Tungsten and Molybdenum Separation by Ion Exchange

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 September 2018 22:14

Due to the similar properties of tungsten and molybdenum, separation of tungsten and molybdenum has always been a key and difficult problem in tungsten smelting industry. It is well known that the traditional ion exchange process is difficult to solve the problem of W-Mo separation at one time, resulting in a large number of supplementary materials, but also to bring a lot of environmental management difficulties to enterprises.

High Efficiency Tungsten Oxide / Copper Oxide Composite Gas Sensitive Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 September 2018 22:04

Metal oxide semiconductor gas sensor has the advantages of low cost, high sensitivity, easy control and operation. It is widely used as a functional device in gas sensing, photocatalysis, solar cells and so on. At present, tungsten oxide (WO3) is considered to be superior to ZnO, SnO2, and TiO2 in semiconductor metal oxide gas sensing materials for high efficiency detection of NOx.

Ammonium Paratungstate Crystallization Optimization Scheme

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 September 2018 21:54

Ammonium paratungstate (APT) is an important intermediate compound in the production of tungsten powder, tungsten wire, tungsten-based alloy and all tungsten materials. It is also a bulk export commodity in China. Due to genetic relationship, APT crystal characteristics such as crystal morphology, lattice parameters, average particle size and particle size distribution, bulk specific gravity and fluidity have great influence on the material properties of tungsten powder, tungsten wire and tungsten alloy.

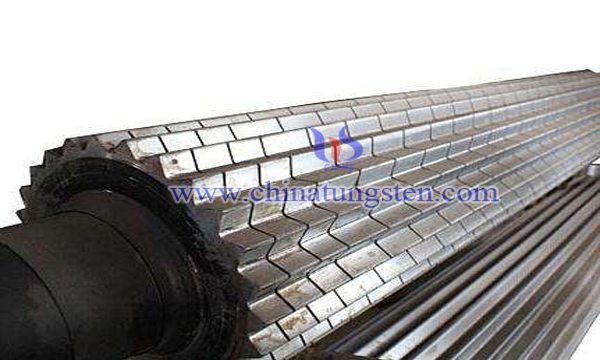

Corrugated Roll Tungsten Carbide Cobalt Coating Reinforcement

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 September 2018 23:51

Thermal spraying technology is a key technology in the field of surface modification. As a wear-resistant and corrosion-resistant coating, tungsten carbide/cobalt coating is widely used in aerospace, metallurgy, machinery and other fields because of its high hardness and good toughness. Compared with hard chromium plating, thermal sprayed WC-Co coating has obvious advantages in wear resistance, corrosion resistance, fatigue resistance and so on, and has the advantages of rapid preparation and less environmental pollution.

Tungsten Oxide Electrochromic Film

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 September 2018 17:49

A variety of color-changing films can be seen everywhere in life, and the materials for making color-changing films are very wide. One of the new materials is the tungsten oxide electrochromic film.

Researchers Have Developed A New Tungsten Oxide Nanofiber Membrane

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 September 2018 16:08

The life on earth is inseparable from the sun. With the development of science and technology, people realize that sunlight provides enough renewable green energy to achieve higher solar-thermal energy conversion efficiency and achieve more efficient water evaporation performance. The topic of photothermal materials----tungsten oxide nanofiber membranes is constantly being explored.

Advantages of Nano Tungsten Oxide Insulating Glass

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 September 2018 14:37

Nano tungsten oxide heat-insulating glass is one kind of coated glass, which is produced through mixing a mixture of 5-10nm nano tungsten oxide and indium-phosphide oxide with resin and diluent, and then coat on the glass surface. The new coated glass has the advantages of good heat insulation performance, high transparency and good anti-UV effect, and is widely used in architectural glass curtain wall, vehicle and ship glass and other industries.

Tungsten Oxide Insulating Glass Could Protect Children's Skin Health

- Details

- Category: Tungsten Information

- Published on Friday, 21 September 2018 20:52

Tungsten oxide insulating glass can effectively prevent ultraviolet rays come into the room, and protect people skin health, especially for infants’ and children’ skin health.

Tungsten Oxide Insulating Glass Makes Eco-friendly Society

- Details

- Category: Tungsten Information

- Published on Friday, 21 September 2018 19:36

Tungsten oxide insulating glass is a new type of eco-friendly building material. During the glass producing process, a proper proportion of rare metal oxide tungsten trioxide is added to make the glass have better thermal insulation performance, and barrier the ultraviolet rays and infrared ray from the sun. In Europe and America, it has become the industry standards to use the thermal insulating glass in the architecture project. The increasingly energy crisis has got the Chinese government attention, and the government cast the proposal to build eco-friendly society through using the eco-friendly and energy-saving materials in the different industries.

Mo Crucible and Assembling Mold

- Details

- Category: Tungsten Information

- Published on Monday, 17 September 2018 20:13

In order to save the cost, the production of Mo crucible mainly uses the assembling mold with the method of powder metallurgy.

The feature of Mo crucible is that the part is composed of wall cylinder and the hypo-cone.

The ratio of height to thickness of the wall cylinder is close to 8. It is easy to generate the cracks on the surface during the manual pressing. Therefore, we use the assembling molds and adopt the method of powder metallurgy to solve this problem. Due to the friction between powders and between powder and molds, the pressure loss occurs during the pressing. We adopt the double-direction pressing in order to increase the density of hypo-cone and ensure the uniformity of green compact density. After finishing the first pressing, the die cushion will be removed and the second pressing starts. In order to facilitate the demolding of the hypo-cone of the Mo crucible from the base, the base is composed of three vertically and equitably separated block (include the die block, the upper die punch and the wall cylinder of the Mo crucible).

The advantages of using the assembling molds are listed as below:

1.0 The use of assembling mold for pressing can help control the density of various parts of Mo crucible, and ensure that the density of parts of the parts are consistent.Therefore, it improves the performance of the process.

2.0 The adoption of double-direction pressing compensates for the low density caused by the pressure loss and increases the density of every part.

3.0 The base of assembling mold is composed of three parts which can solve the problem that the hypo-cone part is not easily demolded. The application of assembling mold is one of the effective ways to produce the Mo crucible. The promotion of this method can show the feature of powder metallurgy production and accelerate the development of powder metallurgy industry.

- TZM Manufacturer & Supplier, Chinatungsten Online: titanium-zirconium-molybdenum.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com