The Application of Nano Tungsten Oxide on Glass Curtain Wall

- Details

- Category: Tungsten Information

- Published on Friday, 28 September 2018 20:13

People's aesthetic requirements for modern architectural design are getting higher than before, and the nice combination of aesthetics and functions of the architecture owns to the emergence of glass curtain wall, and get the favor of architects. The glass curtain wall is simple, luxury, and modern, in addition, this architectural material can reflects the surrounding scenery very well which could show a good decorative effect. The glass curtain wall combining the exterior wall with the windows, which could reduce the weight of the building itself. And this kind of structures has the advantages of light weight, easy installation and the others during the process of construction.

Nano-tungsten Oxide Insulating Glass Blocks Solar Heat Radiation

- Details

- Category: Tungsten Information

- Published on Friday, 28 September 2018 19:49

As people know, many magnificent natural phenomena on the earth benefit from the distribution of solar energy on the surface of the earth, seasonal changes, climate differences, ocean currents, etc., almost all the earth's environment is inseparable from the influence of solar thermal radiation. At the same time, the energy of solar radiation is the source of power for the development of human society. From the ancient time, human beings keep their labor steps with the dawn and dark, in the modern civilization, people use solar power to generate electricity. The sun gives us almost everything we need. The whole world will become lifeless if the earth were without the sun.

The Application of Tungsten Oxide Thermal Insulation Coat on Old Architectural Glass

- Details

- Category: Tungsten Information

- Published on Friday, 28 September 2018 19:20

The success research and development of the tungsten oxide thermal insulation coating material solved the long-disturbing engineer’s construction problems for the old buildings’ insulation, in which way simplifies the construction difficulty and get the purpose of prolonging the use time of buildings. It is a new method that spray the tungsten oxide thermal insulation coat on the surface of old architectural glass to achieve a low-cost construction solution for the building insulation.

Winter Garden with Tungsten Oxide Heat insulating Glass

- Details

- Category: Tungsten Information

- Published on Thursday, 27 September 2018 21:11

The application of tungsten oxide heat-insulating glass on the winter garden could solve problem of the warm in summer and cool in winter that troubled the traditional winter garden, so as to reduce the energy consumption, such structure is called as tungsten oxide heat-insulating glass sun room by people.

Tungsten Oxide Insulating Glass Dome

- Details

- Category: Tungsten Information

- Published on Thursday, 27 September 2018 20:53

The tungsten oxide insulating glass dome is an architectural structure formed by installing a tempered glass with a tungsten oxide thermal insulation coat, and then fixed on the reinforced structure. Such structure is seen as an improvement of the traditional glass architectural structure.

Tungsten Oxide Insulating Glass Dome

- Details

- Category: Tungsten Information

- Published on Thursday, 27 September 2018 20:49

The tungsten oxide insulating glass dome is an architectural structure formed by installing a tempered glass with a tungsten oxide thermal insulation coat, and then fixed on the reinforced structure. Such structure is seen as an improvement of the traditional glass architectural structure.

Green Patron: Tungsten Oxide Heat-insulating Glass

- Details

- Category: Tungsten Information

- Published on Thursday, 27 September 2018 20:10

Because of the thin tungsten oxide coating, tungsten oxide heat-insulating glass could have good effect on blocking heat-insulating radiation, at the same time this material has high transparency. It is widely used in the construction of winter garden in the tropical botanical garden.

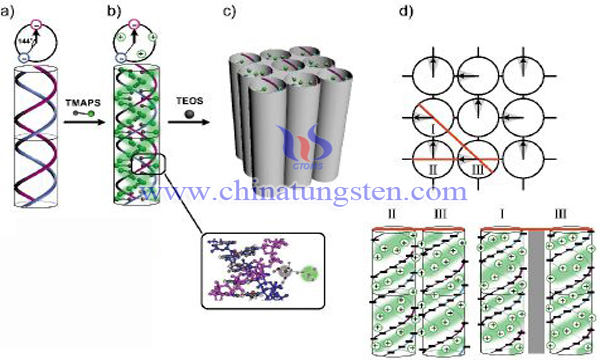

Mesoporous Tungsten Carbide Synthesis

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 September 2018 22:40

Because the surface electron layer of tungsten carbide (WC) is similar to platinum (Pt), it has a Pt-like catalytic activity in some reactions. In addition to the field of cemented carbide, the application of tungsten carbide as a non-noble metal catalytic material with excellent performance has attracted much attention.

Tungsten and Molybdenum Separation by Ion Exchange

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 September 2018 22:14

Due to the similar properties of tungsten and molybdenum, separation of tungsten and molybdenum has always been a key and difficult problem in tungsten smelting industry. It is well known that the traditional ion exchange process is difficult to solve the problem of W-Mo separation at one time, resulting in a large number of supplementary materials, but also to bring a lot of environmental management difficulties to enterprises.

High Efficiency Tungsten Oxide / Copper Oxide Composite Gas Sensitive Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 September 2018 22:04

Metal oxide semiconductor gas sensor has the advantages of low cost, high sensitivity, easy control and operation. It is widely used as a functional device in gas sensing, photocatalysis, solar cells and so on. At present, tungsten oxide (WO3) is considered to be superior to ZnO, SnO2, and TiO2 in semiconductor metal oxide gas sensing materials for high efficiency detection of NOx.

sales@chinatungsten.com

sales@chinatungsten.com