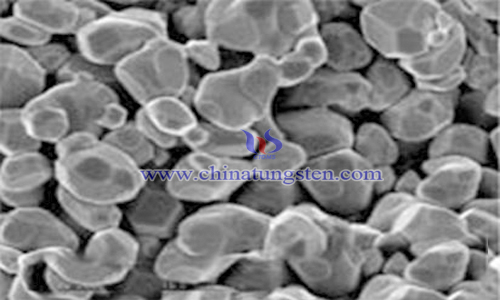

How to Activate Unbonded Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Friday, 23 November 2018 22:42

Tungsten carbide cemented carbide is widely used in cutting, drilling, mining, tool forming and wear-resistant parts because of its high hardness, high strength, high toughness, wear resistance, high temperature resistance and low expansion coefficient. Generally speaking, tungsten carbide alloys need cobalt and nickel as bonding phases. Although metal bonding phases promote sintering densification, they also reduce hardness, wear resistance, corrosion resistance, oxidation resistance and so on. At the same time, there are large differences in thermal expansion coefficients between metal phases and tungsten carbide and other hard phases, which lead to the material. Because of the large thermal stress, the application area is limited.

Tungsten Disulfide / Attapulgite Composite

- Details

- Category: Tungsten Information

- Published on Friday, 23 November 2018 22:37

Tungsten disulfide has attracted much attention for its excellent lubricity and catalytic performance. Although tungsten disulfide has excellent properties, its properties still need to be further improved in many cases. Compounds with other inorganic substances are one of the ways to improve its properties.

Tungsten Oxide Nanoparticle Gas Sensor

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 November 2018 22:59

Tungsten oxide is a kind of N-type semiconductor material with wide band gap. It is widely used in the field of gas sensors and can be widely used in the detection of various toxic and harmful gases. However, like most metal oxide semiconductors, tungsten oxide operates at a higher temperature (above 200 ℃), which greatly increases the power consumption of the sensor. Therefore, reducing the working temperature of tungsten oxide gas sensing materials has become the focus of scientific and technological personnel.

World Tungsten Capital, Asian Copper Capital, Jiangxi's Geological Exploration Economy Will Break 7.5 Billions

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 November 2018 09:17

Recently, the 60th Anniversary Symposium of Jiangxi Provincial Bureau of Geology and Mineral Resources was held in Nanchang. It was learned that the Jiangxi Bureau of Geology and Minerals has made new breakthroughs in geological prospecting since its establishment 60 years ago: it has discovered and discovered five world-class deposits, more than 60 large and extra-large deposits, and more than 90 medium-sized deposits. The economic value exceeds 10 trillion yuan, providing a strong mineral resource guarantee and geological technical support for the economic and social development of Jiangxi Province. With the continuous growth of Jiangxi's geological prospecting economy, this year is expected to exceed 7.5 billions.

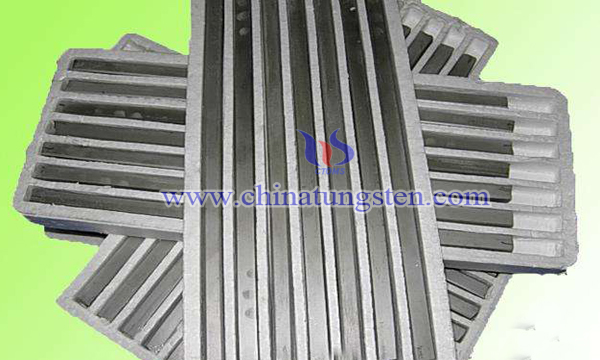

Gradient Porous Tungsten Manufacturing Process

- Details

- Category: Tungsten Information

- Published on Monday, 19 November 2018 22:52

Porous tungsten is widely used in power electronics, aerospace and other high temperature fields as a variety of components prepared by porous or porous matrix, such as porous cathode matrix with high current density, high temperature fluid filter, high temperature heater of rocket nozzle, etc.

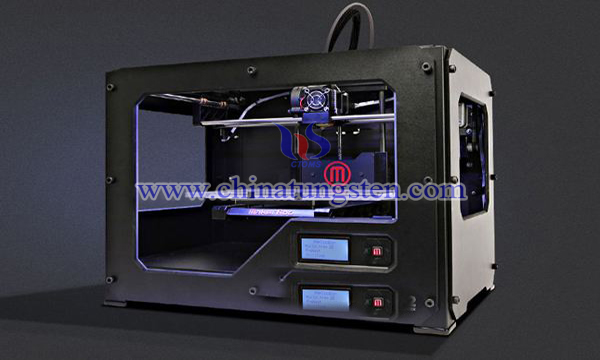

Pure Tungsten 3D Printing Additive Manufacturing Exploration

- Details

- Category: Tungsten Information

- Published on Monday, 19 November 2018 22:44

Additional material manufacturing is a new processing technology, commonly known as 3D printing, which is different from the traditional "removal" manufacturing. It does not need the original embryo and die. It directly forms any complex shape object by adding material layer by layer according to the computer three-dimensional model data of parts.

Secondary Sintering Process of Potassium-containing Metal Tungsten Bars

- Details

- Category: Tungsten Information

- Published on Monday, 19 November 2018 22:34

Potassium-containing tungsten bars are raw materials for making light source materials, high-temperature heaters and high-temperature resistant components. The traditional production method is to add silicon, aluminium, potassium and other elements into tungsten oxide powder first, then reduce the tungsten oxide powder doped with these elements and wash it with hydrochloric acid and hydrofluoric acid to obtain doped tungsten powder, then doped tungsten powder. After being pressed, the strips are sintered and sintered to obtain potassium containing tungsten bars.

Tungstate / Tungsten Oxide Heterojunction Photocatalyst

- Details

- Category: Tungsten Information

- Published on Monday, 19 November 2018 22:26

Tungsten trioxide (WO3) is a typical n-type semiconductor material, which has broad application prospects in electrochromic devices, gas sensors and photocatalysts. Particularly in the field of photocatalysis, WO3 has a narrow band gap (2.4-2.8eV) compared with other semiconductors (such as titanium dioxide and Bi2O3), which can utilize solar energy more effectively.

Low Grade Scheelite Tailings Recovery Method

- Details

- Category: Tungsten Information

- Published on Monday, 19 November 2018 22:18

China is a large producer of tungsten, and its reserves and output rank first in the world, but this is not worth showing off. Due to historical reasons and technical limitations, the development of tungsten resources in the early and middle stages of China has not been carried out reasonably.

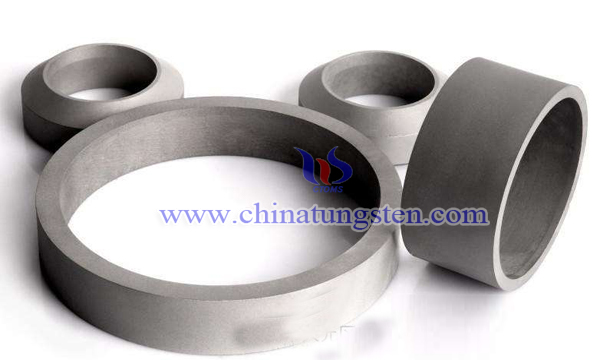

Tungsten Carbide Ceramic Heat-resistant and Wear-resistant Composites Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 19 November 2018 22:07

Tungsten carbide ceramics are widely used in metal processing, mining and other fields because of their high hardness, wear resistance, heat resistance, corrosion resistance and other excellent properties. However, tungsten carbide ceramics have high manufacturing cost and brittleness, and are not suitable for wearable parts with high impact force.

sales@chinatungsten.com

sales@chinatungsten.com