Tungsten Electrode Enhancement Strategy for High Energy Igniter

- Details

- Category: Tungsten Information

- Published on Sunday, 09 December 2018 18:33

High-energy ignition gas discharge tube is mainly used for high-energy igniter, as a switch to control high-energy, mainly used in military aerospace, airborne, missile-borne engine igniter, also can be used in civil ships, boilers, oil fields and other ignition systems. In military high-energy ignition gas discharge tube technology, China has been banned and blocked by western countries for a long time, and can only rely on independent research and development.

Tungsten Sulfide Nanosheet/Titanium Dioxide Nanoribbon Composite

- Details

- Category: Tungsten Information

- Published on Sunday, 09 December 2018 18:13

In the solar spectrum distribution, ultraviolet light accounts for 5% of the total solar energy. Among them, titanium dioxide is the most typical ultraviolet photocatalyst, but its light absorption is limited to the ultraviolet region. Visible light energy accounts for 48% of the solar spectrum. Bismuth tungstate, bismuth molybdate and other visible photocatalysts have also been widely studied.

Tungsten Alloy Weights Used on Golf Clubs Can With Half The Effort

- Details

- Category: Tungsten Information

- Published on Friday, 07 December 2018 09:26

When it comes to golf, the familiar people can say that the meanings and professional skills of "Birdie", "Eagle" and "Double Eagle" are handy; for the master, they will play a straight one shot. Applying an old saying, that is, for the general, when the "green" battlefield is galloped, the four major slams will be collected. For the above, when the pride is not reduced, after a few years, you can still "laugh". However, what is the relationship between this and the tungsten alloy counterweight? What is the connection between golf clubs and tungsten alloy weights? Do not worry, and listen to the author.

The World's Most Refractory Metal Tungsten and The Most Refractory Materials Containing Niobium Carbides and Nitrides

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 December 2018 09:29

It is well known that tungsten (W) is the purest metal with the highest melting point in the world (meaning it is the most difficult to melt), and its melting point is 3156.85 Kelvin (3430 ° C). At present, the most refractory material in the world is a powder mixture of bismuth-containing carbides and nitrides, which has a melting point of 4400 Kelvin (4126.85 ° C). This was synthesized a few days ago by Russian Far Eastern Federal University and the Far Eastern Branch of the Russian Academy of Sciences under extreme conditions. This high-temperature functional material will be mainly used in cutting-edge fields such as national defense, aerospace, electronic information, energy, chemical, metallurgical and nuclear industries, and has a good application prospect. According to the news released by the Russian Far Eastern Federal University, the next step in the research is to optimize the synthesis of the material and to study the solid phase transition process. Prior to this, the world's most refractory material was the five-carbon tetrakis (Ta4HfC5), which had a melting point of 4,200 Kelvin (3926.85 ° C).

From Cobalt to Tungsten, How Electric Cars and Smartphones Trigger New Gold Rushes

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 December 2018 09:26

Technology products such as smartphones, electric cars, big-screen TVs, and green energy power generation rely on a range of chemical elements that most people have never heard of. Until the end of the 20th century, people were only curious about these high-tech products. But nowadays, I feel that it is uncomfortable to find out which one is missing. This also reflects from the side that these chemical elements are indispensable. Because, in fact, a single mobile phone contains more than one-third of the elements in the periodic table.

Boeing 787 "Dream Window" to Easily Install Your Home? Only Need Tungsten Oxide Electrochromic Film

- Details

- Category: Tungsten Information

- Published on Friday, 30 November 2018 09:43

The Boeing 787 "Dream Window" does not have a visor, but it can change the transmittance. What is similar to this is the tungsten oxide electrochromic film. The porthole of the Boeing 787 has no visor, but it can change the transparency! You only need to press the button, the porthole will become a "chameleon" until it is completely darkened! Of course, the captain can also dim directly from the cockpit when the night falls. In addition, because the color change process of this "electronic curtain" is gradual, you don't have to worry about the eyes being uncomfortable. What's more, when an unexpected power outage occurs, the portholes become completely transparent and comply with relevant aviation standards. At this point, some people may ask, "So, can you easily put the Boeing 787 'Magic Window' home?" This just seems impossible. In fact, only need to - tungsten oxide electrochromic film, this black technology can give you Boeing 787 enjoy!

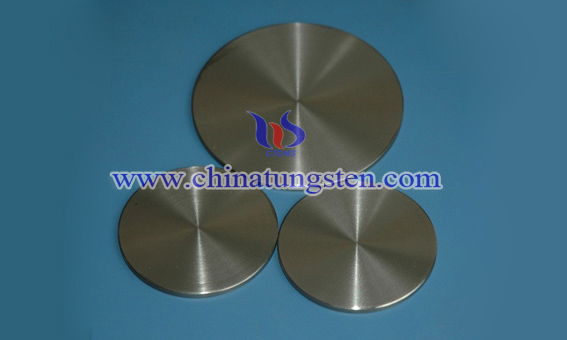

High-purity Tungsten Targets Are Widely Used On Car Chips

- Details

- Category: Tungsten Information

- Published on Thursday, 29 November 2018 09:20

In today's rapid development of the IT industry, the chip can be described as the brain of various data analysis, is the core! Now, for high-purity sputtering targets, the highest-end application area is the field of ultra-large-scale integrated circuit chip manufacturing, which is actually a field of semiconductor chips, and also occupies a large market share. Moreover, the market capacity of semiconductor chips in the future will be further enhanced with the continuous growth of semiconductor chip demand in the terminal consumer field such as automobiles.

Bismuth-doped Tungsten Oxide Powder Preparation

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 November 2018 23:26

Tungsten oxide (WO3) is a kind of functional material, which has been widely studied in photochromic and gas-chromic fields. It has a wide range of applications in the field of photocatalysis and gas sensors. Through the study of bismuth doped tungsten oxide, it is found that the reflectivity of the material to near infrared is more than 95%.

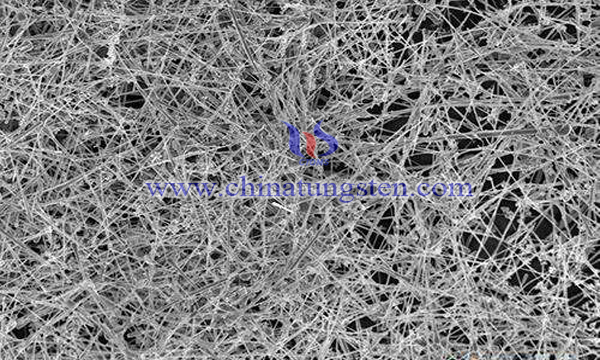

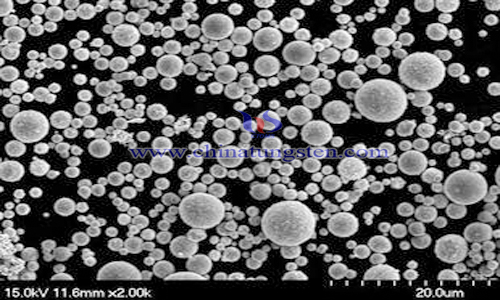

Plasma Spheroidizing Tungsten Powder Scheme

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 November 2018 23:13

Spherical tungsten powder is an important form of tungsten powder. Porous materials prepared from spherical tungsten powder have more uniform pores. In production, the gas permeability of the product can be controlled according to the process, so it will replace the conventional tungsten powder for making porous tungsten components, such as cathodes of high-power pulsed microwave tubes, electronic tantalum tungsten cathodes, gas distribution plates at high temperatures, and gas filtration materials.

SCR Catalyst Recovery Tungsten and Vanadium Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 November 2018 23:06

SCR catalyst is a kind of denitrification catalyst. In the denitrification reaction, the role of SCR catalyst is to promote the selective chemical reaction between reductant and nitrogen oxides in flue gas at a certain temperature. Tungsten vanadium titanium catalyst is the most popular catalyst in our country. Its life span is only 3-5 years. Once discarded, if improperly treated, the active ingredient V2O5, which is a highly toxic substance, will cause secondary pollution to the environment and endanger people's health and life safety.

sales@chinatungsten.com

sales@chinatungsten.com