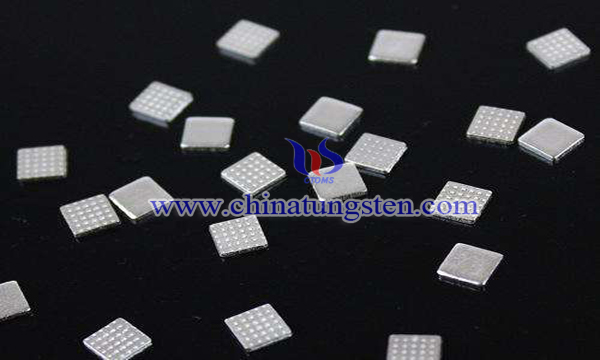

Silver-Nickel-Tungsten Contact

- Details

- Category: Tungsten Information

- Published on Friday, 20 July 2018 16:19

Silver-nickel contacts are widely used in various low-voltage electrical appliances due to their good thermal conductivity, low and stable contact resistance, and excellent processing properties. However, due to the weak anti-welding performance, the applications of silver-nickel contacts are limited.

It has been found that the addition of an appropriate amount of tungsten to the silver-nickel electrical contacts can greatly improve its resistance to fusion welding and expand the applications of silver-nickel contacts. At present, there are two main methods for preparing adding elements in silver-nickel contacts: powder metallurgy and chemical coating. In the two preparation processes, it is necessary to use toxic substances that are harmful to the human body and the environment. And the production cost is high, which is not suitable for industrial production.

In order to solve the existing process problems, some scholars have proposed a process for preparing a silver-nickel-tungsten contact material with simple process and uniform distribution of additives in the base material, which is characterized by the following steps:

1) Calculate the required amount of tungsten trioxide powder, nickel powder and silver nitrate according to the material ratio of the silver-nickel-tungsten contacts, and calculate the reaction between silver nitrate and sodium hydroxide according to the amount of silver nitrate. The amount of sodium hydroxide required for silver is weighed out; then, the silver nitrate solution is dissolved in water to prepare a silver nitrate solution of 20-40 w/%, and the tungsten trioxide powder and the silver nitrate solution are placed in the reactor, and the mixture is uniformly stirred. Obtaining a suspension containing silver nitrate and tungsten trioxide;

2) Dissolve sodium hydroxide solution in water to prepare 10~30w/% sodium hydroxide solution, add to the suspension obtained in step 1, stir the reaction, precipitate is formed. Filter it to obtain the composite powder of silver oxide and tungsten trioxide;

3) The obtained composite powder of silver oxide and tungsten trioxide is washed with water to neutrality, it is then dried, pulverized, calcined, and then pulverized again to obtain a silver tungsten oxide composite powder;

4) Mixing the obtained silver tungsten oxide composite powder with nickel powder to obtain a silver-nickel tungsten oxide mixed powder;

5) The obtained silver-nickel tungsten oxide mixed powder is oil-formed, and then placed in a reducing atmosphere for reduction to obtain a silver-nickel-tungsten compacts;

6) The obtained silver-nickel-tungsten compacts are subjected to pulverized, calcined again to obtain a silver-nickel-tungsten electrical contact material.

The composite powder of silver oxide and tungsten trioxide is obtained by reacting sodium hydroxide with a suspension of silver nitrate containing tungsten trioxide powder. The density of the tungsten trioxide powder (7.16 g/cm3) and the silver oxide formed by the reaction (7.143 g/ The density of cm3) is close to each other, so that the tungsten trioxide powder and the silver oxide can be more uniformly mixed, so that the tungsten trioxide powder is more uniformly distributed in the silver oxide matrix, which effectively improves the uneven distribution of the added elements in the prior art. On the other hand, the obtained silver-nickel tungsten oxide compact further refines the tungsten particles in the process of being reduced to the silver-nickel-tungsten compact, so that the distribution of the tungsten element in the matrix is more uniform and dispersed, thereby resulting in The silver-nickel-tungsten contact material has a uniform metallographic structure, and thus has excellent electrical properties, a simple process, and less harm to the human body and the environment, and is suitable for industrial production.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com