High Quality Tungsten Molybdenum Alloy Preparation by Multielement Doping

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 July 2018 21:29

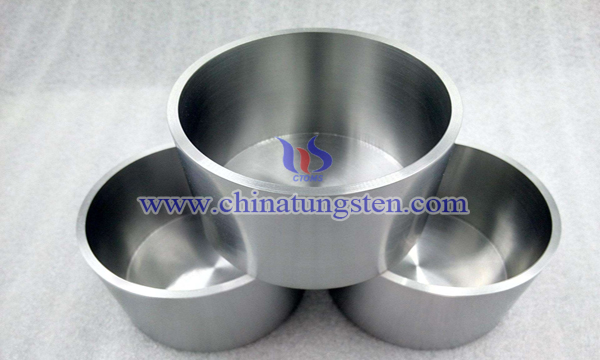

Tungsten and molybdenum alloys have excellent corrosion resistance to liquid zinc and are used to make agitators, pipes and container liners and other components in zinc smelting industry. It can be used as a high temperature component in rocket and missile, the filament of the electron tube, parts and other high temperature materials for the corresponding high temperature conditions.

Tungsten and molybdenum alloys have the disadvantages of large brittleness and poor processing properties. They need to be doped with other elements. The common doping elements are lanthanum, rhenium, vanadium and praseodymium. The general doping process is as follows:

According to the mole ratio of Pr:Re:Mo=1:1:0.5, take praseodymium nitrate, rhenium nitrate and ammonium molybdate in the citric acid solution of 0.1mol/L of molar concentration to form a mixed solution, then add nitric acid to adjust the pH to 1 of the mixed solution, heat the mixed solution at 100°C to prepare the sol. The sols are heated by 120°C in turn 0. The solid powder was obtained by heating 2~8h and 600°C. The doped molybdenum powder was prepared by reduction of solid powder and calcination of 20min at 1450°C.

The reduction treatment of solid powder is that the solid powder is placed in a hydrogen reduction furnace and treated for 6h, the mixed powder containing molybdenum oxide is obtained, the flow rate of hydrogen is 15m/s, the hydrogen dew point is -70°C, the five temperature zone reduction system is adopted. The temperature of each temperature zone is at 530°C, 550°C, 580°C, 600°C and 620°C. The mixed powder containing molybdenum oxide was treated with hydrogen, the mixed powder containing molybdenum powder was obtained for 8h. The hydrogen flow rate was 35m/s, the hydrogen dew point was -75°C. The temperature of each temperature zone was 750°C, 800°C, 850°C, 900°C and 950°C.

According to the molar ratio of La:W=1:0.25, lanthanum nitrate and tungsten oxide are taken in turn, lanthanum nitrate is dissolved in water, lanthanum nitrate solution of 0.4mol/L concentration is formed. The lanthanum nitrate solution is doped into tungsten oxide by spray method, then the sodium hydroxide solution of 1.2mol/L is added to pH 9. The filtrate was dried at 110°C, then calcined 2.1h at 880°C and H2 atmosphere to produce doped tungsten powder.

According to the mass percentage, 87.5% doped molybdenum powder, 11% doped tungsten powder and 1.5% vanadium oxide are taken respectively. Then doped molybdenum powder, doped tungsten powder and vanadium oxide will be added into the mixing machine to mix for 24h, the diffusion of the vacuum drying container is used, the speed is 100r/min, the cold isostatic pressing of 20min under 220MPa is carried out. Tungsten and molybdenum alloys were prepared by sintering for 22h at 2150°C.

Tungsten compounds are preferred to be blue tungsten. After hydrogen reduction, the tungsten molybdenum alloys not only have excellent high temperature creep resistance, tensile strength, but also have good low temperature strength. As lanthanum oxide and praseodymium oxide are plastic deformed, they are dispersed into fine second phase particles at higher temperatures and rule rows.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com