Tungsten Carbide Cutting Tool Wear

- Details

- Category: Tungsten Information

- Published on Friday, 06 March 2015 09:20

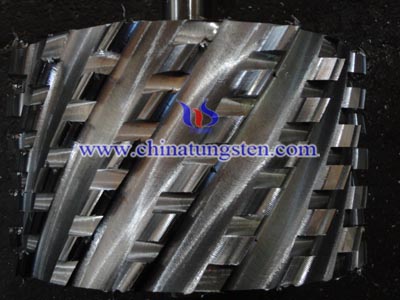

Tungsten carbide cutting tool wide range of applications, both for machining cast iron, non-ferrous metal and non-metallic materials, also suitable for processing a variety of steel and heat-resistant alloys. Both used in the manufacture of tungsten carbide indexable cutter machine folder and welding tools, can also be manufactured in various sizes smaller overall complex tools, such as the overall end mills, reamers, drills, composite processing tool and hobbing knives. At present, with the development of ultra-fine grain tungsten carbide technology, application of tungsten carbide cutting tools is still expanding.

When using cemented tungsten carbide cutting tool machining a variety of workpiece materials, high temperatures can cause cutting tool and the surrounding medium the oxidation reaction, the oxidation wear is easy to form the tool. Metal cutting tools in the process of forming the cutting edge portion has been cut metal adhesion transfer constituted "BUE" BUE was peeling from the cutter blade portion along with tool wear; Tool diffusion also occurs in the cutting process wear is worn between the relative wear caused by surface diffusion of elements; generated during cutting phase at high temperature in different metals, and the emergence of thermal current, which occurred in the electrochemical wear.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com