How to Produce Tungsten Titanium Powder with Quality and Quantity Guarantee

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 22:47

In the sintering process of tungsten-titanium target, the importance of production of tungsten and titanium powder is obvious. The properties of tungsten titanium powder greatly affect the properties of tungsten-titanium products. With the increasing demand of the market, the production of tungsten titanium powder has not only the requirements of chemical purity, but also the requirements of physical and technological properties. In particular, the preparation technology of ultra-fine tungsten titanium powder for some special purposes needs to be solved.

Weight Reduction Plan for Cerium Tungsten Alloy Wire

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 20:43

Compared with traditional thorium tungsten alloy wire, cerium tungsten alloy wire has lower electron escape work (only 2.8eV, 10% lower than thorium-tungsten alloy wires), higher emissivity (27 times higher than thorium-tungsten alloy wires at 1500K), higher luminescence efficiency (10-15% higher than thorium-tungsten alloy wires), lower arcing voltage (about 40% higher than thorium-tungsten alloy wires), and no human body. The radioactive pollution produced by the body is a good product of green environmental protection. It can be used to replace thorium tungsten alloy wires in electron emission tubes, argon arc welding, etc. It has very broad application prospects in high-demand electric light sources.

Tungsten Oxide / Vanadium Oxide Heterojunction Nanowire Array Gas Sensing Materials

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 20:17

In the 21st century, the level of industrialization has developed rapidly, but the natural environment and ecology on which human beings depend for it have been severely damaged. There are a lot of toxic and harmful gases, smog, acid rain, PM2.5, etc. in the air. Investigating NOx-based toxic gases, the market demands sensors that efficiently and accurately detect and prevent toxic and harmful gases.

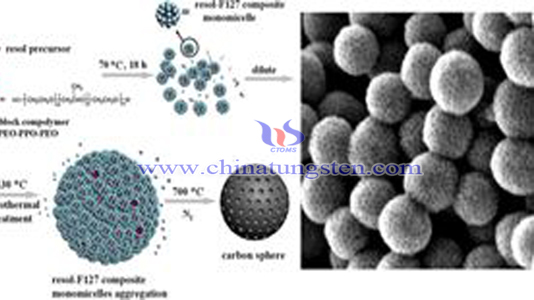

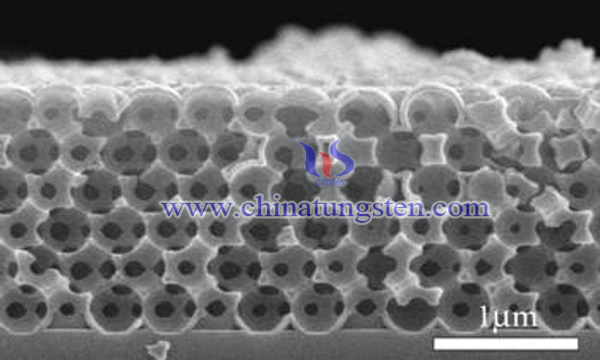

Tungsten Containing Mesoporous Materials Preparation Process

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 20:10

Tungsten containing mesoporous materials have nano-scale homogeneous pore structure and huge surface area. They are a good catalyst carrier. By introducing active components into mesoporous materials, they can provide the active sites needed for catalytic reaction. They have shape-selective catalytic properties and are typical micro-reactor.

Tungsten Nitride-based Ternary Nanocomposite Superhard Film Material

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 19:40

With the development of society, the requirement for materials is higher and higher. In some application fields, materials are required not only to have flexibility and strength, but also to have certain hardness and wear resistance, such as cutting tools in mechanical processing, drills for deep energy exploration, dies used in mechanical manufacturing and cylinder block of engine, etc.. For this reason, people try to use surface modification technology and surface coating technology to not only maintain the high strength and toughness of the material matrix, but also give play to the advantages of super-hard, super-strong and wear-resistant surface coating, thus greatly improving the durability and adaptability of the material.

Ammonium Dithiotungstate Preparation Process

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 19:26

Ammonium dithiotungstate (NH4) 2WO2S2 is an important thiometallic ammonium salt. After thermal decomposition, transition metal chalcogenide tungsten disulfide WS2 can be obtained. It can be used in the synthesis of tungsten iron sulfur cluster compounds, semiconductors, superconductors, photoelectrochemical solar cells, hydrogen storage materials and electrode materials. It has good application and is the precursor of coal liquefaction and heavy oil hydrogenation catalysts. It can also be used as raw materials for the preparation of supported and non-supported tungsten sulfide hydrogenation catalysts. Therefore, it is of great significance to develop a high yield method for the preparation of high purity ammonium dithiotungstate.

Hurricane of The 21st Century, The F-22 Fighter Plane Was Hit Hard, The Chinese Rare Earth "Cooked"

- Details

- Category: Tungsten Information

- Published on Friday, 09 November 2018 09:39

Recently, the United States is looking around for alternatives to China's rare earths. In addition, a hurricane hit the US state of Florida, causing damage to almost half of the F-22 aircraft in the base. It seems that the "Eagle Eye" filmed by NASA is not only "eyelid" and "eyes", but the power is also sufficient. Worse, these fighters are "invisible", so that the current count of damage is still in progress. Up to now, there are more than 20 damaged points. According to military experts, is this loss worth hundreds or even thousands of Lamborghini? It seems that this loss is a bit big. So, now, it is estimated that the F-22 production line is waiting for the rare earth to “open the pot”.

The New Generation of Structural Ceramics is Becoming Popular

- Details

- Category: Tungsten Information

- Published on Thursday, 08 November 2018 22:24

Structural ceramics have maintained a strong and sustained growth in the past few years. This growth in demand stems not only from the growth of many different applications, but also from the exploration and attention of people to the science of ceramic materials. As demand continues to grow, people need stronger, more durable, lighter, and more heat-resistant materials to accomplish more impossible tasks. Material manufacturers must seek new innovative processes to produce the next generation of ceramics.

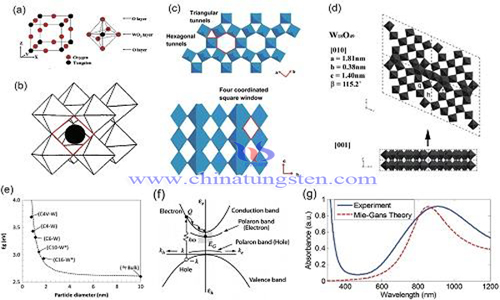

Hexagonal Tungsten Oxide Preparation by Solid Phase Method

- Details

- Category: Tungsten Information

- Published on Thursday, 08 November 2018 22:05

The hexagonal tungsten oxide has attracted much attention because its single crystal has an empty hexagonal space tunnel structure. W in the compound exists in the mixed valence states of W6+, W5+ and W4+, thus making the charge balance of the compound as a whole. This unique spatial structure and special valence state make it have good optical effect.

Direct Reduction of Spherical Tungsten Powder with Old Routines

- Details

- Category: Tungsten Information

- Published on Thursday, 08 November 2018 21:47

Spherical tungsten powder is widely used in powder metallurgy processes such as preparation of porous materials, thermal spraying and injection moulding. Porous tungsten prepared with spherical tungsten powder has more uniform pore, so it is gradually replacing conventional tungsten powder to make porous tungsten components, such as cathode of high power pulse microwave tube, barium tungsten cathode of electron tube, sweating material of rocket, carrier of catalyst or catalyst, etc.

sales@chinatungsten.com

sales@chinatungsten.com