Copper/Bismuth Tungstate Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 15 December 2018 19:02

Bi2WO6 has a narrow visible light response range, easy recombination of photogenerated electrons and holes, short lifetime, low visible light utilization and photocatalytic activity. In view of the defects of Bi2WO6 photocatalytic materials, modification of Bi2WO6 photocatalytic materials and development of new materials with high photocatalytic activity and stable photocatalytic performance are the key to practical application.

Bismuth Cobalt Tungstate Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 15 December 2018 18:50

Global environmental pollution restricts the progress of human civilization, and the elimination of environmental organic pollutants requires a lot of energy, which poses a serious challenge to the increasingly depleted energy. Research shows that almost all organic pollutants can be effectively degraded, decolored and detoxified by semiconductor photocatalysis. Mineralization into inorganic small molecular substances, thereby eliminating environmental pollution and hazards.

Tungsten Copper Lightning Rod, The Patron Saint Of Tall Building

- Details

- Category: Tungsten Information

- Published on Friday, 14 December 2018 09:46

As we all know, lightning is enormously destructive, it produces a powerful current. According to research, the most common linear lightning has a current intensity of tens of thousands to 200,000 amps. Lightning can also cause extreme high temperatures, which can easily lead to forest and house fires. Therefore, in thunderstorms, we often see some towering trees being knocked down by lightning, and some buildings were damaged by lightning. But there are also some buildings that are safe and sound.

Tungsten Alloy Darts - The Best Choice for Professional Darts Players

- Details

- Category: Tungsten Information

- Published on Thursday, 13 December 2018 09:23

The darts movement does not pay attention to the venue, as long as there are darts and targets! Perhaps everyone will think that the throwing of this kind of light-weight equipment is just a matter of throwing away, and playing a small sport for leisure and entertainment. In fact, the darts movement is also a sport that is synonymous with snooker and bowling. It combines competitive, confrontational, casual and entertaining. It is a systemic exercise that is effective and comprehensive for modern office workers. It is simply the nemesis of the mouse hand. It can be non-professional or professional. Non-professional depends on the mood of the equipment, but the professional darts movement is indispensable for tungsten alloy darts.

The speed and power embodied in the darts movement are the skills of "hunting" and "conquering" that humans have never lost. Imagine the ancient hunting position and the action of throwing darts are the same? Although the amount of exercise in the darts is not large, there are certain requirements for the standing posture and the throwing method of the person. You can adjust according to your own situation. Its main feature is to pay attention to the use of the brain and brain, in the calculation to adjust the balance between the left and right brain and the body, that is, the balance between logical thinking and space control.

When the dart is in motion, the joints and muscles of the fingers, wrists, elbows, shoulder joints, deltoids, triceps, wrists, etc. will contract, especially for the training of some smaller muscles that are rarely exercised. Although this training is static, it increases the ability of the nerve to precisely control the muscles. When throwing a dart, the eyes will also aim and relax rhythmically, and the eyes will be relaxed and exercised. So why not play darts often in a busy and busy job? Not only can you adjust your mental state, improve your mental quality, but you can also eliminate fatigue, train your muscles, and exercise your eyes. If you are willing to play with your colleagues and increase your relationship with each other, the darts movement is a good project!

The benefits of darts are many, but the requirements for the venue are relatively low and the equipment is relatively cheap. The commonly used darts include wooden darts, brass darts, nickel alloy darts, and tungsten alloy darts. Wooden darts are the most primitive darts, with darts in softwood, feathers in the tail, and some darts in the collection. Brass darts are lighter and cheaper for beginners and children. Nickel alloy darts are also very light and cheap, but if you are allergic to nickel, it is better to choose carefully. Tungsten alloy darts have excellent performance and can meet the requirements of professional darts. They are used by most professional players to participate in the competition.

Tungsten alloy darts are made of tungsten alloy and have a high density. They are much smaller than other materials of the same weight. The same weight of tungsten alloy darts is half the diameter of brass darts. Its air resistance will be smaller, its linear performance will be better, and it will be more accurate when thrown. Such a delicate and high-weight darts is good for hitting the bullseye. The chances of repeatedly hitting the double or triple area are relatively large, and the possibility of being shot down is also small, which is especially suitable for use in the game.

Tungsten alloy darts have high hardness and are not easily deformed compared with other darts such as brass darts and stainless-steel darts, and can be used for a long time. Its dart part will be engraved with a beautiful knurling or ring, which not only has a decorative effect, but also prevents slipping, and is extremely comfortable in the hand. The hand sweat is calculated, and the tungsten alloy darts are not corroded and damaged because of its good corrosion resistance. In addition, it is also resistant to wear and will retain its radiant appearance after a long period of use. Tungsten alloy darts have such excellent performance, are also non-toxic and environmentally friendly, and will not cause harm to your body. Therefore, it is not wrong to choose it as a dart, and if properly maintained, a set of darts can be used for a lifetime.

- Tungsten Darts Manufacturer & Supplier, Chinatungsten Online: www.chinadart.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten Alloy Fishing Sinkers - The Best Substitute For Lead Fishing Sinkers

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 December 2018 09:56

Lead is the earliest used fishing sink material, and the price is cheap. It is no wonder that many fishing friends used to use lead fishing pendants in the past. However, as we all know, lead is toxic and pollutes water resources. Nowadays, the whole world is promoting environmental protection. Various countries are also promoting environmental protection. They all hope that people can pay more attention to environmental protection, and people's awareness of environmental protection and health is gradually increasing. Therefore, countries have begun to ban the use of lead-made fishing sinkers, and people have begun to use the fishing pendant made of green metal material tungsten alloy. Of course, the advantages of tungsten alloy fishing sinks are not limited to environmental protection.

Application of Tungsten Disulfide in Automobiles

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 December 2018 09:35

Tungsten disulfide is the smoothest new solid lubricant in the current thousands of materials. It has been widely used in the automotive industry, and the benefits to the car are numerous.

Tungsten Steel Engraving Knife: A Knife To Engrave The Sky Below

- Details

- Category: Tungsten Information

- Published on Monday, 10 December 2018 10:01

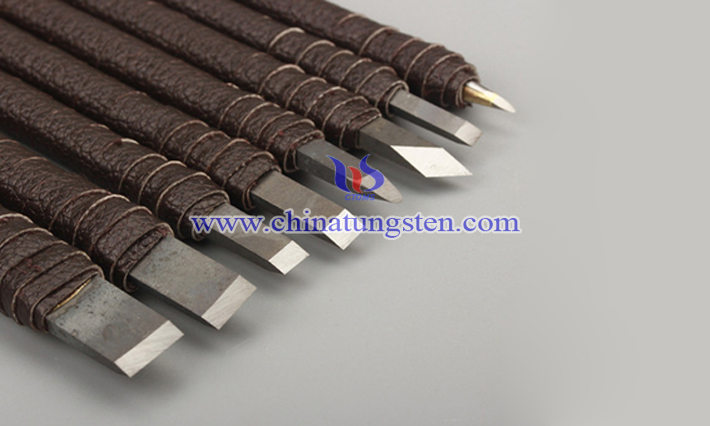

There must be a knife in the engraving, and the engraving knife is an extremely important tool for engraving the seal. For the primary printing friends, the tungsten steel knives can be said to be more suitable for quick start "knife pen". It can be your partner on the road, accompanying you and growing up with you. For the old Indian friends, it is like an old friend. Of course, I believe that the Indian friends also know that the engraving also needs to work hard in terms of lettering, law, rules, and knives.

Tungsten Disulfide/Graphene Nanoribbon Composites

- Details

- Category: Tungsten Information

- Published on Sunday, 09 December 2018 19:36

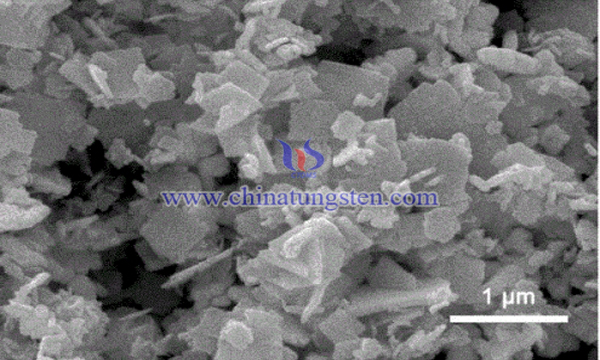

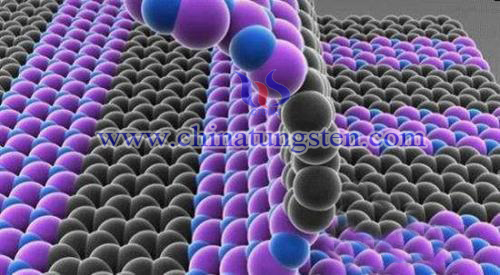

Tungsten disulfide is a typical transition metal chalcogenide. It belongs to hexagonal crystal system. It has a strong S-W-S covalent bond in the layer and a weak van der Waals force between the layers. The thickness of the single layer is about 0.65 nm. Monolayer tungsten disulfide nanosheets can be obtained by stripping or lithium ion intercalation.

Tungsten Wastewater Comprehensive Treatment Strategy

- Details

- Category: Tungsten Information

- Published on Sunday, 09 December 2018 19:14

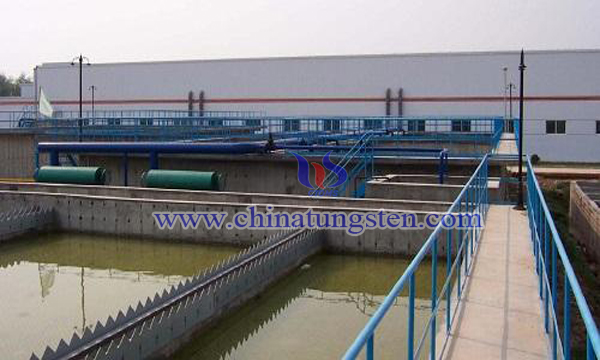

At present, the self-developed ion exchange process is widely used in the production of ammonium paratungstate (APT) in China. Its advantages are stable product quality and easy operation. However, the major disadvantage of this process is that it uses a large amount of water and consumes more than 100 tons of water per ton of APT production. Therefore, the treatment of smelting wastewater is a very headache.

Nano Tungsten Powder Forming by Powder Injection

- Details

- Category: Tungsten Information

- Published on Sunday, 09 December 2018 18:51

Powder injection moulding (PIM) is a new near net-size forming technology developed by combining traditional powder metallurgy with modern plastic injection moulding technology. The most important feature of PIM is that it can directly produce parts with the final shape, minimize the amount of machining and save raw materials, and has wide material adaptability. It has been widely used in the preparation of ceramics and refractory metals.

sales@chinatungsten.com

sales@chinatungsten.com