Nanometer Tungsten Trioxide Film

- Details

- Category: Tungsten Information

- Published on Friday, 20 July 2018 18:03

The solar photoelectrochemical (PEC) cell for hydrogen production is a technique based on solar energy and water. The products are hydrogen and oxygen. Both products are renewable. Thus, this technique has no harm to the environment, and can be applied on a small-scale production and mass production. Therefore, this technology is the most attractive hydrogen production direct use the solar energy

The performance of the semiconductor material that makes up the photoelectrode determines the efficiency of the PEC cell. Since semiconductor materials have a certain selectivity to sunlight and corrosion at the interface with liquids, which reduces the performance of semiconductors. So, focus of this study is to develop semiconductor materials with low band gap and high corrosion resistance.

Compared with traditional semiconductor materials such as titanium dioxide and zinc oxide, tungsten trioxide has a narrow band gap (2.5 eV). It can absorbs the visible light with a wavelength greater than 500 nm in the solar spectrum. It is inexpensive and has a good chemical stability. In short, it is a good solar energy semiconductor material for it is non-toxic and does not cause photo-corrosion. The nanometer tungsten trioxide film which can be used for the solar PEC cell for hydrogen production, and the preparation method are as following:

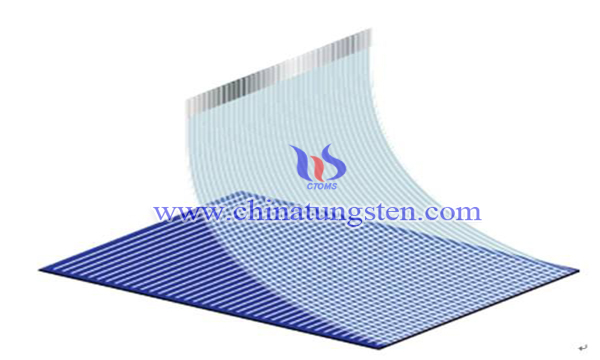

1. Preparation of precursor liquid: dissolve appropriate amount of water-soluble polytungstate in secondary deionized water, add a certain amount of dispersant and modifier, stir continuously with magnetic stirrer, and then stand at constant temperature to obtain precursor liquid. . The role of the dispersant is to form a large number of network-like interwoven structures, which are less prone to cracks during drying and high-temperature crystal formation; while the effect of the modifier enhances the stability of the precursor liquid, and in the process of film growth under high temperature conditions, it can be prevented. Nano-tungsten trioxide particles agglomerate, causing the film to fall off.

2. Coating method: coating on the substrate to be coated by dipping and pulling or spin coating, and drying under a certain temperature condition. The substrate to be coated should be pretreated by cleaning or the like. The base material is one of aluminum, stainless steel, glass, graphite, and silicon wafer.

3. Calcination method: After the base coating is dried, it is placed in a muffle furnace which can be programmed to control temperature and is calcined at a high temperature. The heating rate is 1-10 ° C / min, the baking temperature is 350-600 ° C, and the heat treatment is 2-5 h, thereby obtaining a nano tungsten trioxide film.

The nanometer tungsten trioxide film prepared by this process has good photoelectric performance: under a mercury lamp of 60 mW/cm 2 light intensity, a current density of 3.9 mA/cm 2 is obtained under a bias voltage of 1.5 V, and the photoelectric performance is a ratio of tungsten powder. The preparation of WO3 in the hydrogen peroxide process is 2-3 times higher.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com