Single-layer Tungsten Disulfide Mass Production

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 October 2018 22:56

Graphene is known as the king of materials, but graphene is a zero band gap two-dimensional material, can not be used as transistor channel layer, limiting its further application in nano-electronic devices, photoelectric conversion and other aspects.

Tungsten Carbide Silver Contacts Prepared By High-energy Ball Milling

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 October 2018 22:39

Electrical contacts are the core components of electrical switches, which play the roles of switching on, carrying and sectional current. Their performance largely determines the performance and reliability of electrical switches. Because of the high melting point of tungsten carbide and its strong resistance to electric corrosion, silver carbide has excellent conductivity and thermal conductivity, silver tungsten carbide materials also have good performance.

Chemical Coating Method for Silver Tungsten Carbide Contact Material

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 October 2018 22:28

Silver tungsten carbide contact material has the advantages of high hardness, oxidation resistance and relatively stable contact resistance compared with silver-tungsten contact material under the same manufacturing process, especially high breaking ability, low corrosion and low welding tendency. Silver tungsten carbide 40 contact material is usually used as contact material in modern circuit breakers abroad. Because of its superior performance, there has been a trend to replace silver tungsten 50.

Improved Extraction Method

- Details

- Category: Tungsten Information

- Published on Thursday, 11 October 2018 23:40

For the separation and extraction of tungsten, the common methods include solvent extraction, precipitation, ion exchange, activated carbon adsorption and so on. Overall evaluation shows that in the existing technology of separation of tungsten, there are many shortcomings, such as low separation efficiency, complex process, environmental pollution and so on. How to break through the existing technology and improve separation efficiency is the problem that scientific and technological personnel need to solve.

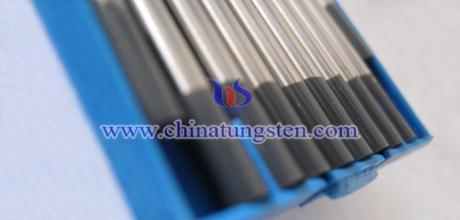

High Density Rare Earth Tungsten Electrode Manufacturing

- Details

- Category: Tungsten Information

- Published on Thursday, 11 October 2018 23:31

As an indispensable functional material in machinery, shipbuilding, aerospace, construction, nuclear power, metallurgy and other industries, tungsten electrode materials are mainly used in inert gas shielded welding, plasma cutting, spraying and smelting technology. At the same time, another important application of tungsten electrode material is to act as a hot cathode electron emission source in welding process.

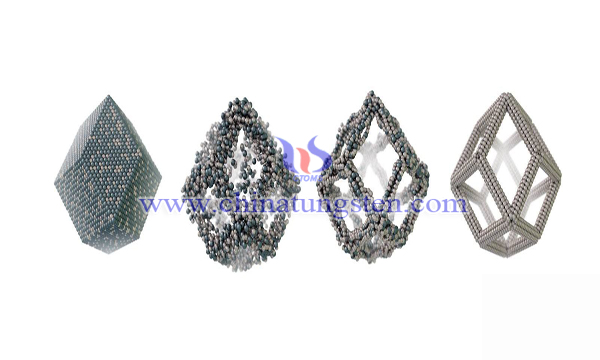

Spherical Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Thursday, 11 October 2018 10:10

Spherical tungsten powder has powder shape in spherical, compared to regular tungsten powder, it has the characteristics of good powder flowing ability and high tap density, it is widely used in thermal spray, multi porous material and powder metallurgy industry.

Nano Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Thursday, 11 October 2018 10:07

Nano tungsten powder is widely applied in aerospace alloy, electronic capsulation alloy, electrode material, micro electronic thin film, sintering aids, protective coating, gas sensing electrode. It is also applied for producing high property tungsten products and nano tungsten wire.

Ultra Coarse Tungsten Powder Preparation Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 October 2018 22:54

Tungsten powder can only be produced by powder metallurgy because of its high melting point, that is, tungsten powder can be obtained by reducing tungsten oxide or ammonium paratungstate (APT), and then tungsten and tungsten alloy products can be made. Due to the nature of tungsten itself, the particle size range of tungsten powder obtained by reducing tungsten oxide or ammonium paratungstate is generally 2-5 micron, so it is difficult to obtain ultra coarse tungsten powder.

Cyclic Ammonium Paratungstate Preparing Process

- Details

- Category: Tungsten Information

- Published on Monday, 08 October 2018 21:26

The preparation of ammonium paratungstate from sodium tungstate solution in tungsten metallurgical process mainly involves two steps: the preparation of pure ammonium tungstate solution and the crystallization of ammonium paratungstate. At present, when ammonium paratungstate is prepared by the above method, it is necessary to convert alkali into NaCl or Na2SO4 salt in the production system, which is difficult to recycle economically, resulting in serious environmental problems caused by emissions.

Tungsten Carbide Montmorillonite Composite Catalyst and Its Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 08 October 2018 21:12

Tungsten carbide (WC) is a kind of functional material with high hardness, good conductivity and high acid resistance. Since the discovery of platinum-like catalytic properties in the 1970s, WC has been widely used in catalytic hydrogenation, dehydrogenation, isomerization, hydrocarbon conversion and synthesis reactions in the chemical field. In the electrochemical field, WC also has a certain application prospect for hydrogen ionization and hydrogen evolution reactions.

sales@chinatungsten.com

sales@chinatungsten.com