, or deliberately timed to strengthen carrying knives, electric fire until after the discharge area increases, the current increases to normal value. With increasing depth of processing should also be strengthened accordingly carrying knives and punch, pumping chip functions.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Nanocrystals Synthesized

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 March 2015 16:52

Tungsten oxide, also known as tungsten trioxide or tungstic anhydride, WO3, is a chemical compound containing oxygen and the transition metal tungsten. It is obtained as an intermediate in the recovery of tungsten from its minerals.Tungsten ores are treated with alkalis to produce WO3. Further reaction with carbon or hydrogen gas reduces tungsten trioxide to the pure metal.

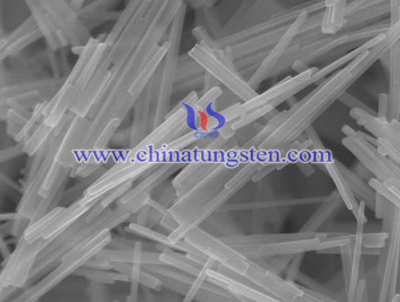

Tungsten oxide (hydrate) nanocrystals have been synthesized via hydrothermal route assisted by ammonium benzoate (AB), which showed the products with various morphologies, including the flower-shape, spherical and star-shape. Based on the analysis of the Fourier transform infrared spectra and observations of the time-dependent growth, a new self-assembly growth mechanism has been proposed for the formation of the different microstructures. The star-netted WO3 nanocrystals were applied as a sensitive layer for the relative humidity performed using a ZnO/LiTaO3.Love mode SAW device. The frequency shift has been observed with a sensitive response to the change of the relative humidity from 30% to 90%, and the frequency shift is linearly related to the relative humidity.

A new one-step method using the special holder has been developed to sputter-deposit the ZnO films. The typical columnar structure is inclined and the column inclination angle has been changed from 0o to 34o. X-ray diffraction analysis shows that the strains in the ZnO films decreased with substrate tilt angle. The optical characterization indicates tha the band-gap energies decreased from 3.19 eV to 3.07 eV, which has a linear relation to the strain in the ZnO films.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com