U.S. Retreats "Zhongdao Treaty", Real Intention Maybe Is to Limit China's Medium-range Missiles

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 November 2018 10:17

Since Trump announced on the 20th of this month that the United States will withdraw from the "Medium Guide Treaty" signed by Russia, foreign diplomatic agencies and the media have taken action to try to figure out what the real intention behind the "retrefation" of the United States is. Although Trump claims that the United States would want to withdraw from the landmark "middle-range nuclear power treaty" because of Russia's long-standing violation of the treaty. In this regard, the Russian side insisted that the US accusation has no evidence, and it also refers to the US party's breach of contract. In addition, some Russian media analysts believe that the US is determined to withdraw, and the real intention is to limit China's medium-range missiles.

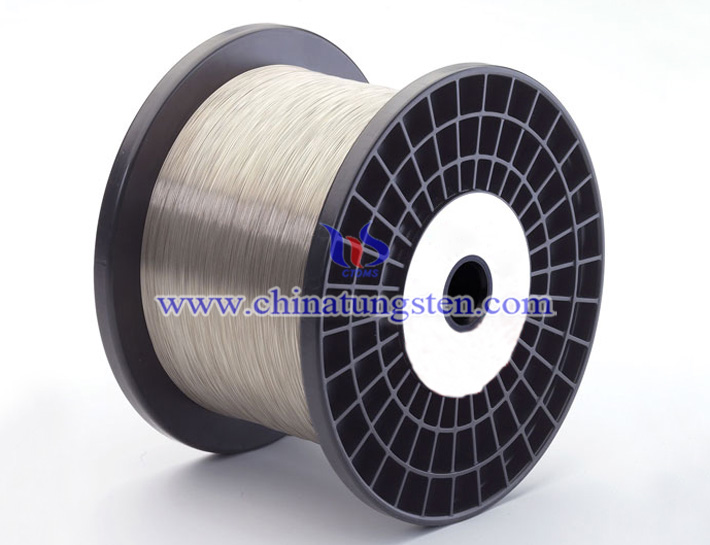

Molybdenum Bismuth Alloy Wire is A Mainstream Wire for Wire Cutting

- Details

- Category: Tungsten Information

- Published on Tuesday, 13 November 2018 09:05

Is the bismuth molybdenum bismuth alloy wire the main wire cutting electrode wire? A group of research materials will tell you later. We start with the “six hopes” of the wire cutting industry. There are so many expectations in the wire-cutting boss: one is looking forward to the wind; the second is not changing the liquid; the three expecting the meter does not turn; the fourth is expecting the rent to be halved; the five hope that the sun does not fall; the six-hundred machine turns over 10,000! However, the wire-cutting master and the little master said after hearing that they did not say the "five expectations" in the back. We first realized the "first hope", that is, when the "electrode wire is not easily broken", other.

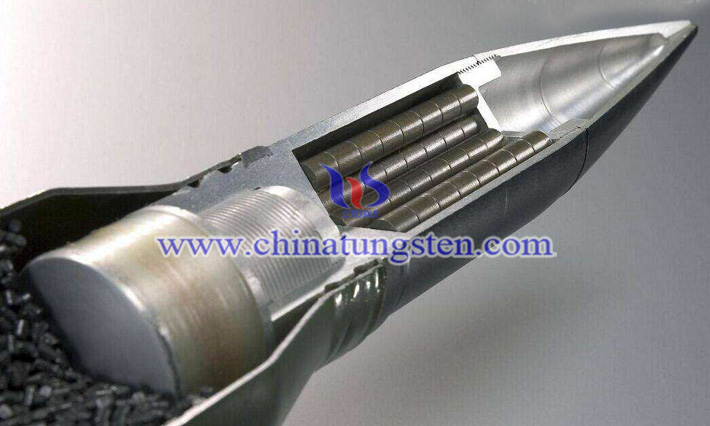

China's Large-Scale Radial Precision Forging Machine Technology Has Made A Breakthrough, The Power Of 99 Tank Guns Will Be Greatly Improved

- Details

- Category: Tungsten Information

- Published on Monday, 12 November 2018 09:56

Recently, China's newly developed TMH20/15MN large radial precision forging machine was successfully tested at one heat load, and the first qualified high-end bar was forged. The successful test of the radial precision forging machine marks that the core manufacturing equipment of high-end pipe in China will no longer be easily "card neck"! However, this also means that China has successfully broken one of the technical barriers that have long been completely monopolized by foreign countries - large radial precision forging machine preparation technology!

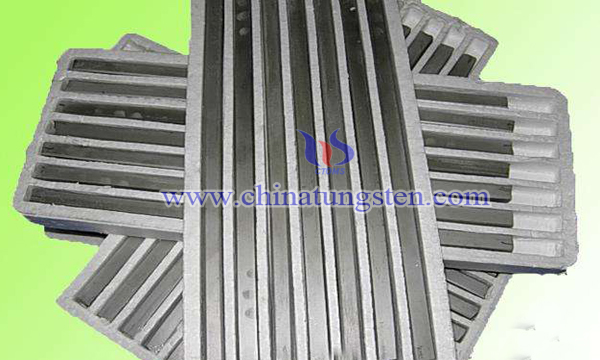

Secondary Sintering Process of Potassium Containing Metal Tungsten Bars

- Details

- Category: Tungsten Information

- Published on Monday, 12 November 2018 00:19

potassium containing tungsten bars are raw materials for making light source materials, high-temperature heaters and high-temperature resistant components. The traditional production method is to add silicon, aluminium, potassium and other elements into tungsten oxide powder first, then reduce the tungsten oxide powder doped with these elements and wash it with hydrochloric acid and hydrofluoric acid to obtain doped tungsten powder, then doped tungsten powder. After being pressed, the strips are sintered and sintered to obtain potassium containing tungsten bars.

Tungstate / Tungsten Oxide Heterojunction Photocatalyst

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 23:57

Tungsten trioxide (WO3) is a typical n-type semiconductor material, which has broad application prospects in electrochromic devices, gas sensors and photocatalysts. Particularly in the field of photocatalysis, WO3 has a narrow band gap (2.4-2.8eV) compared with other semiconductors (such as titanium dioxide and Bi2O3), which can utilize solar energy more effectively.

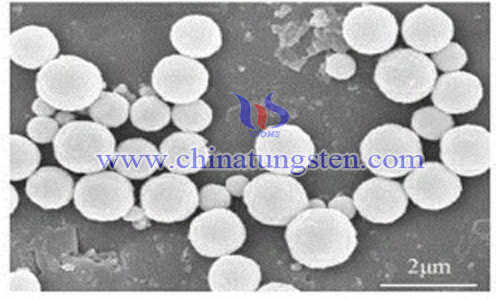

Nano Tungsten Probe Preparation Method

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 23:36

Scanning Tunneling Microscope (STM) is an instrument for detecting various surface information with atomic spatial resolution. The structure of the probe tip is one of the main factors determining the performance of the instrument. For example, the size, shape and chemical purity of the tip will affect the electron density of states of the atoms on the surface of the material under test, and the image of the STM. It has important influence on the resolution and quality.

Three-dimensional Graphene Encapsulated Cesium Phosphotungstate Microspheres Preparation Method

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 23:29

Heteropoly acids, also known as polymetallic oxygen clusters, are metal-oxygen clusters formed by bridging metal atoms with oxygen atoms. The so-called Keggin-type heteropoly acid has the reversible redox property of multi-electrons. Therefore, the active capacity of the composite material used as the cathode of lithium-ion batteries reaches 260 Ah/kg, which is much higher than that of ordinary lithium-ion batteries.

Tungsten Carbide Ceramic Heat-resistant and Wear-resistant Composites Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 23:13

Tungsten carbide ceramics are widely used in metal processing, mining and other fields because of their high hardness, wear resistance, heat resistance, corrosion resistance and other excellent properties. However, tungsten carbide ceramics have high manufacturing cost and brittleness, and are not suitable for wearable parts with high impact force.

Tungsten-doped Vanadium Dioxide Film Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 23:02

Vanadium dioxide (V02) is a typical temperature-controlled phase change material, which undergoes a reversible metal semiconductor phase transition from low temperature monoclinic phase (M phase) to high temperature rutile phase (R phase) at 68 ℃. However, in practical application, 68 is obviously not the appropriate temperature for human beings. Therefore, in order to make vanadium dioxide play a role, it is necessary to reduce the phase transition temperature of vanadium dioxide from 68 to the room temperature (25 ℃), in order to maximize the energy-saving efficiency of vanadium dioxide.

Waste Tungsten Powder Recycle

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 22:56

In the traditional recovery and treatment of waste tungsten powder, the powder waste tungsten powder is first oxidized into tungsten oxide, and then tungsten oxide is dissolved by alkali to form tungstate. In this way, not only the process is complex, but also the efficiency is very low. The oxidation rate of waste tungsten powder is usually less than 50%. Unoxidized tungsten powder needs to be recycled by other methods again. At the same time, because the powder waste tungsten powder is directly treated, the dust in the environment is very large, it is difficult to collect more thoroughly, and also causes a lot of tungsten loss.

sales@chinatungsten.com

sales@chinatungsten.com