The Old Driver Tells You How Mysterious This Transparent Car Insulation Film Is

- Details

- Category: Tungsten Information

- Published on Friday, 02 November 2018 09:17

The old driver said that this transparent car insulation film, which you may not know, is a tungsten oxide transparent car insulation film. Although, at present, there are many kinds of car films on the market, such as 3M, Weigu, Ray-Ban, etc...

Calcium Tungstate Molybdenum Removal Optimization Process

- Details

- Category: Tungsten Information

- Published on Thursday, 01 November 2018 22:28

Tungsten and molybdenum are similar elements, and their physical and chemical properties are very similar. Tungsten minerals are all associated with molybdenum, but the content is different. With the depletion of high-grade tungsten resources, low-grade tungsten resources and secondary tungsten resources have become more and more important tungsten metallurgical raw materials. The molybdenum ion concentration in calcium tungstate solution produced from these raw materials is also increasing. In order to produce pure tungsten compounds, it is necessary to remove molybdenum completely and efficiently from calcium tungstate solution.

Nano Tungsten Oxide Aqueous Solution Preparation Method

- Details

- Category: Tungsten Information

- Published on Thursday, 01 November 2018 22:00

Tungsten oxide is a typical transition metal oxide, and nano-tungsten oxide is a new type of functional material. Due to its excellent discoloration performance, it is used in smart windows, large-area flat panel displays, gas sensors, dye-sensitized solar cells, and automatic There are a lot of potential applications in many new fields, such as rearview mirrors and energy storage devices.

Silicon Carbide/tungsten Carbide Composite Coating

- Details

- Category: Tungsten Information

- Published on Thursday, 01 November 2018 21:55

Wear has become one of the main reasons for the failure of modern industrial machinery parts. With the development of industry, more and more high wear-resistant materials are required, and wear-resistant coatings have become the standard of most important wear-prone materials.

Tungsten Oxide / Vanadium Oxide Heterojunction Nanosensitivity Materials

- Details

- Category: Tungsten Information

- Published on Thursday, 01 November 2018 21:46

Tunsten trioxide is a metal oxide semiconductor. It is a surface conductance (resistance) controlled gas sensitive material. The atomic properties of WO3 crystal surface are active and it is easy to adsorb gas molecules. When gas molecules adsorb on the crystal surface, the carrier concentration inside the WO3 crystal will change correspondingly, which shows the change of sensor resistance. Because the active atoms of tungsten oxide are located on the surface of the crystal, the contact area between the crystal surface and gas is greatly enlarged, which can effectively improve the gas sensing performance. It can be used in indoor environment detector, air purifier assembly, dangerous gas alarm device and so on.

High Intensity Magnetic Separation of Scheelite

- Details

- Category: Tungsten Information

- Published on Thursday, 01 November 2018 21:28

At present, the coarse separation of scheelite is usually by gravity separation or flotation. Because scheelite is a kind of ore which is easy to be gravity-dressed, but because scheelite has fine dissemination size, it needs to be grinded to 0.2 mm before the basic monomer dissociation, thus increasing the difficulty of gravity recovery, and the recovery rate of gravity-dressing is low, the taste of scheelite in crude concentrate is not high.

New Environmentally Friendly Rare Earth Pigments are In Line with International Standards

- Details

- Category: Tungsten Information

- Published on Thursday, 01 November 2018 09:29

Environmental issues have followed the rapid development of the social economy. Nowadays, environmental issues have been put on the agenda as an important issue that cannot be avoided. Therefore, we must not only pursue economic development, but also go side by side with environmental protection! Therefore, the emergence of new environmentally-friendly materials will always become a topic after people have a meal. Although it is only a topic of time, it is not very shocking and will not detonate the audience. It just makes people feel inexplicable peace of mind! For example, the emergence of new environmentally friendly inorganic pigments, rare earth pigments, is still the focus of attention in the near future, because our new environmentally friendly rare earth pigments have been in line with international standards! And environmental protection is the eternal trend!

2018 Summer Davos Forum: Blockchain Will Influence and Change the World

- Details

- Category: Tungsten Information

- Published on Wednesday, 31 October 2018 09:50

A few days ago, the 2018 Summer Davos Forum and the 12th Summer Davos Forum were held in Tianjin. The theme of this forum is “Building an innovative society in the fourth industrial revolution”. The theme of this conference is mainly aimed at the issues of general concern to all parties, namely, how to continue to strengthen new kinetic energy in the current international environment, where the factors of instability and uncertainties have increased significantly, and the trend of anti-globalization has risen. And promote the sustained and steady growth of the world economy?

Pulse Reverse Deposition of Thick Tungsten Coating

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 October 2018 22:40

Tungsten has a very high melting point, very high strength, very small electron overflow work, and good chemical and chemical properties such as good chemical stability and high temperature conductivity. Therefore, tungsten has excellent properties in the electronics industry and aerospace technology. Application prospects, molten salt electrodeposition is a method for preparing high-quality metals, with its simple equipment composition and operation methods, as well as its good bonding ability and other advantages have been widely concerned.

Silver Tungstate Composite Silver Phosphate Photocatalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 October 2018 22:32

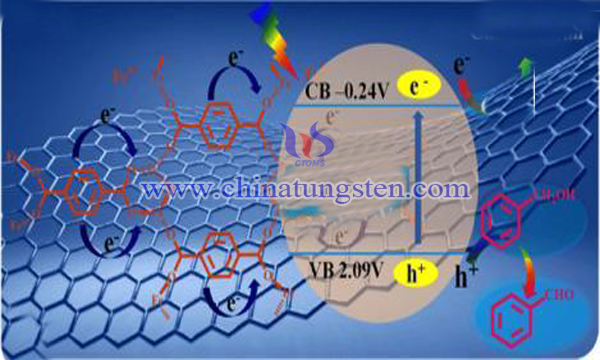

In the field of pollutant degradation and energy production, semiconductor photocatalysis is one of the most promising methods. In 2010, researchers at the Material Research Institute found that silver phosphate had photocatalytic effects, and the photocatalytic oxidation effect was more than tens of times that of the known photocatalysts.

sales@chinatungsten.com

sales@chinatungsten.com