Tungsten Oxide Nanomaterials

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 March 2015 18:31

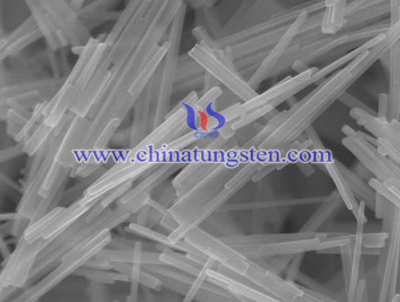

Nano-sized materials and products have been used widely in many applications because of their outstanding properties, different from those of the bulk materials. In early investigations into nanotechnology, the arc discharge technique was the first well-developed method used to manufacture nanoproducts, whose growth mechanism was, in particular, the effects of catalysts and the atmospheres on the products were considered to be very important. However, owing to difficulties involved in controlling the manufacturing parameters, the purity and quality of nanoproductssynthesized by arc discharge called for improvement. The inert gas condensation (IGC) system was thus established. Because there are no catalysts or containments, it is considered the cleanest method of producing high-quality products. In this system,metals are first placed in a tungsten or graphite boat and evaporated. The metal vapor is then cooled under an inert gas atmosphereto condense into clusters or nanoparticles.

Although the arc method has a higher production rate than IGC system, the latter produces larger particles. Hence, a modified technique based on the IGC system was developed, in which blowing gases were introduced to obtain finer particles with better particle size distribution.Several evaporation techniques are available, including electrical heating, laser vaporization, arc discharge and plasma arc. For some refractory materials, plasma arc is a promising method owing to its relatively high energy as compared to other heating methods. The use of a nozzle made the plasma arc induced by a modified torch more constricted and concentrated than that induced by a conventional torch. The conventional and modified plasma arc torches. To retain the benefits of both thearc discharge method and the IGC system, a plasma arc is used as the heat source and blowing gas is applied to quench the evaporated materials in this modified system. A simplified manufacturing process that enhances the purity of the as-prepared products is required. Therefore, an effective method, namely, the modified plasma arc gas condensation technique has been proposed.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com