Modification of Lead Tungstate Crystal by Ion Diffusion Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 October 2018 22:19

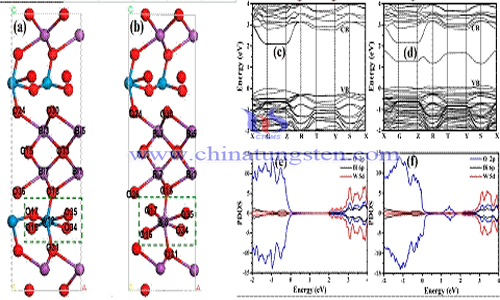

As a new type of scintillation crystal, lead tungstate crystal (PbWO4) has been used by European Center for Nuclear Research (CERN) for its high density (8.28g/cm3), short radiation length (0.87cm) and Moliler radius (2.12cm), fast scintillation attenuation time (t < 50ns), strong radiation damage resistance and low cost. The precise electromagnetic calorimeter (ECAL) of the Large Hadron Collider (LHC).

Silver Tungstate / Silver Bromide Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 October 2018 22:06

In the field of pollutant degradation and energy production, semiconductor photocatalysis is one of the most promising methods. In order to find efficient photocatalysts, a large number of studies have focused on the Factors Affecting Photocatalytic activity.

Preparation of Hollow Porous Tungsten Oxide Spheres by Spray Drying

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 October 2018 21:55

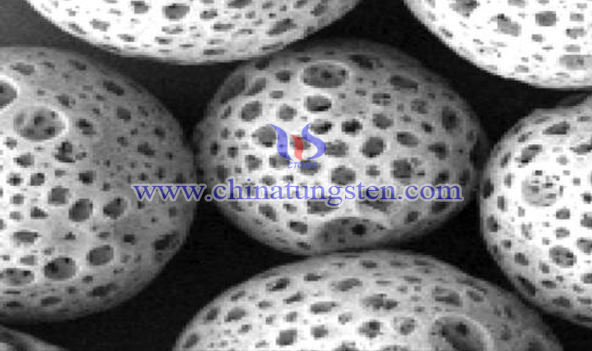

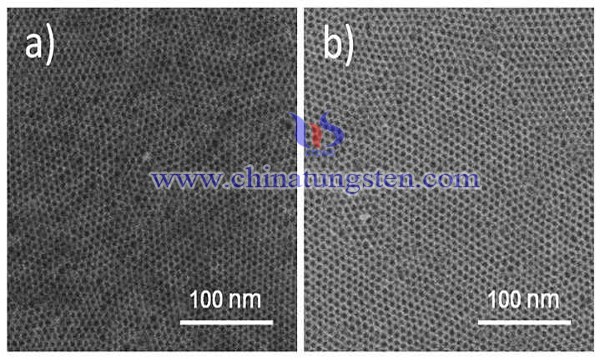

Tungsten oxide has many symmetrical n-type semiconductor materials, such as hexagonal, cubic and so on. In particular, nano-tungsten oxide has a large specific surface area, and its volume effect, surface effect, quantum size effect and macroscopic quantum tunnel effect are significant, which makes its application areas continue to expand. It can be used as solar energy absorption materials, stealth materials, photocatalytic materials and gas sensitive materials such as NOx, H2S, NH3, etc.

5G Era Will Bring Tremendous Development Opportunities to China's IC Industry

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 October 2018 10:08

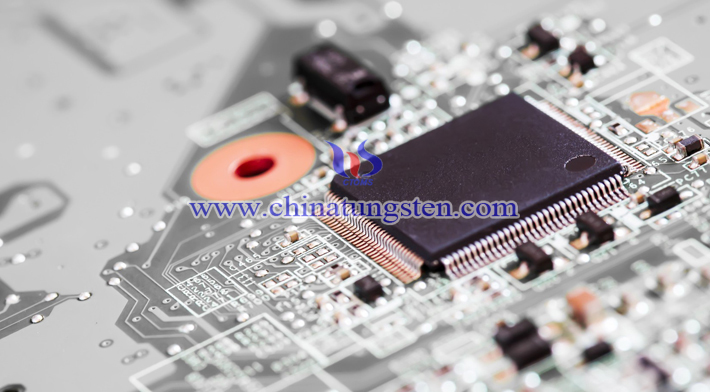

Recently, the "2018 China Chip Development Summit Forum" was held in Nanjing. At the meeting, Zhao Weiguo, chairman of the Ziguang Group, said: "It is estimated that in the next five years, the Chinese integrated circuit industry will basically be able to stabilize the heel."

He also said that "Chinese integrated circuits will have a place in the world by 2028 or around 2030."

What is a place?

He said, "There is one in three cents or four cents."

In this forum, Ziguang also signed the "Building 5G Industry Ecology Proposal" together with 17 manufacturers including Intel, ARM, Hisense, TCL, ZTE, Gome and Coolpad Group. This means that as the 5G is about to be commercialized, the new ecology is already accelerating brewing and formation.

I believe that you will not miss this news if you are always concerned about the IT industry. I believe that you know that the current IC industry is booming! Then you must know what the key directions of the integrated circuit industry in 2018 are?

This year, the three major areas of concern for the IC industry are artificial intelligence, memory and the Internet of Things.

Artificial intelligence is regarded as an important technology that will change the development process of human society. Of course, the artificial intelligence industry is the foundation of artificial intelligence industry. The domestic memory industry will eventually usher in a decisive moment in 2018. At the same time, the Internet of Things application will also be driven by the dual benefits of domestic consumption upgrades and industrial transformation, ushered in a new round of development climax.

When it comes to integrated circuits, I have thought of tungsten-copper composites. Moreover, in recent years, tungsten-copper composites have been widely used in large-scale integrated circuits because of their high thermal conductivity and electrical conductivity. As an electronic packaging material, the high thermal conductivity and heat resistance of the tungsten-copper composite material greatly increase the power consumption of the microelectronic device and miniaturize the device. In addition, the thermal expansion coefficient of tungsten copper makes it well matched with semiconductor materials such as silicon wafers and gallium arsenide in ceramics and ceramic materials for tubes.

Of course, the application of tungsten-copper composites can be used not only in the integrated circuit industry, but also in military defense. Because tungsten-copper composites are resistant to high temperatures, thermal shocks, and erosion, they meet the requirements of high-tech and military defense materials. Such applications generally use tungsten-copper composite materials with ω(Cu)=5%~10%. The tungsten skeleton pores have good connectivity and good capillary action to ensure that copper can be used well at high temperature. Without causing too much volatile loss.

In other words, China's IC market demand accounts for about 63% of the world's total, and is the world's largest integrated circuit market. Throughout the moment, China's IC industry continues to maintain rapid growth, and technological innovation capabilities are also constantly improving. However, China's IC industry still faces many challenges. Fortunately, there are still a lot of news of striding forward. For example, CEC China Electronics, the backbone of China's electronics industry, is also constantly transmitting news on the layout of integrated circuit projects.

The author believes that, as Zhao Weiguo, chairman of Ziguang Group, said, the arrival of the 5G era will bring huge opportunities for the development of China's integrated circuit industry, especially in recent years, such as mobile chips. I hope that in the near future, on the winding road of developing integrated circuits, Chinese enterprises can grow into giant companies.

- Tungsten Copper Manufacturer & Supplier, Chinatungsten Online: tungsten-copper.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten Steel Tactical Pen

- Details

- Category: Tungsten Information

- Published on Monday, 29 October 2018 10:09

The tactical pen, also called the tactical self-defense pen, as its name, looks like a pen in appearance, but there are quite a lot of mystery inside. As stated on the Internet, the tungsten steel tactical pen can be described as “black technology”. It is not just an ordinary pen for daily writing. It is a multi-functional machine, such as self-defense, writing, lighting, window breaking and even Open the bottle and so on, it is not too much to describe it.

Where does the tactical pen originate?

The design of the tactical pen originated from abroad. We all know that until now, whether it is domestic or foreign, there are some controls on the self-defense equipment in law. What's more, when the tactical pen was just designed. Moreover, the original intention of the tactical pen was designed because – in American law, if it is self-defense with a knife, it is regarded as self-defense and not guilty; but if it is self-defense, it is risky and is judged to be intentionally wounded. This is because, in the United States, knives are considered a tool, and crowbars are an offensive weapon. Thus, the tactical pen is just a tool, not a weapon.

What are the components of the tungsten steel tactical pen?

Moreover, the components of the tungsten steel tactical pen are not the same. They are composed of a pen head, a pen body, a tungsten steel head, a pen cover and a survival whistle. They have a tungsten steel attack head, a self-defense knife, a refill, an emergency pen, and illumination. The lights, and even some have the function of a bottle opener.

What are the characteristics of tungsten steel tactical pens?

In terms of hardness, tungsten steel tactical pens are comparable to diamonds, with Mohs hardness of 9 or more. Of course, the tungsten steel tactical pen is not only high in hardness, but also has a series of features superior to ordinary aluminum alloy and stainless steel - wear resistance, high strength, corrosion resistance, high toughness and good weather resistance.

What can a tungsten steel tactical pen be used for?

The plot in the movie is another world that we can't match. Go back to everyday life and talk about the use of tungsten steel tactical pens. Usually, the functions of the tactical pens we often use are mainly writing and lighting. As for the close defense and emergency escape, it is an emergency application.

Apply an old saying, that is, writing and lighting are often there, close defense and emergency escape are not common! But another old saying tells us that "you can't stop the sudden coming of a disaster, but you can be prepared to deal with it at all times." That is, although it is not always a good thing, in the case of dangers and accidents, At such a critical moment, how can you not have personal protection?

As a close-fighting defense tool, in the case of outdoor distress and personal safety control, first enable the whistle function on the tungsten steel tactical pen to directly call for help. In the case of a disparity between the enemy and the enemy and highly likely to threaten life safety, consider the use of the self-defense knife function on the tactical pen.

As an emergency escape tool, it can also be said to be a tool for breaking the window. The tungsten steel tactical pen is used when the car encounters an accident such as rollover, spontaneous combustion or flood, and the door of the car is interrupted or the door is not opened. At this point, the tungsten steel tactical pen can easily crush the tempered window glass and gain some time for escape.

The application of tungsten steel tactical pen, known as "Black Technology", is not limited to this. More importantly, the subsequent development of tactical pens, especially in military applications, will not stop there.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Australia: One of The Largest Rare Earth Phosphate Deposits in The World

- Details

- Category: Tungsten Information

- Published on Friday, 26 October 2018 09:28

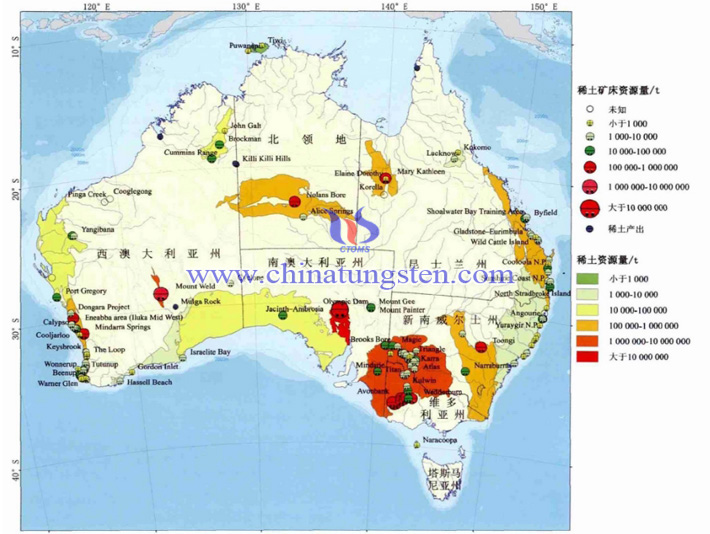

As you may know, Australia's rare earth resources are quite rich and diverse. But you know that there is a rare earth phosphate deposit in central Australia - one of the largest and most intensive phosphate deposits in the world. The deposit is expected to have a mine life of 30 years and is estimated to contain 580,000 tons of rare earth (3.1% REO), of which Nd and Pr are high, and Nd is about 20%. Second; Pr accounts for about six percent. Not only that, but it also has 8.7 million pounds of uranium and about 70,000 tons of lanthanum oxide (0.36% ThO2). According to statistics, Australia has proven that rare earth reserves rank fourth in the world.

Speaking of Australia's rare earth resources, it is natural to understand the characteristics of its rare earth deposits - various types, all regions. However, the resources occupied by different types of deposits are not balanced. The types of deposits and the amount of resources occupied are as follows: the rare earth deposits associated with sedimentary basins can be divided into three types: phosphorite, lignite and unconformity-related types, and their resources are insufficient for all Australian resources. One of the points; the amount of rare earth deposits related to epigenetic weathering accounts for about 3% of the total Australian resources; the heavy mineral sand type rare earth deposits account for 6% of the total Australian resources; and related to magma the six deposits account for about 90% of the total Australian resources.

You may not be very clear about the rare earths in the rare earth industry. Next, let's take a closer look at the knowledge of rare earths.

We all know that the so-called rare earth is called "rare earth", but it is not rare or "soil". It is a collection of seventeen chemical elements. It is called "industrial vitamin" and also has "industrial gold". It is widely used in energy, electronics, military, chemical, metallurgy, machinery, light industry, environmental protection and agriculture. Moreover, in recent years, the strategic position of rare earths has become increasingly prominent due to the gradual increase in dependence of emerging industries. Among them, tantalum and niobium play a vital role in the electronic technology and automotive industries because they are key raw materials for ultra-high strength permanent magnets. For example, high purity niobium oxide is mainly used in the production of advanced magnets and magnetic alloys.

Therefore, it is not unusual for the global demand for rare earths to increase year by year. Correspondingly, the annual global rare earth production is lower than the annual demand. In recent years, there is a certain gap in the demand for rare earths every year. Therefore, the development of rare earth deposits in recent years has become more and more important for the supply of rare earth materials with the increasing exploitation and consumption of rare earth resources in the world.

Going back to the domestic market. At present, China supplies more than 90% of the world's rare earths. More importantly, about 90% of the rare earth consumed by the US military is produced in China. However, a few days ago, the United States passed a new defense bill that banned its Ministry of Defense from buying rare earth magnets from China. However, recently, the plot has undergone a major reversal. Compared to the tariff list in July, the latest list completely removes rare earth metals, rare earth oxides, rare earth compounds and metal permanent magnets (including neodymium iron boron). According to industry analysts, this may be because the United States has a high degree of dependence on China's rare earths, which has caused concern, and then has the performance of removing rare earth materials and adding tariff lists.

Rare earth is known as the industrial "gold". Because of its excellent physical properties such as light electromagnetics, it can form new materials with different properties and various kinds of materials. Its most remarkable function is to greatly improve the quality and performance of other products. For example, the tactical performance of steel, aluminum alloy [color business opportunity: aluminum alloy door and window price], magnesium alloy and titanium alloy used for manufacturing tanks, airplanes and missiles is greatly improved. Moreover, rare earths are also high-tech lubricants such as electronics, lasers, nuclear industry, and superconductors. Once used in the military, rare earth technology will inevitably bring about a jump in military technology. In a certain sense, the US military’s overwhelming control in several local wars after the Cold War and the unscrupulous public killing of the enemy are due to the superhumanity in the field of rare earth technology.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Endangered Chinese Medicine: Tungsten Alloy Fire Needle Therapy

- Details

- Category: Tungsten Information

- Published on Thursday, 25 October 2018 09:28

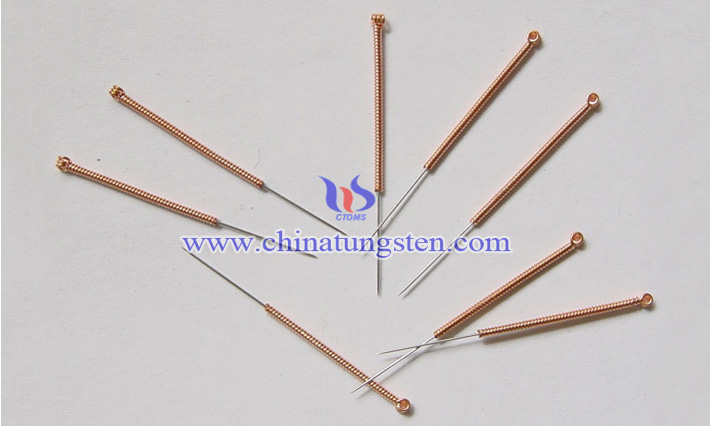

The Chinese medical law has five mainstream treatments: “needle, moxibustion, cans, medicine, and massage”. It can be said that these mainstream Chinese medicine treatments are valuable medical experiences that my Chinese medical scientists have accumulated in the long-term struggle against diseases. Among them, the history of fire acupuncture in acupuncture can be said to have a long history and a long history of more than 2,000 years. Fire needle therapy has the characteristics of simple operation, low cost, quick effect, good curative effect, wide indication and high safety, so it has been loved by the masses. However, it is also an ancient Chinese medicine treatment technology that is almost endangered. Even if some medical practitioners say that it can cure almost all diseases, some doctors say that the tungsten alloy fire needle used in this therapy has excellent performance.

Mesoporous Tungsten Carbide Synthesis

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 October 2018 22:18

Nano-tungsten carbide (WC) is a kind of non-noble metal catalytic material with excellent performance. It has been reported that the surface electron layer of WC is similar to platinum (Pt) and has Pt-like catalytic activity in some reactions. WC not only has the characteristics of replacing platinum and other precious metal catalysts and good anti-poisoning ability, but also has strong acid resistance and good electrocatalytic activity. However, how to further improve the catalytic activity of WC is one of the main problems in the preparation of WC catalyst.

How to Improve The Thermal Conductivity of Tungsten Copper Heat Sink

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 October 2018 22:10

More than 60% of the cost of high-end semiconductor electronic devices, including LED, laser and microwave power devices, comes from packaging, and the key to packaging technology is heat dissipation. Heat dissipation not only affects the cost, but also affects the performance of semiconductor devices.

Bismuth - Bismuth Tungstate Ternary Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 October 2018 21:34

As photochemical smog, acid rain and ozone layer destruction pollutants, nitrogen oxides have become an urgent air pollutant in the world. As an environmentally friendly green technology, visible light-driven photocatalysis has shown a good application prospect in environmental pollution purification and solar energy conversion.

sales@chinatungsten.com

sales@chinatungsten.com