Plasma Spheroidizing Tungsten Powder Scheme

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 November 2018 23:13

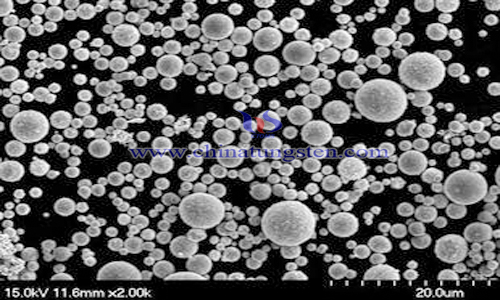

Spherical tungsten powder is an important form of tungsten powder. Porous materials prepared from spherical tungsten powder have more uniform pores. In production, the gas permeability of the product can be controlled according to the process, so it will replace the conventional tungsten powder for making porous tungsten components, such as cathodes of high-power pulsed microwave tubes, electronic tantalum tungsten cathodes, gas distribution plates at high temperatures, and gas filtration materials.

In the field of thermal spraying, spherical tungsten powder has better wear resistance because of its good fluidity and uniform and dense coating. In powder metallurgy process, because the compact of spherical tungsten powder shrinks uniformly during sintering, good size control can be achieved. In addition, the rocket nozzle bushing made of spherical tungsten powder has good fracture resistance and corrosion resistance under thermal stress.

In recent years, plasma as a heat source has great technological advantages in spheroidizing of micron, submicron and some nano-powder materials. The RF plasma torch has large arc body, stable arc current and easy adjustment and control, which makes it easy to be used in the field of ultra-fine powder material treatment technology. The process of preparing spherical tungsten powder by plasma is as follows:

1.Establish a stable argon plasma torch: input 50 slpm, 60 SLPM or 65 SLPM continuous argon gas to the plasma reactor, load the induction coil with high voltage, discharge the igniter at the same time, induction coupling of high voltage coil and corona triggering of igniter, make argon plasma torch produced by ionization of argon gas. At this time, the whole plasma reactor is kept in a negative pressure state, which can ensure the stable operation of the plasma torch.

2. The metal tungsten powder (raw powder) is injected into the high temperature zone of argon plasma torch by carrying gas. Carried gases can be gases such as argon and hydrogen that do not react with metal powders at high temperatures. The heating time ends with the gas-particle flow "flying away" from the plasma torch, and the duration is only 140 milliseconds to 170 milliseconds. Tungsten powder is fed into the high temperature zone of the core of the plasma torch, absorbs a lot of heat, and the surface of the particle begins to melt. When 50% (at least) of the particle weight is melted, tungsten powder particles with high spherical degree are formed due to the effect of surface tension.

3.Spherical tungsten powder is formed by cooling and solidifying the droplets of tungsten powder particles after heating and melting. Under the action of radiation, convection, conduction and chemical heat transfer mechanisms, it is rapidly heated and melted. When the particles melt to at least 50% (calculated by weight), the melted particles form droplets with high spherical degree under the action of surface tension, which are cooled rapidly at extremely high temperature gradient (10-6K/m) and solidified suddenly into the heat exchange chamber, thus forming spherical particles. As long as the technological parameters are set properly, the spheroidization rate can reach nearly 100%.

4. Gas is extracted and spherical tungsten powder is collected. After the spheroidization process is completed, the gas is extracted, treated and discharged, and the spheroidized powder enters the collection tank for automatic metering and collection.

By establishing stable argon plasma and adjusting plasma parameters, tungsten powder raw materials are heated, cooled and solidified, and fine spherical tungsten powder is separated. The tungsten powder obtained has better fluidity, higher density, purity and surface finish than tungsten powder, and the porosity of powder particles is low; tungsten powder can be changed. The shape and spheroidization rate of the particles are high, the apparent density of the powder is increased, the fluidity of tungsten powder is increased, the physical properties of tungsten powder are improved, and the cost is low.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com