Reasons And Solutions For Broken Wire In Middle Wire Cutting

- Details

- Category: Tungsten Information

- Published on Tuesday, 18 December 2018 09:47

In recent years, the accuracy requirements of machine tools for machine tool processing have been continuously improved with the continuous development of China's manufacturing industry. Among them, the precision requirements of wire cutting machine tools are the most urgent. In the online cutting industry, the mainstream “medium wire” is widely used in the fields of mold making, precision small parts, special materials, cams, forming tools and sample processing, because this machine is used to process certain parts. This not only saves time in making stamping dies, but also shortens cycle times and reduces production costs.

Tungsten Steel is Known As "The Diamond in The Metal", Make To Jewelry Can Be Compared With The Diamond.

- Details

- Category: Tungsten Information

- Published on Monday, 17 December 2018 15:00

Many people will travel to Switzerland to buy expensive accessories, such as "unknown, expensive" Swiss watches (Rolex) and so on. You may know that Swiss law has very strict rules on what is “Swiss Made” and “Swiss Made” watches – the movement uses the “Swiss Movement” logo, the quartz label is “Swiss Quartz”, and the watch box is also marked. On the "Swiss Case", even the strap must have "Swiss Strap". It can be said that a real Swiss watch, there is a "Swiss" logo on the body, I am afraid that we do not know that it is Swiss-made. However, I don’t know if you know that the material of these ornaments, tungsten steel, is not produced in Switzerland, but it is actually produced in China. However, it cannot say "speaking hard", "In fact, I am also from China!".

Barium Strontium Tungstate Cathode Manufacturing Scheme

- Details

- Category: Tungsten Information

- Published on Sunday, 16 December 2018 22:56

Barium strontium tungstate cathode as tungstate cathode first appeared in the form of compacted cathode in the 1960s. The cathode is made of barium strontium tungstate (Ba5Sr (WO6)2) as an active material for emission. The synthesized barium strontium tungstate and activator, as well as tungsten powder with a certain size, are pressed and sintered in hydrogen at high temperature.

Unbonded Tungsten Carbide Cemented Carbide Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 16 December 2018 19:17

Unbonded tungsten carbide cemented carbide has better high temperature resistance, wear resistance, corrosion resistance, oxidation resistance and higher hardness than traditional cemented carbide. It is becoming an important development direction of high wear resistant cemented carbide.

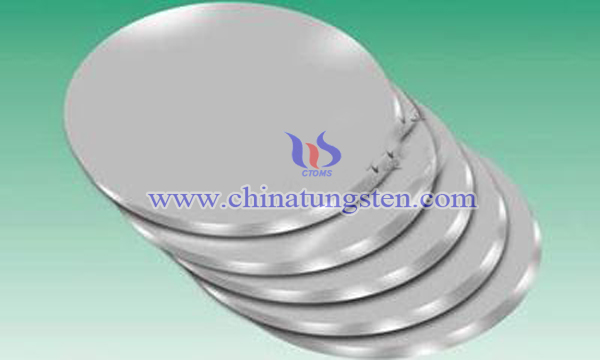

Pure Tungsten Diverter Module Made of Additive Materials

- Details

- Category: Tungsten Information

- Published on Sunday, 16 December 2018 18:43

Additional material manufacturing is a new processing technology, which is different from the traditional "removal" manufacturing. It does not need the original embryo and die. According to the computer three-dimensional model data of parts directly, it can form any complex shape object by adding material layer by layer. Nowadays, people have given the added material manufacturing a fashionable name - 3D printing.

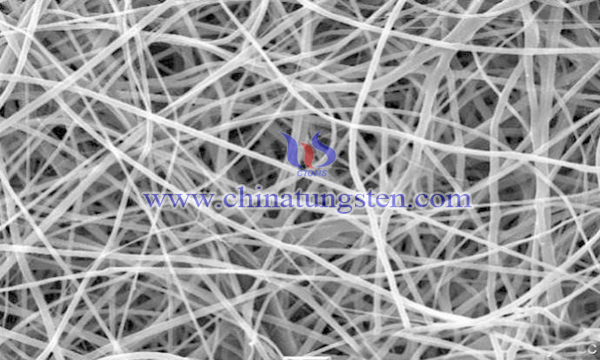

Tungsten Trioxide Nanofibers Preparation by Electrospinning

- Details

- Category: Tungsten Information

- Published on Sunday, 16 December 2018 18:27

Tungsten oxide (WO3) is an indirect bandgap n-type semiconductor material with a band gap of 2.2-2.8eV. It has good absorption of visible light, so it is a very promising semiconductor photocatalyst. In common practice, metal ions are doped into semiconductor photocatalysts, and the recombination of electron-hole pairs can be significantly inhibited by IFCT effect, which can greatly improve the photocatalytic activity of photocatalysts.

High-end Tungsten Catalyst Conversion Ethylene Glycol

- Details

- Category: Tungsten Information

- Published on Sunday, 16 December 2018 15:58

At present, the raw materials of organic chemicals and energy industry mainly come from fossil resources such as coal, oil and natural gas. The depletion of fossil resources and the deterioration of ecological environment force people to seek new ways to synthesize chemicals and fuels from renewable resources.

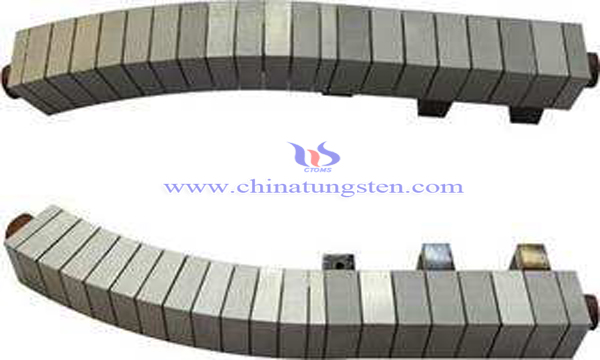

Reconstruction of Tungsten-Nickel Target for Electrochromic Glass

- Details

- Category: Tungsten Information

- Published on Sunday, 16 December 2018 15:32

Chromochromism refers to the phenomenon that the optical properties (reflectivity, transmittance, absorptivity, etc.) of materials change reversibly under the action of external electric field or voltage. Electrochromic materials have wide application prospects in smart windows, anti-glare mirrors, optical information storage and other fields.

High Quality Zirconium Tungstate/Aluminium Alloy Negative Thermal Expansion Material

- Details

- Category: Tungsten Information

- Published on Sunday, 16 December 2018 15:22

Zirconium tungstate (ZrW2O8) is a commonly used negative expansion material, which has high coefficient of negative expansion and wide temperature range. Zirconium tungstate can be prepared separately or added to metal matrix, such as copper or aluminium alloy, to reduce the expansion coefficient of the material. However, in the modern process, excessive preparation temperature and holding time will lead to the decomposition of zirconium tungstate or the reaction between zirconium tungstate and metal, so how to control the interface reaction is also a problem that zirconium tungstate metal matrix composites need to face.

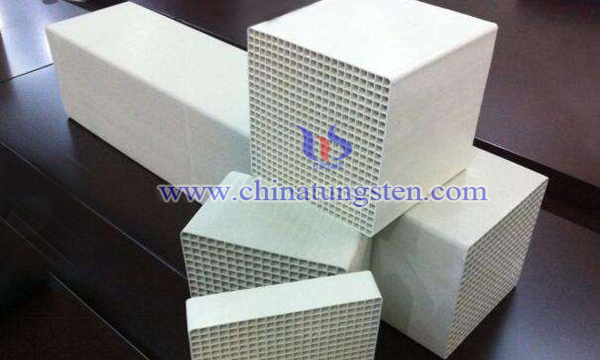

SCR Vanadium Titanium Tungsten Catalyst Recovery

- Details

- Category: Tungsten Information

- Published on Saturday, 15 December 2018 20:39

Nitrogen oxides (NOx) are recognized as one of the major sources of atmospheric pollution, including combustion fumes and automobile exhaust. Monolithic vanadium-titanium based catalysts have been widely used in the removal of NOx from flue gas or tail gas. The NOx can be removed by selective catalysis of NH3 to N2. The catalyst is supported by titanium dioxide (usually 80-90% of the total mass), V2O5 (1-2%) and WO3 (5-10%). Initial investment of catalysts in denitrification projects usually accounts for 30-50% of total investment.

sales@chinatungsten.com

sales@chinatungsten.com