Tungsten Oxide Nanorods

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 17:14

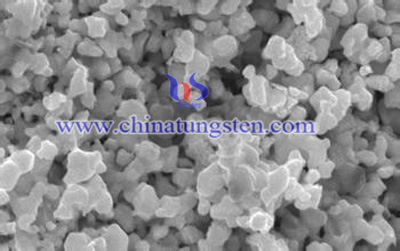

Tungsten oxides nanostructures have exhibited application perspectives in such fields as electrochromic (EC) device, photocatalysis, gas sensing, adsorption of organic dyes, etc. So far, in most high-temperature-reaction fabrications of the tungsten oxide nanostructures, the reactant sources and the substrates are separated. Occasionally, tungsten oxide nanostructures are grown directly from the metallic tungsten, which serves as both the reactant source and the substrate. Liu et al. obtained tungsten trioxide (WO3) nanowires by heating a thin W filament in vacuum with some air leakage. Quan et al. developed a single-step route for the direct growth of monoclinic WO3 nanobelt arrays by heating a W sheet without additional catalysts or reactants. The advantages of this direct heating method include short fabrication time, convenient manipulation, less expensive instrumentation and easy accession to high reaction temperatures. Most importantly, tungsten oxide nanostructures can grow directly from, instead of depositing on, the substrates. Therefore, a number of desired properties, such as good adhesion and low contact interface resistance, can be expected.

As previously reported, in this laboratory a fast heating chemical vapor deposition (CVD) system was developed, in which the temperature of the carbon substrate could be raised to 1800°C in 15 seconds with the passage of large electric current. Combined structures of conical carbon fiber and carbon nanotube (CCF/CNT), which had large length, good straightness and perfect crystallinity, were fabricated using this system. Recently, tungsten oxide nanostructures were also attained with similar instrumentation. This paper describes the fabrication process, characterization and field emission properties of these tungsten oxide nanostructures. In terms of heating uniformity, a Wfilament is apparently more controllable than a W foil when used as the directly heated substrate. However, since some applications, e.g., field emission and dye adsorption, require relatively large-area arrays of tungsten oxide nanostructures, W foils were deliberately used in this work.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com