The Unsung Heroes of Aerospace: High-Density Tungsten Alloy Counterweight Blocks

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 June 2025 11:32

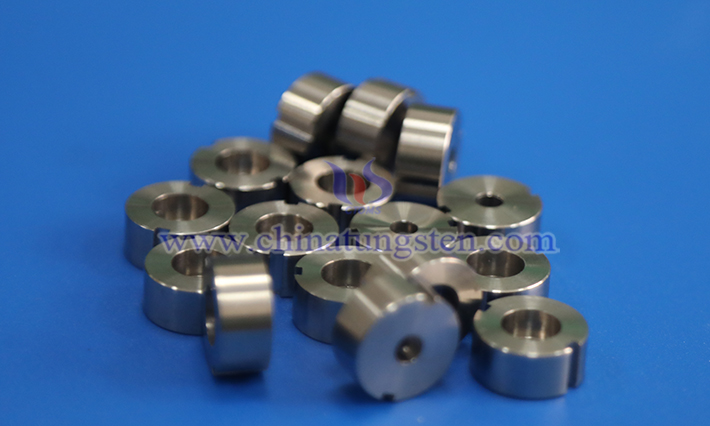

In the vast expanse of cosmic exploration and the graceful flight through blue skies, the aerospace industry demands materials with near-exacting performance standards. From the structural framework of aircraft to the intricate internal instruments, every component must exhibit high strength, low density, high-temperature resistance, and corrosion resistance to ensure safe and stable operation in extreme and hazardous environments. Among these critical materials, high-density tungsten alloy counterweight blocks stand out as unassuming yet indispensable heroes, playing an irreplaceable role in maintaining the balance and stability of flight vehicles.

I. Understanding High-Density Tungsten Alloy Counterweight Blocks

High-density tungsten alloy counterweight blocks are closely tied to the element tungsten, as their name suggests. Composed primarily of tungsten with the addition of elements like nickel, iron, and copper, this high-performance alloy material boasts exceptional properties. Tungsten’s inherent density of 19.3 g/cm³ imparts the alloy with an ultra-high density, typically ranging from 16.5 to 19.0 g/cm³, making it ideal for applications requiring dense materials.

Beyond density, these blocks offer remarkable strength and hardness, enabling them to withstand significant external forces and pressure without deforming or failing. Their excellent corrosion resistance is another highlight, allowing them to remain stable over long periods in the harsh environments of aerospace—such as high humidity, strong acids, alkalis, and extreme temperatures—ensuring reliability and longevity.

II. perse Transformations: Types and Manufacturing Processes

The family of high-density tungsten alloy counterweight blocks is perse, with common types including tungsten-nickel-iron and tungsten-nickel-copper alloys. Tungsten-nickel-iron alloys, based on a tungsten matrix with small amounts of nickel and iron, offer adjustable high density (around 18.8 g/cm³), strong high-energy ray absorption, low thermal expansion, good plasticity, and high strength and elastic modulus. These properties make them widely used in radiation protection, industrial counterweights, safety, and defense components.

Tungsten-nickel-copper alloys, also tungsten-based with added nickel and copper, stand out for their non-magnetic nature, making them valuable in radiation shielding applications sensitive to magnetic environments. In aerospace equipment with strict magnetic field requirements, these blocks prevent interference, ensuring precise operation.

The alloy’s exceptional performance and versatility stem from advanced manufacturing techniques. Injection molding is a key process, enabling the precise transformation of complex designs into small, high-precision, intricately structured tungsten alloy components. This allows for reduced volume at the same weight, facilitating compact aerospace designs. Powder metallurgy, another common method, involves mixing metal powders, pressing, and sintering them under controlled pressure and temperature to form shaped products with tailored composition and structure, yielding high-performance blocks.

III. Exploring Applications in Aerospace

1. The Precision “Balancer” in Aircraft

In the complex system of an aircraft, high-density tungsten alloy counterweight blocks act as skilled “balancers,” quietly performing critical roles in wings, tail assemblies, and engines. During flight, aircraft face complex external forces—airflow impacts, engine vibrations, and attitude changes—that threaten balance and stability. Counterweight blocks, through precise weight distribution, adjust the center of gravity to ensure balanced and stable flight.

In the wings, these blocks are typically installed at the leading or trailing edges. As wings generate lift, uneven lift distribution due to shape and airflow can cause twisting or vibration. Counterweights add weight to specific areas, altering the moment of inertia to reduce vibration and deformation, enhancing flight stability.

In aircraft engines, these blocks are equally vital. High-speed operation generates significant centrifugal forces and vibrations that, if unbalanced, can impair performance, lifespan, and safety. Installed in rotors, counterweights match weight and position to offset centrifugal forces, reducing vibration and noise while boosting reliability and stability.

2. The Reliable “Stabilizer” in Spacecraft

Shifting focus from the skies to the cosmos, high-density tungsten alloy counterweight blocks are essential “stabilizers” for spacecraft. They play unique roles across launch, orbital operations, and attitude adjustments.

During launch, these blocks adjust the spacecraft’s center of gravity to ensure stability under rocket thrust and complex aerodynamics. An unstable center of gravity could lead to rolling or deviation, but precise weight placement aligns it with thrust direction, ensuring a stable ascent along the intended trajectory.

In orbit, spacecraft must maintain precise positions and attitudes for scientific missions. Exposed to subtle forces like solar radiation pressure, Earth’s gravitational perturbations, and other celestial influences, their orbits and attitudes may drift. Counterweights, working with attitude control systems, generate small torques to counteract these forces, keeping the spacecraft on course.

For attitude adjustments—such as targeting celestial bodies or docking—counterweights assist by shifting positions or weight distribution to produce torques, enabling quick and accurate reorientation.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com