Tungsen Trioxide Electrochromic Nanofilm

- Details

- Category: Tungsten Information

- Published on Monday, 23 July 2018 18:43

Electrochromism refers to the phenomenon that displayed by some materials of reversibly changing color under the action of an applied electric field. Electrochromic device only needs a small voltage (about 2V) to work, and the original color or fading state can be maintained in the open circuit, so the energy consumption is less.

Electrochromic devices are expected to be used in energy-efficient windows, anti-glare rearview mirrors, display devices, variable transmittance glasses, car sunroofs, and surface temperature control of spacecraft. Electrochromic materials are mainly divided into three types, namely inorganic electrochromic materials (generally transition metal oxides), organic single-molecule color-changing materials (such as Prussian blue, viologen, metal phthalocyanines, etc.) and conductive polymers. Materials (such as polyaniline, polypyrrole, polythiophene, etc.).

As an inorganic electrochromic material, tungsten trioxide (WO3) has the advantages of pure color, stable chemical properties and strong adhesion to the substrate. However, conventional tungsten trioxide also has the disadvantages of slow color change, low coloring efficiency, single color change, and short cycle life. In contrast, the nanostructured film has the advantages of large specific surface area, good electrical conductivity, rapid discoloration, good optical simulation performance, high coloring efficiency, and good cycle performance.

The most commonly used preparation methods for tungsten trioxide thin films are electrochemical deposition, hydrothermal, magnetron sputtering, and thermal evaporation deposition. There are some defects in these methods. For example, the prepared film is amorphous, the coloring speed is fast, but the cycle performance is poor or the prepared film is crystalline, and the cycle performance is good, but the color change speed is slow and the coloring efficiency is low.

At present, the core structure of tungsten trioxide core-shell composites mainly involves the design of core-shell structures such as tungsten trioxide and titanium dioxide, and zinc oxide nanorods. The core-shell structure of the homogenized material of the tungsten trioxide nanowire as the skeleton can take advantage of the crystalline-amorphous state of the tungsten trioxide itself, and improve the cycle performance through structural features.

A method for preparing an amorphous-crystalline tungsten trioxide core-shell electrochromic film comprises the following steps:

1) Dissolving leuco-tungstic acid in aqueous hydrogen peroxide solution, adding water to prepare a tungsten tungstate solution containing tungsten concentration of 1 to 5 mol/L, and coating the tungsten tungstate acid solution on the conductive surface of the conductive substrate to obtain coverage a conductive substrate of the seed layer;

2) Dissolving the tungsten source in water, adjusting the pH to 1 ~ 3.5, adding ammonium sulfate to form a precursor solution, fixing the conductive substrate covered with the seed layer to the reaction vessel, and adding the precursor solution to the reaction vessel. After reacting at 150 ° C to 250 ° C for 4 h to 10 h, the tungsten trioxide nanowire array film is obtained after removal;

3) Dissolve the tungsten source in water, add hydrogen peroxide, adjust the pH to 0.5~3, form an electrodeposition solution, and perform electrodeposition amorphous state on the tungsten trioxide nanowire array thin film electrode prepared in step 2) by constant voltage method. Tungsten oxide, an amorphous/crystalline tungsten trioxide core-shell electrochromic film is obtained.

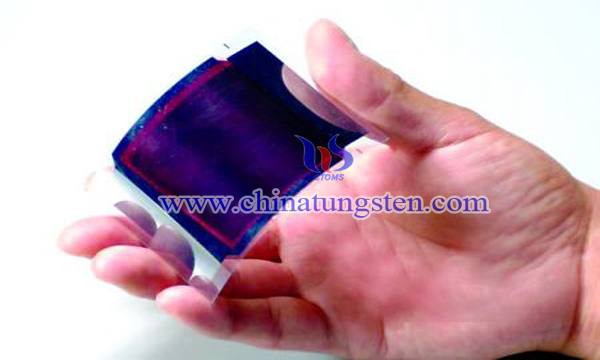

Preparation of tungsten trioxide electrochromic discoloration with nanowire array morphology on various substrates (such as ITO conductive glass, ITO/PET flexible conductive substrate, and glass and metal) by a combination of hydrothermal and electrodeposition methods. The film is then electrodeposited to form an amorphous tungsten oxide on the surface of the tungsten oxide nanowire to form a self-amorphous coating. Moreover, the preparation process is simple, and the nano-array structure morphology of the thin film can be conveniently controlled, the manufacturing cost is low, and large-area growth is feasible.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com